Traditional drying methods for jerky rely on airflow and heat to remove moisture, often resulting in longer drying times and uneven dehydration. Vacuum dehydrating uses low pressure to lower the boiling point of water, enabling faster drying at lower temperatures while preserving flavor and nutrients. This method produces tender jerky with consistent texture and reduces the risk of microbial growth compared to conventional drying.

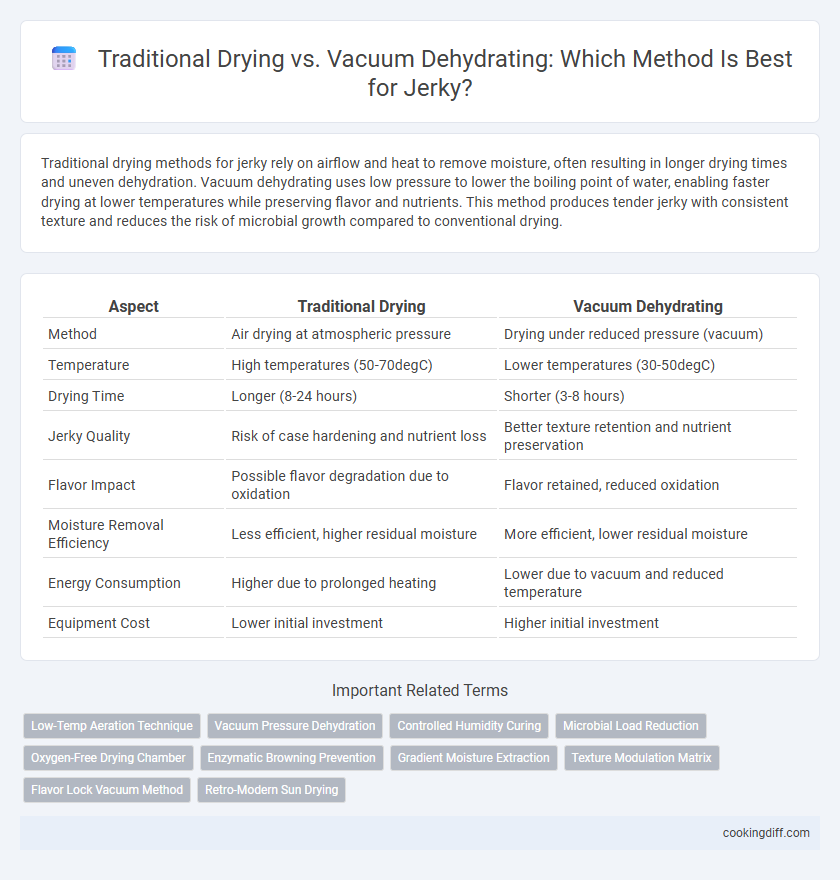

Table of Comparison

| Aspect | Traditional Drying | Vacuum Dehydrating |

|---|---|---|

| Method | Air drying at atmospheric pressure | Drying under reduced pressure (vacuum) |

| Temperature | High temperatures (50-70degC) | Lower temperatures (30-50degC) |

| Drying Time | Longer (8-24 hours) | Shorter (3-8 hours) |

| Jerky Quality | Risk of case hardening and nutrient loss | Better texture retention and nutrient preservation |

| Flavor Impact | Possible flavor degradation due to oxidation | Flavor retained, reduced oxidation |

| Moisture Removal Efficiency | Less efficient, higher residual moisture | More efficient, lower residual moisture |

| Energy Consumption | Higher due to prolonged heating | Lower due to vacuum and reduced temperature |

| Equipment Cost | Lower initial investment | Higher initial investment |

Introduction to Jerky Dehydration Methods

Dehydrating jerky preserves meat by removing moisture to prevent spoilage. Traditional drying and vacuum dehydrating represent two common approaches with differing effects on texture and shelf life.

- Traditional drying - uses ambient air and heat over several hours to slowly remove moisture from the meat.

- Vacuum dehydrating - reduces air pressure to lower the boiling point of water, drying jerky more quickly and evenly.

- Effect on quality - vacuum dehydration often results in better flavor retention and longer shelf stability compared to traditional methods.

What is Traditional Drying?

| Traditional drying involves using ambient air or low heat to remove moisture from jerky, often through sun drying or conventional dehydrators. This process relies on external factors such as temperature, humidity, and airflow to slowly evaporate water content, which can take several hours to days. Traditional drying may result in uneven dehydration and higher risk of bacterial growth compared to controlled methods like vacuum dehydrating. |

Understanding Vacuum Dehydrating

How does vacuum dehydrating improve the jerky drying process compared to traditional methods? Vacuum dehydrating removes moisture at lower temperatures by reducing air pressure, which helps retain the jerky's natural flavors and nutrients. This method also shortens drying time and minimizes oxidation, resulting in a higher-quality, shelf-stable product.

Flavor Differences: Traditional vs Vacuum-Dehydrated Jerky

Traditional drying techniques enhance jerky's flavor by slowly intensifying natural smoky and charred notes, resulting in a richer taste profile. Vacuum dehydrating preserves volatile aroma compounds better, maintaining the meat's original savory and spicy elements without oxidation. The contrast lies in traditional methods producing a robust, deep flavor while vacuum dehydration offers a fresher, cleaner taste experience.

Texture and Appearance Comparison

Traditional drying methods for jerky often result in a tougher, chewier texture with a darker, more uneven appearance due to prolonged exposure to air and heat. Vacuum dehydrating preserves a more tender texture and a uniform, vibrant color by removing moisture at lower temperatures and oxygen levels.

- Traditional drying texture - Jerky tends to be firmer and drier, sometimes leading to a leathery bite.

- Vacuum dehydrating texture - The process retains moisture more effectively, producing a softer, more pliable jerky.

- Appearance differences - Traditional drying can cause uneven color and surface cracks, while vacuum dehydration maintains a more consistent hue and smooth exterior.

Vacuum dehydrating enhances overall jerky quality by improving texture and appearance compared to traditional drying methods.

Nutrient Retention in Each Drying Method

Traditional drying methods for jerky, such as air drying or sun drying, often expose the meat to prolonged heat and oxygen, which can degrade heat-sensitive nutrients like vitamin B and antioxidants. This process typically results in lower retention of essential nutrients compared to more controlled drying techniques.

Vacuum dehydrating preserves nutrient content more effectively by removing air and reducing oxidation during drying, maintaining higher levels of vitamins and amino acids in the jerky. The low-oxygen environment also minimizes nutrient loss, leading to a more nutritionally dense final product.

Shelf Life and Storage Considerations

Traditional drying methods expose jerky to ambient air, increasing the risk of microbial contamination which can reduce shelf life to several weeks if not stored properly. Vacuum dehydrating removes air from the packaging, significantly extending shelf life by inhibiting oxidation and bacterial growth, often allowing jerky to last several months when stored in cool, dry conditions.

Proper storage of traditionally dried jerky requires airtight containers and cool environments to slow spoilage and maintain quality. Vacuum-sealed jerky benefits from minimal oxygen exposure, making it ideal for long-term storage without the need for refrigeration in many cases.

Energy Efficiency and Cost Analysis

Traditional drying methods for jerky consume significantly more energy due to prolonged exposure to heat and air circulation, leading to higher operational costs. Vacuum dehydrating uses lower temperatures and reduced pressure, enhancing energy efficiency and reducing electricity consumption.

Vacuum dehydration shortens drying time by accelerating moisture removal, which lowers overall energy usage and decreases production costs. Initial investment in vacuum dehydrators is higher, but long-term savings on energy bills and improved product quality offset this expense. Cost analysis reveals vacuum dehydrating as a more economically sustainable option for large-scale jerky production.

Safety and Food Preservation Factors

Vacuum dehydrating jerky significantly reduces oxidation and microbial growth by removing air, enhancing safety and extending shelf life more effectively than traditional drying methods. Traditional drying relies on heat and airflow, which can sometimes leave uneven moisture, increasing the risk of spoilage and foodborne pathogens.

- Vacuum Environment - Eliminates oxygen to slow bacterial growth and prevent rancidity.

- Consistent Moisture Removal - Ensures uniform dehydration to reduce spoilage risk.

- Lower Temperature Processing - Preserves nutrients and flavor while maintaining safety.

Related Important Terms

Low-Temp Aeration Technique

Vacuum dehydrating for jerky utilizes low-temp aeration techniques to preserve flavor and nutrients by removing moisture under reduced pressure at temperatures below 140degF. Traditional drying methods rely on higher heat and air circulation, often exceeding 150degF, which can degrade texture and diminish the jerky's nutritional value.

Vacuum Pressure Dehydration

Vacuum pressure dehydration for jerky removes moisture at lower temperatures by creating a reduced-pressure environment, preserving flavor, color, and nutritional value more effectively than traditional drying methods. This technique accelerates drying times while minimizing oxidation and microbial growth, resulting in a safer, higher-quality product with extended shelf life.

Controlled Humidity Curing

Traditional drying relies on ambient air and longer exposure times, which can lead to uneven moisture reduction and microbial risks during jerky preparation. Vacuum dehydrating employs controlled humidity curing, precisely regulating moisture levels to ensure consistent texture, enhanced flavor retention, and improved safety by minimizing bacterial growth.

Microbial Load Reduction

Traditional drying reduces microbial load through prolonged exposure to heat and air, but its efficacy can be limited by uneven drying and potential surface contamination. Vacuum dehydrating significantly enhances microbial load reduction by lowering oxygen levels and drying temperatures, which inhibits microbial growth and preserves jerky quality.

Oxygen-Free Drying Chamber

Vacuum dehydrating creates an oxygen-free drying chamber that reduces oxidation, preserves the jerky's color, and extends shelf life compared to traditional drying methods. This environment prevents microbial growth and nutrient loss by removing air, resulting in superior texture and flavor retention.

Enzymatic Browning Prevention

Vacuum dehydrating significantly reduces enzymatic browning in jerky by lowering oxygen exposure and temperature, which inhibits polyphenol oxidase activity responsible for discoloration. Traditional drying methods expose meat to higher oxygen levels and heat, increasing the risk of enzymatic browning and compromising the jerky's color and quality.

Gradient Moisture Extraction

Traditional drying methods for jerky rely on consistent heat and airflow to remove moisture, creating a gradual moisture gradient from the surface inward, which can result in uneven dehydration and prolonged drying times. Vacuum dehydrating enhances gradient moisture extraction by reducing atmospheric pressure, enabling faster moisture migration from the interior to the surface, ensuring uniform drying and improved texture retention in jerky products.

Texture Modulation Matrix

Traditional drying methods for jerky often result in uneven moisture distribution, leading to inconsistent texture characterized by a rigid outer layer and a tougher interior. Vacuum dehydrating utilizes low pressure to evenly remove moisture, producing a more uniform Texture Modulation Matrix that enhances chewiness and tenderness in the final product.

Flavor Lock Vacuum Method

Vacuum dehydrating jerky preserves natural flavors and nutrients by removing moisture at low pressure and temperature, preventing oxidative damage that traditional drying methods often cause. The Flavor Lock vacuum method enhances taste intensity and texture retention by sealing in aromas and reducing drying time significantly.

Traditional Drying vs Vacuum Dehydrating for jerky. Infographic

cookingdiff.com

cookingdiff.com