Microwave drying preserves herb flavors quickly by using rapid heat, but it risks uneven dehydration and potential nutrient loss. Vacuum dehydrators maintain low temperatures and oxygen-free conditions that protect delicate compounds and extend shelf life. Choosing between the two depends on prioritizing speed with possible quality trade-offs or optimal preservation with longer processing time.

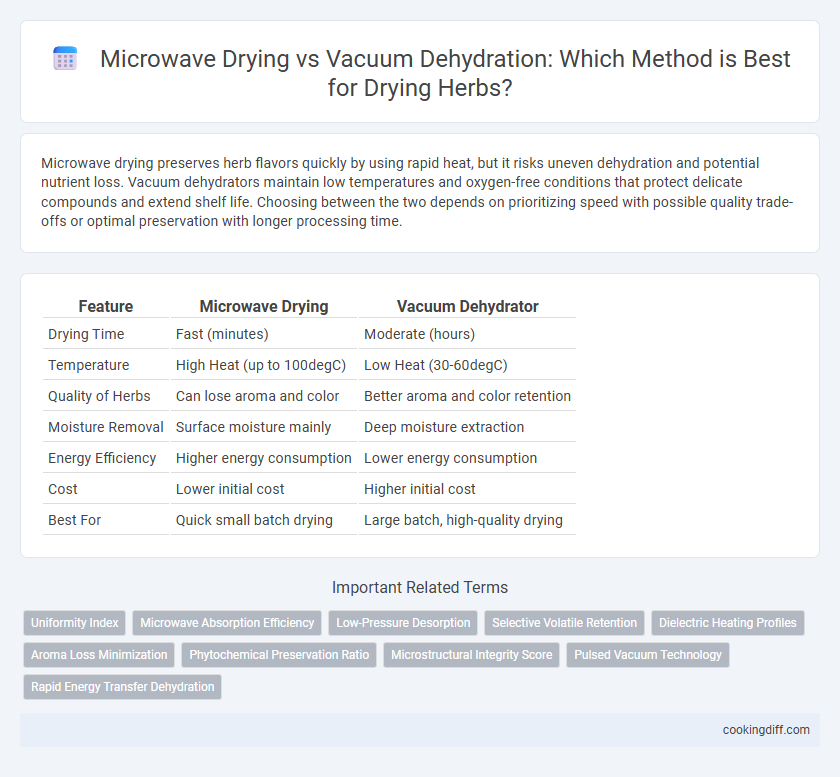

Table of Comparison

| Feature | Microwave Drying | Vacuum Dehydrator |

|---|---|---|

| Drying Time | Fast (minutes) | Moderate (hours) |

| Temperature | High Heat (up to 100degC) | Low Heat (30-60degC) |

| Quality of Herbs | Can lose aroma and color | Better aroma and color retention |

| Moisture Removal | Surface moisture mainly | Deep moisture extraction |

| Energy Efficiency | Higher energy consumption | Lower energy consumption |

| Cost | Lower initial cost | Higher initial cost |

| Best For | Quick small batch drying | Large batch, high-quality drying |

Introduction to Herb Dehydration Techniques

Microwave drying rapidly removes moisture from herbs by using electromagnetic waves, preserving flavor and color more efficiently than traditional methods. Vacuum dehydrators operate under low pressure and temperature, minimizing nutrient loss and maintaining herb quality during the dehydration process.

Microwave drying suits small batches and quick processing, making it ideal for home use or quick preservation needs. Vacuum dehydrators require longer drying times but excel in retaining volatile oils and delicate textures in herbs like basil, thyme, and mint. Selecting between these methods depends on the desired quality, batch size, and specific herb characteristics.

Understanding Microwave Drying for Herbs

Microwave drying rapidly removes moisture from herbs by using electromagnetic waves, preserving flavor and color better than some traditional methods. This technique requires careful control of time and power settings to avoid overheating and loss of essential oils.

- Rapid Drying - Microwave drying significantly reduces dehydration time compared to conventional air drying.

- Flavor Preservation - The method effectively retains more aromatic compounds in herbs due to shorter exposure to heat.

- Risk of Overheating - Without precise control, microwave drying can damage delicate herb structures and degrade quality.

How Vacuum Dehydrators Work

Vacuum dehydrators remove moisture from herbs by lowering the pressure inside the drying chamber, which reduces the boiling point of water. This process allows herbs to dry at lower temperatures, preserving their essential oils and flavor compounds more effectively than microwave drying. The gentle vacuum environment prevents oxidation and degradation, ensuring higher quality and longer shelf life for dried herbs.

Speed: Which Method Dehydrates Herbs Faster?

| Microwave Drying Speed | Microwave drying dehydrates herbs significantly faster, often completing in 2-5 minutes due to rapid electromagnetic wave penetration that excites water molecules. |

| Vacuum Dehydrator Speed | Vacuum dehydrators take longer, typically 4-12 hours, as they gently remove moisture at low temperatures to preserve herb quality. |

| Speed Comparison | Microwave drying offers superior speed for quick dehydration but may sacrifice some flavor integrity, whereas vacuum dehydration prioritizes preservation with extended drying times. |

Flavor and Aroma Retention in Both Methods

Which method better preserves the flavor and aroma of herbs, microwave drying or vacuum dehydration? Vacuum dehydrators maintain herb quality by drying at lower temperatures and reducing oxidation, effectively retaining essential oils responsible for flavor and aroma. Microwave drying is faster but risks flavor loss due to uneven heating and volatile compound degradation.

Nutrient Preservation: Microwave vs. Vacuum

Microwave drying rapidly reduces moisture in herbs, preserving volatile oils and some heat-sensitive nutrients due to shorter exposure times. However, intense microwaves can degrade delicate compounds like flavonoids faster than gentler methods.

Vacuum dehydrators operate at lower temperatures with reduced oxygen, significantly enhancing nutrient retention, especially antioxidants and essential oils in herbs. This slow drying process maintains herb color, aroma, and potent phytochemicals, optimizing overall nutritional quality.

Texture and Color Differences

Microwave drying rapidly removes moisture from herbs, often preserving bright colors but resulting in a brittle texture. Vacuum dehydrators maintain a low-temperature environment, enhancing color retention while producing a more pliable and evenly dried herb. The choice between methods depends on whether texture flexibility or color vibrancy is the priority for the dried herbs.

Energy Efficiency and Cost Comparison

Microwave drying generally consumes less energy and reduces drying time compared to vacuum dehydrators, which require sustained power for maintaining low pressure. Cost-wise, vacuum dehydrators entail higher initial investment and operational expenses due to sophisticated components and maintenance needs.

- Energy Efficiency - Microwave drying uses rapid heat generation, lowering total energy consumption during herb dehydration.

- Cost of Equipment - Vacuum dehydrators typically have a higher upfront cost because of specialized vacuum pumps and airtight chambers.

- Operational Costs - Maintaining vacuum conditions increases electricity usage, resulting in greater long-term operational expenses.

Choosing between microwave drying and vacuum dehydration depends on balancing initial cost, energy consumption, and desired herb quality outcomes.

Usability and Convenience for Home Cooks

Microwave drying offers a quick and accessible method for home cooks, requiring only a standard microwave and minimal setup. However, it may result in uneven drying and a risk of overheating delicate herbs.

Vacuum dehydrators provide precise moisture control and preserve herb flavor and color effectively, though they tend to be bulkier and more expensive. Their user-friendly interfaces and consistent results make them ideal for enthusiasts committed to high-quality herb preservation.

Related Important Terms

Uniformity Index

Microwave drying offers rapid moisture removal but often results in a lower uniformity index compared to vacuum dehydrators, which provide more consistent heat distribution and maintain herb integrity. Vacuum dehydrators enhance uniformity by applying low pressure and controlled temperature, preserving essential oils and color while ensuring even dehydration throughout the herb material.

Microwave Absorption Efficiency

Microwave drying offers superior moisture removal for herbs due to its high microwave absorption efficiency, which rapidly heats water molecules inside plant cells, preserving aroma and active compounds. In contrast, vacuum dehydrators rely on low-pressure environments and lower temperatures but have slower drying times and less efficient energy absorption compared to microwave methods.

Low-Pressure Desorption

Microwave drying accelerates low-pressure desorption by rapidly heating herb moisture under controlled vacuum conditions, preserving essential oils and flavors more effectively than traditional vacuum dehydrators. Vacuum dehydrators rely on extended low-pressure exposure to gradually remove moisture, which can lead to longer drying times and potential loss of volatile compounds in heat-sensitive herbs.

Selective Volatile Retention

Microwave drying preserves selective volatile compounds in herbs more efficiently by rapidly heating and reducing exposure time, minimizing aroma loss compared to traditional methods. Vacuum dehydrators maintain volatile retention by drying under low pressure and temperature, preventing oxidation and preserving delicate flavor profiles essential for high-quality herbal products.

Dielectric Heating Profiles

Microwave drying leverages dielectric heating, causing rapid molecular vibration within herbs' water content, resulting in faster dehydration while preserving volatile oils. Vacuum dehydrators combine low pressure with controlled heat, reducing boiling points and minimizing thermal degradation, but dielectric heating in microwaves offers more uniform energy distribution and significantly shorter drying cycles for delicate herbs.

Aroma Loss Minimization

Microwave drying preserves herbal aroma more effectively by rapidly removing moisture at lower temperatures, reducing volatile oil degradation compared to vacuum dehydrators, which use prolonged low-pressure heat that can still cause subtle aroma loss. Selecting microwave drying optimizes retention of essential oils and aromatic compounds critical for maintaining herb quality and potency.

Phytochemical Preservation Ratio

Microwave drying rapidly removes moisture from herbs while preserving up to 75-85% of key phytochemicals like flavonoids and polyphenols, making it efficient for retaining antioxidant properties. Vacuum dehydrators operate at lower temperatures and reduced pressure, maintaining a higher phytochemical preservation ratio of approximately 90-95%, which better safeguards sensitive compounds such as essential oils and vitamins.

Microstructural Integrity Score

Microwave drying preserves microstructural integrity of herbs with a higher Microstructural Integrity Score by rapidly removing moisture while minimizing cell wall damage compared to conventional vacuum dehydrators. Vacuum dehydrators often cause more structural collapse due to prolonged dehydration times and lower drying rates, resulting in lower retention of cellular morphology and phytochemicals.

Pulsed Vacuum Technology

Microwave drying combined with pulsed vacuum technology accelerates moisture removal from herbs while preserving essential oils and nutrients by reducing oxidation and thermal degradation. Vacuum dehydrators utilizing pulsed vacuum cycles improve drying uniformity and efficiency, resulting in higher quality, aromatic, and shelf-stable herb products compared to conventional methods.

Microwave Drying vs Vacuum Dehydrator for Herbs Infographic

cookingdiff.com

cookingdiff.com