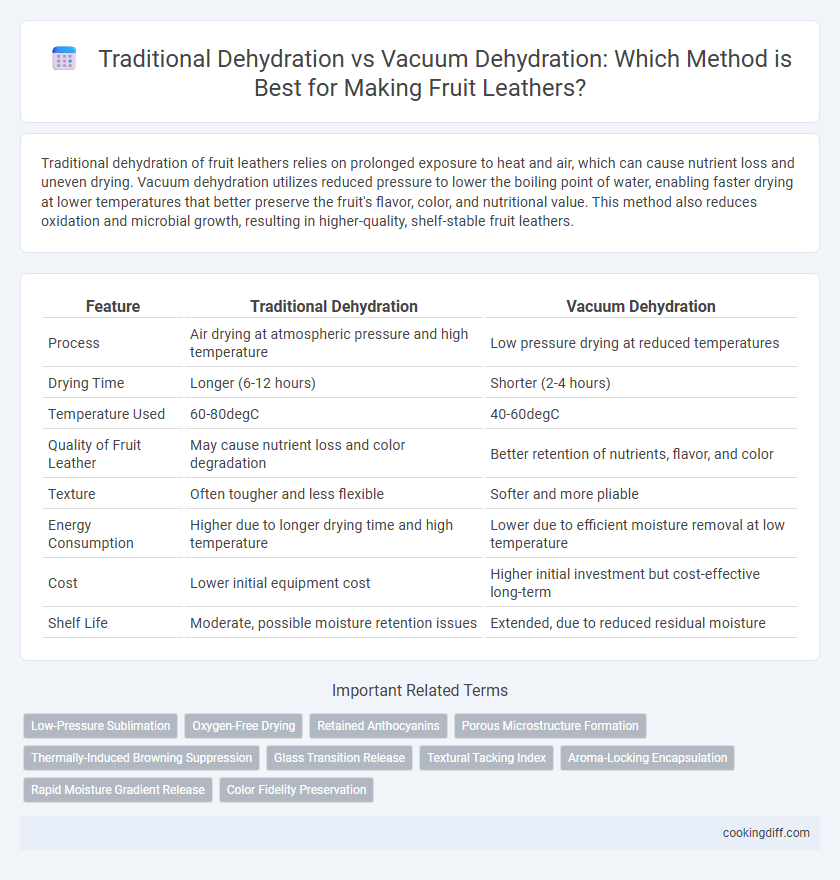

Traditional dehydration of fruit leathers relies on prolonged exposure to heat and air, which can cause nutrient loss and uneven drying. Vacuum dehydration utilizes reduced pressure to lower the boiling point of water, enabling faster drying at lower temperatures that better preserve the fruit's flavor, color, and nutritional value. This method also reduces oxidation and microbial growth, resulting in higher-quality, shelf-stable fruit leathers.

Table of Comparison

| Feature | Traditional Dehydration | Vacuum Dehydration |

|---|---|---|

| Process | Air drying at atmospheric pressure and high temperature | Low pressure drying at reduced temperatures |

| Drying Time | Longer (6-12 hours) | Shorter (2-4 hours) |

| Temperature Used | 60-80degC | 40-60degC |

| Quality of Fruit Leather | May cause nutrient loss and color degradation | Better retention of nutrients, flavor, and color |

| Texture | Often tougher and less flexible | Softer and more pliable |

| Energy Consumption | Higher due to longer drying time and high temperature | Lower due to efficient moisture removal at low temperature |

| Cost | Lower initial equipment cost | Higher initial investment but cost-effective long-term |

| Shelf Life | Moderate, possible moisture retention issues | Extended, due to reduced residual moisture |

Introduction to Fruit Leather Dehydration

Fruit leather dehydration transforms pureed fruits into a shelf-stable, chewy snack by removing moisture. Traditional dehydration uses ambient air circulation and heat, while vacuum dehydration operates under reduced pressure to lower drying temperature.

- Traditional Dehydration - employs hot air to evaporate moisture, which may alter color and nutrients due to higher temperatures.

- Vacuum Dehydration - dries fruit leather at lower temperatures under vacuum, preserving more flavor and nutritional content.

- Efficiency and Quality - vacuum dehydration typically results in faster drying with enhanced product texture and extended shelf life.

Choosing the appropriate dehydration method affects the sensory and nutritional qualities of fruit leather significantly.

Overview of Traditional Dehydration Methods

Traditional dehydration methods for fruit leathers primarily involve air drying or sun drying, where fruits are exposed to natural heat and airflow to remove moisture. These processes rely on temperature, humidity, and time to achieve the desired dryness and texture.

Sun drying is a cost-effective technique often used in regions with abundant sunlight, but it requires long drying periods and is susceptible to environmental contaminants. Air drying uses heated air circulation to speed up moisture removal and offers more control over drying conditions compared to sun drying. Both methods may result in uneven drying and nutrient loss due to prolonged exposure to heat and oxygen.

What is Vacuum Dehydration?

Vacuum dehydration removes moisture from fruit leathers at low pressure and temperature, preserving flavor and nutrients more effectively than traditional methods. This process reduces oxidation and prevents heat damage, resulting in a higher quality product with longer shelf life.

- Low Pressure Environment - Moisture evaporates under reduced pressure, allowing dehydration at lower temperatures.

- Enhanced Nutrient Retention - Lower temperature drying helps maintain vitamins and antioxidants in fruit leathers.

- Improved Texture and Flavor - Vacuum dehydration minimizes oxidation and heat degradation, preserving natural taste and texture.

Key Differences Between Traditional and Vacuum Dehydration

Traditional dehydration uses heat and air circulation to remove moisture, often resulting in longer drying times and potential nutrient loss in fruit leathers. Vacuum dehydration operates under reduced pressure, enabling faster moisture removal at lower temperatures, which better preserves flavor and nutrients.

- Drying Time - Vacuum dehydration significantly reduces drying time compared to the slower traditional method.

- Temperature Sensitivity - Vacuum dehydration uses lower temperatures, minimizing heat damage to fruit leather's vitamins and antioxidants.

- Product Quality - Fruit leathers dehydrated under vacuum retain better color, texture, and nutritional content than those dried traditionally.

Nutrient Retention: Traditional vs Vacuum Methods

| Dehydration Method | Nutrient Retention |

|---|---|

| Traditional Dehydration | Involves high heat and prolonged exposure to air, which can degrade sensitive nutrients such as vitamin C and antioxidants in fruit leathers. Nutrient loss tends to be more significant due to oxidation and thermal breakdown. |

| Vacuum Dehydration | Utilizes lower temperatures and reduced oxygen levels, significantly preserving heat-sensitive vitamins and phytochemicals. This method enhances retention of nutrients like vitamin A, vitamin C, and polyphenols in fruit leathers. |

Texture and Flavor: Impact on Fruit Leathers

Traditional dehydration exposes fruit leathers to prolonged heat and air, often resulting in a tougher texture and concentrated, sometimes caramelized flavors. This method can lead to uneven moisture removal, affecting the chewiness and overall mouthfeel of the final product.

Vacuum dehydration operates at lower temperatures under reduced pressure, preserving the delicate texture and bright, fresh fruit flavors in fruit leathers. This process minimizes oxidation and heat damage, maintaining a softer, more pliable texture and vibrant taste profile.

Energy Efficiency and Time Comparison

Traditional dehydration of fruit leathers consumes significantly more energy due to prolonged heating times, often lasting 8 to 12 hours at temperatures around 60-70degC. Vacuum dehydration reduces drying time by 30-50%, operating at lower temperatures of 40-50degC, which enhances energy efficiency by minimizing thermal degradation and power usage. The accelerated process not only preserves nutrient content but also decreases production costs, making vacuum dehydration a superior method for sustainable fruit leather processing.

Equipment Requirements and Accessibility

Traditional dehydration of fruit leathers requires basic equipment such as an oven or food dehydrator, which are widely accessible and cost-effective for home use. Vacuum dehydration demands specialized vacuum chambers and pumps, making the equipment more complex and expensive, often limiting its use to commercial or industrial settings. Accessibility to vacuum dehydration technology is lower due to its higher initial investment and maintenance requirements compared to traditional methods.

Cost Implications of Each Dehydration Method

Traditional dehydration methods for fruit leathers often involve lower initial equipment costs but higher energy consumption over time, increasing operational expenses. These methods typically rely on ambient air drying, which can extend processing times and impact overall efficiency.

Vacuum dehydration requires a higher upfront investment due to specialized machinery but offers significant energy savings and faster drying times. The vacuum environment reduces oxidation and preserves nutrients, potentially lowering quality loss costs and increasing product value.

Related Important Terms

Low-Pressure Sublimation

Traditional dehydration of fruit leathers relies on air-drying at atmospheric pressure, often resulting in longer drying times and potential quality degradation, while vacuum dehydration utilizes low-pressure sublimation to efficiently remove moisture by turning ice directly into vapor, preserving flavor and nutrients. Low-pressure sublimation in vacuum dehydration reduces oxidation and heat damage, producing fruit leathers with superior texture, color retention, and shelf life compared to conventional methods.

Oxygen-Free Drying

Traditional dehydration exposes fruit leathers to oxygen-rich heat, increasing oxidation risk and nutrient loss, while vacuum dehydration removes oxygen through low-pressure conditions, preserving color, flavor, and vitamins by preventing oxidative damage. Oxygen-free drying in vacuum dehydration enhances shelf life and maintains the nutritional integrity of fruit leathers more effectively than conventional methods.

Retained Anthocyanins

Vacuum dehydration preserves a higher concentration of anthocyanins in fruit leathers compared to traditional dehydration methods due to reduced oxygen exposure and lower drying temperatures. This advanced technique minimizes pigment degradation, enhancing antioxidant retention and overall nutritional quality.

Porous Microstructure Formation

Traditional dehydration creates a porous microstructure in fruit leathers through gradual moisture removal at atmospheric pressure, often resulting in uneven texture and longer drying times. Vacuum dehydration accelerates drying by lowering the boiling point of water, producing a more uniform and finer porous structure that enhances rehydration and texture quality.

Thermally-Induced Browning Suppression

Vacuum dehydration significantly reduces thermally-induced browning in fruit leathers by lowering the boiling point of water, thereby enabling drying at lower temperatures compared to traditional dehydration methods. This temperature control preserves the natural color and flavor compounds, enhancing the visual and sensory quality of the final product.

Glass Transition Release

Traditional dehydration of fruit leathers often results in inconsistent moisture removal and increased risk of glass transition release, leading to stickiness and quality loss. Vacuum dehydration reduces the glass transition temperature by removing moisture at lower pressures, preserving the texture and enhancing shelf life.

Textural Tacking Index

Vacuum dehydration significantly improves the Textural Tacking Index of fruit leathers by reducing moisture content uniformly and preserving the product's pliability and chewiness. Traditional dehydration often results in uneven drying, causing inconsistent texture and higher surface stickiness compared to the smoother, more stable texture achieved through vacuum methods.

Aroma-Locking Encapsulation

Traditional dehydration often results in significant aroma loss due to prolonged exposure to heat and oxygen, compromising the flavor profile of fruit leathers, whereas vacuum dehydration employs Aroma-Locking Encapsulation technology to preserve volatile compounds by reducing oxidative degradation and maintaining vibrant, fresh fruit aromas. This method enhances the sensory quality and shelf-life of fruit leathers by encapsulating aromatic molecules within a controlled low-pressure environment, ensuring maximum flavor retention.

Rapid Moisture Gradient Release

Traditional dehydration of fruit leathers relies on high temperature and prolonged exposure to air, causing a slow moisture gradient release that can degrade flavor and texture. Vacuum dehydration accelerates moisture removal by reducing pressure, enabling rapid moisture gradient release at lower temperatures, preserving nutrients and enhancing the fruit leather's quality.

Traditional dehydration vs Vacuum dehydration for fruit leathers. Infographic

cookingdiff.com

cookingdiff.com