Metal racks provide sturdy support and allow better airflow around pet treats during dehydration, promoting even drying and preventing mold growth. Stackable dehydrator trays maximize vertical space, increasing the volume of treats processed at once but may restrict airflow between layers, potentially leading to uneven drying. Choosing between metal racks and stackable trays depends on the balance between capacity needs and optimal air circulation for consistent dehydration results.

Table of Comparison

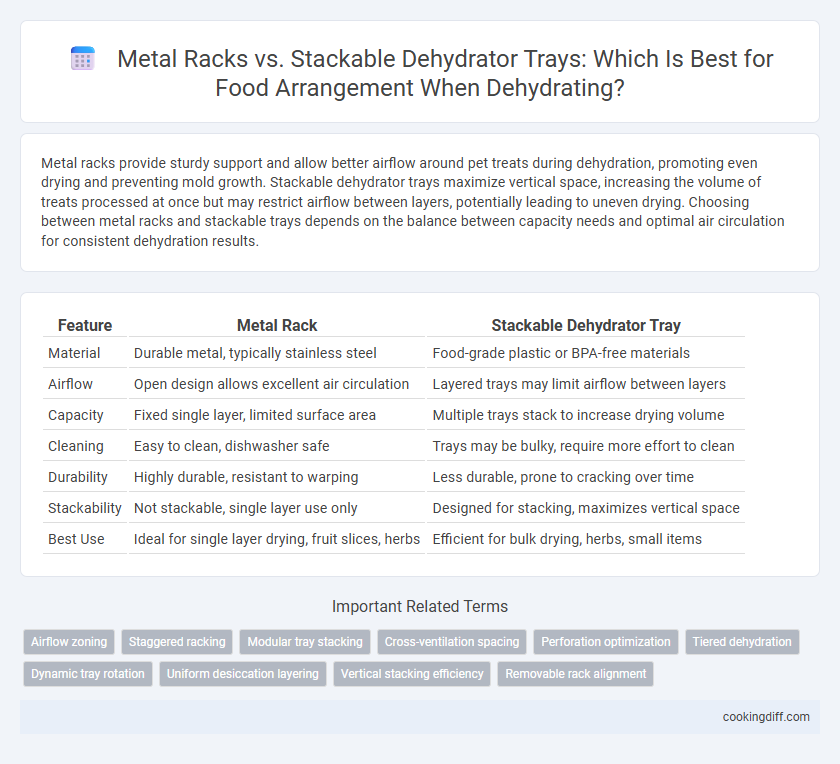

| Feature | Metal Rack | Stackable Dehydrator Tray |

|---|---|---|

| Material | Durable metal, typically stainless steel | Food-grade plastic or BPA-free materials |

| Airflow | Open design allows excellent air circulation | Layered trays may limit airflow between layers |

| Capacity | Fixed single layer, limited surface area | Multiple trays stack to increase drying volume |

| Cleaning | Easy to clean, dishwasher safe | Trays may be bulky, require more effort to clean |

| Durability | Highly durable, resistant to warping | Less durable, prone to cracking over time |

| Stackability | Not stackable, single layer use only | Designed for stacking, maximizes vertical space |

| Best Use | Ideal for single layer drying, fruit slices, herbs | Efficient for bulk drying, herbs, small items |

Introduction to Dehydrating: Metal Racks vs. Stackable Trays

Dehydrating efficiency depends significantly on the type of arrangement used, with metal racks and stackable trays offering distinct advantages in airflow and space management. Choosing the right arrangement can enhance drying speed and product quality.

- Metal racks provide superior airflow - Their open design allows hot air to circulate freely around the food, enabling even dehydration.

- Stackable trays maximize space - These trays are compact and convenient for drying multiple batches simultaneously in a limited area.

- Material durability varies - Metal racks are generally more durable and heat resistant compared to plastic stackable trays.

Material Matters: Metal Rack Durability vs. Plastic Trays

Metal racks offer superior durability and heat resistance compared to plastic stackable dehydrator trays, which may warp under high temperatures. Material selection significantly impacts the longevity and safety of food drying equipment.

- Metal rack durability - Constructed from stainless steel or aluminum, metal racks withstand repeated heat exposure without deforming.

- Plastic tray limitations - Plastic trays often soften or crack due to prolonged heat, reducing lifespan and risking contamination.

- Heat conductivity - Metal racks provide even heat distribution, enhancing drying efficiency compared to plastic trays.

Choosing metal racks ensures a longer-lasting, safer dehydration process due to their resilient material properties.

Airflow and Even Drying: Which Option Wins?

Metal racks offer superior airflow due to their open wire design, allowing hot air to circulate evenly around the food, which results in more consistent drying. Stackable dehydrator trays, while space-efficient, can sometimes restrict airflow between layers, causing uneven drying and longer dehydration times.

Choosing metal racks is ideal for achieving uniform moisture removal and preventing spoilage during dehydration. Though tray stacks maximize capacity, their limited ventilation often compromises drying quality and airflow efficiency.

Space Efficiency: Stackability Compared

Metal racks offer sturdy support but occupy more horizontal space, limiting overall stackability in dehydrators. Stackable dehydrator trays maximize vertical space utilization, allowing multiple layers of food items without increasing the footprint.

- Metal rack stability - Provides strong support but reduces ability to stack tightly due to frame design.

- Stackable tray compactness - Designed to nest efficiently, optimizing vertical dehydration area.

- Space efficiency comparison - Stackable trays enable better use of dehydrator volume compared to bulkier metal racks.

Cleaning and Maintenance: Ease of Use

| Metal Rack | Metal racks are durable but often require thorough scrubbing to remove sticky residues, making cleaning more labor-intensive. Their open structure allows better airflow but can trap debris in corners, complicating maintenance. Use of non-abrasive brushes and mild detergents prolongs rack life while ensuring hygiene. |

| Stackable Dehydrator Tray | Stackable trays are usually made from dishwasher-safe plastic or silicone, offering easier cleaning and quicker drying times. Their modular design simplifies removal and washing, reducing maintenance effort significantly. Smooth surfaces and fewer crevices minimize food residue buildup for enhanced ease of use. |

Capacity and Batch Size Considerations

Which option offers greater capacity and flexibility for large batch dehydration? Metal racks typically provide sturdier support and allow for larger, more evenly spaced items, making them ideal for bigger batches. Stackable dehydrator trays maximize vertical space but may limit batch size due to smaller surface areas and potential airflow obstruction between layers.

Arrangement Flexibility for Different Foods

Metal racks offer sturdy support and allow air to circulate evenly around larger or denser foods, making them ideal for dehydrating items like meats and thicker vegetable slices. Stackable dehydrator trays provide flexibility by enabling customized layering for smaller or similarly sized foods such as herbs and fruits, maximizing drying efficiency.

Metal racks typically have fewer layers but accommodate heavier loads, ensuring consistent heat distribution across diverse food types. In contrast, stackable trays can be rearranged or separated to suit the drying needs of delicate items without mixing flavors or textures. This adaptability in tray arrangement enhances the overall dehydrating process for various food categories, promoting optimal moisture removal and texture preservation.

Temperature Distribution and Consistency

Metal racks provide superior airflow and even temperature distribution, ensuring consistent drying across all layers. Stackable dehydrator trays can create uneven heat zones, causing variation in moisture levels and extended drying times. Optimal arrangement with metal racks enhances uniformity, reducing the risk of under- or over-dehydrated food products.

Longevity and Replacement Costs

Metal racks offer superior durability and can withstand high temperatures without warping, resulting in a longer lifespan compared to stackable dehydrator trays. Their robust construction minimizes the frequency of replacements, reducing long-term costs significantly.

Stackable dehydrator trays, often made from plastic, may degrade faster due to heat exposure and frequent cleaning, leading to more frequent replacements. Although initially cheaper, their replacement costs accumulate over time, making metal racks a more cost-effective solution for sustained use.

Related Important Terms

Airflow zoning

Metal racks provide superior airflow zoning during dehydration by allowing air to circulate freely around each layer, promoting even drying and preventing moisture buildup. In contrast, stackable dehydrator trays often restrict airflow between layers, which can lead to uneven dehydration and extended drying times.

Staggered racking

Staggered racking with metal racks enhances airflow efficiency by allowing better circulation around each tray compared to stackable dehydrator trays, reducing drying times and promoting uniform dehydration. Metal racks provide adjustable spacing options that prevent overlapping and clumping, optimizing the arrangement for large batches of fruits, vegetables, or herbs.

Modular tray stacking

Metal racks offer sturdy support and better air circulation for modular tray stacking in dehydrators, enhancing even drying of food items. Stackable dehydrator trays optimize space efficiency by allowing customizable layering, but may require careful arrangement to prevent airflow obstruction and ensure uniform dehydration.

Cross-ventilation spacing

Metal racks provide superior cross-ventilation spacing compared to stackable dehydrator trays, allowing air to circulate evenly around food items for consistent drying. Stackable trays often restrict airflow between layers, which can lead to uneven dehydration and longer drying times.

Perforation optimization

Metal racks provide larger perforations that enhance air circulation, promoting even dehydration across thicker or denser food items. Stackable dehydrator trays feature smaller, evenly spaced perforations optimized for delicate or smaller pieces, ensuring consistent moisture removal without item displacement.

Tiered dehydration

Metal racks offer superior airflow and heat distribution in tiered dehydration setups, ensuring even drying across multiple layers compared to stackable dehydrator trays. Stackable trays, while space-efficient, can restrict airflow between tiers, potentially leading to inconsistent moisture removal and longer drying times.

Dynamic tray rotation

Metal racks provide sturdy support and allow air to circulate evenly, but lack dynamic tray rotation, which can result in uneven drying. Stackable dehydrator trays with dynamic rotation optimize airflow and improve drying uniformity by continuously moving the trays during the dehydration process.

Uniform desiccation layering

Metal racks provide sturdy separation but may cause uneven airflow and potential hotspots during dehydrating, while stackable dehydrator trays optimize uniform air circulation by allowing consistent spacing and layering, ensuring more uniform desiccation of food items. Proper arrangement using stackable trays improves drying efficiency by facilitating balanced heat distribution across all layers.

Vertical stacking efficiency

Metal racks offer sturdy support and maximize vertical stacking efficiency by allowing better airflow between layers, enhancing uniform drying in dehydrators. Stackable dehydrator trays are designed for compact storage but may limit airflow compared to metal racks, potentially reducing dehydration speed and consistency.

Metal rack vs Stackable dehydrator tray for arrangement. Infographic

cookingdiff.com

cookingdiff.com