Sun drying fruit chips relies on natural heat and air circulation but can be inconsistent due to weather variability and longer drying times, potentially leading to uneven dehydration and spoilage. Excalibur dehydrators provide controlled temperature and airflow, ensuring uniform drying and preserving flavor, texture, and nutrients more effectively. Choosing an Excalibur dehydrator offers a reliable and efficient method for producing high-quality fruit chips compared to traditional sun drying.

Table of Comparison

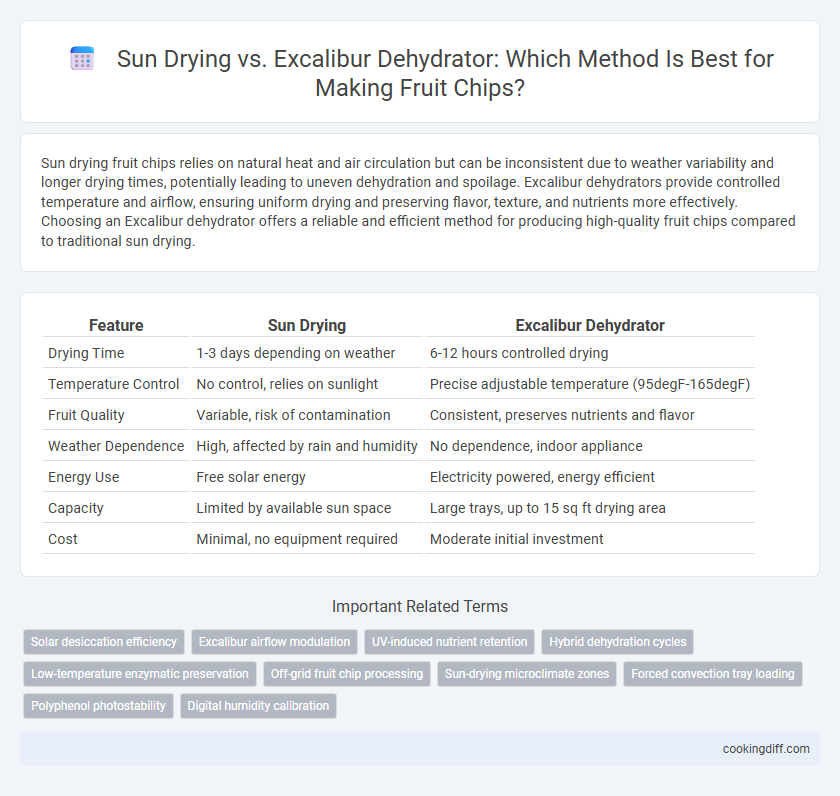

| Feature | Sun Drying | Excalibur Dehydrator |

|---|---|---|

| Drying Time | 1-3 days depending on weather | 6-12 hours controlled drying |

| Temperature Control | No control, relies on sunlight | Precise adjustable temperature (95degF-165degF) |

| Fruit Quality | Variable, risk of contamination | Consistent, preserves nutrients and flavor |

| Weather Dependence | High, affected by rain and humidity | No dependence, indoor appliance |

| Energy Use | Free solar energy | Electricity powered, energy efficient |

| Capacity | Limited by available sun space | Large trays, up to 15 sq ft drying area |

| Cost | Minimal, no equipment required | Moderate initial investment |

Introduction to Fruit Chip Dehydration Methods

Sun drying and using an Excalibur dehydrator are two primary methods for making fruit chips, each with distinct benefits and limitations. Understanding their differences helps optimize dehydration results based on climate, time, and quality preferences.

- Sun drying - Utilizes natural sunlight and airflow, requiring warm, dry weather for effective fruit dehydration.

- Excalibur dehydrator - Provides controlled temperature and airflow settings, ensuring consistent drying regardless of external conditions.

- Energy efficiency - Sun drying is energy-free but weather-dependent, while Excalibur dehydrators use electricity for reliable performance.

Choosing the ideal dehydration method depends on balancing convenience, drying speed, and final fruit chip texture.

Overview of Sun Drying for Fruit Chips

Sun drying is a traditional method of dehydrating fruit chips that relies on natural sunlight and ambient temperature. This process can take several days, depending on weather conditions and fruit thickness.

- Low Cost - Sun drying requires minimal equipment, making it an economical choice for dehydration.

- Variable Drying Time - The duration depends on sunlight intensity, humidity, and air circulation.

- Quality Considerations - Exposure to dust and pests can affect the cleanliness and uniformity of dried fruit chips.

Introduction to Excalibur Dehydrator Technology

The Excalibur dehydrator uses advanced airflow technology ensuring consistent low-temperature drying, preserving the natural flavors and nutrients of fruit chips better than traditional sun drying. Unlike sun drying, which relies on unpredictable weather and risks contamination, the Excalibur offers precise temperature control and extended drying periods for uniform results. Its airtight environment and adjustable trays significantly reduce oxidation and spoilage, making it a superior choice for quality fruit chip production.

Comparative Drying Times: Sun vs Excalibur

Sun drying fruit chips can take several days depending on weather conditions, while the Excalibur dehydrator typically completes the process within 6 to 12 hours. Controlled heat and airflow in the Excalibur ensure consistent drying times compared to the variability of sun exposure.

- Sun drying requires extended time - Fruit chips may need 2 to 4 days to dehydrate fully under optimal sun conditions.

- Excalibur provides faster drying - The dehydrator uses regulated temperature and airflow to dry fruit chips swiftly in about half a day.

- Weather dependency affects sun drying - Cloud cover, humidity, and temperature fluctuations can delay sun drying significantly.

Nutrient Retention: Sun Drying vs Mechanical Dehydration

Sun drying fruit chips exposes them to fluctuating temperatures and direct sunlight, which can degrade heat-sensitive vitamins such as vitamin C and certain antioxidants. The Excalibur dehydrator uses controlled low heat and consistent airflow, preserving higher levels of nutrients and maintaining better color and flavor. Studies indicate mechanical dehydration with Excalibur retains up to 25% more nutrients compared to traditional sun drying methods.

Flavor and Texture Differences in Fruit Chips

Sun drying imparts a natural, slightly caramelized flavor to fruit chips due to slow evaporation and mild heat exposure, resulting in a chewier texture with some variability depending on weather conditions. The Excalibur dehydrator offers precise temperature control, preserving vibrant fruit flavors and producing consistently crisp and evenly dried chips.

Sun drying often leads to uneven moisture removal, which can cause some fruit chips to be softer or tougher than others, whereas the Excalibur's controlled airflow prevents this inconsistency. The dehydrator enhances flavor retention by reducing enzymatic browning and oxidation common in open-air drying. Overall, fruit chips dried with an Excalibur maintain superior texture and flavor uniformity compared to the variable results of sun drying.

Energy Efficiency and Environmental Impact

| Method | Energy Efficiency | Environmental Impact |

|---|---|---|

| Sun Drying | Zero energy consumption; relies entirely on solar power, making it the most energy-efficient method. | Minimal environmental footprint; no emissions or electricity use, but dependent on weather conditions and longer drying times. |

| Excalibur Dehydrator | Uses electricity with energy-efficient heating elements and fan system; consumes approximately 600 watts per hour. | Moderate environmental impact due to electricity use; faster drying reduces potential spoilage and waste, but energy source affects carbon footprint. |

Suitability for Different Climates and Regions

Sun drying fruit chips is most suitable in hot, dry climates with low humidity, where ample sunlight and consistent temperatures can efficiently remove moisture without spoilage. Regions with high humidity or frequent rain face challenges using sun drying, as moisture retention increases the risk of mold and uneven drying.

Excalibur dehydrators provide controlled temperature and airflow, making them ideal for various climates, including humid and cold regions where sun drying is impractical. Their adjustable settings ensure consistent dehydration results regardless of external weather conditions, enhancing fruit chip quality and shelf life.

Cost-Effectiveness: Initial and Ongoing Expenses

Which method offers better cost-effectiveness for making fruit chips: sun drying or using an Excalibur dehydrator? Sun drying involves minimal initial investment but depends heavily on weather and can result in inconsistent quality. The Excalibur dehydrator requires a higher upfront cost and electricity expenses but provides reliable, uniform dehydration and faster processing times.

Related Important Terms

Solar desiccation efficiency

Sun drying fruit chips relies on solar desiccation, harnessing natural sunlight and ambient air, but often suffers from inconsistent temperatures and exposure to contaminants, leading to longer drying times and variable quality. The Excalibur dehydrator offers controlled, uniform heat distribution and airflow, significantly improving drying efficiency and product safety compared to traditional solar drying methods.

Excalibur airflow modulation

Excalibur dehydrators offer precise airflow modulation that enhances drying consistency and preserves nutrients in fruit chips, unlike sun drying which depends on unpredictable weather conditions and can lead to uneven moisture removal. Controlled temperature and airflow in Excalibur units ensure faster dehydration and superior texture compared to the prolonged, less reliable process of sun drying.

UV-induced nutrient retention

Sun drying fruit chips exposes them to ultraviolet (UV) radiation, which can degrade sensitive nutrients such as vitamin C and polyphenols, reducing their nutritional value. The Excalibur dehydrator controls temperature and airflow without UV exposure, preserving higher levels of antioxidants and essential vitamins in fruit chips.

Hybrid dehydration cycles

Hybrid dehydration cycles combine the natural sunlight exposure of sun drying with the controlled temperature and airflow of an Excalibur dehydrator, optimizing moisture removal for fruit chips. This method enhances flavor retention and nutritional value while reducing drying time and minimizing the risk of bacterial contamination compared to traditional drying techniques.

Low-temperature enzymatic preservation

Sun drying fruit chips exposes them to fluctuating temperatures and oxygen, which can degrade enzymes and nutrients, whereas the Excalibur dehydrator maintains consistent low temperatures around 125degF, ensuring optimal enzymatic preservation. This controlled environment reduces oxidation and enzymatic breakdown, resulting in higher nutrient retention and better texture in fruit chips.

Off-grid fruit chip processing

Sun drying fruit chips off-grid leverages natural solar energy for cost-effective dehydration but requires ideal weather conditions and extended drying times that can impact yield and quality. Excalibur dehydrators provide consistent temperature control and faster drying cycles, optimizing texture and flavor preservation in remote locations without reliable electricity access by using solar-compatible power sources.

Sun-drying microclimate zones

Sun drying fruit chips is highly dependent on microclimate zones with low humidity, consistent sunlight, and temperatures between 85degF to 110degF for effective dehydration and food safety. Excalibur dehydrators provide controlled temperature settings, airflow, and protection from contaminants, ensuring uniform drying regardless of regional climate variability.

Forced convection tray loading

Sun drying fruit chips relies on natural convection and uneven heat distribution, resulting in inconsistent moisture removal and longer dehydration times. The Excalibur dehydrator uses forced convection with uniform tray loading, ensuring consistent airflow and temperature control for faster, evenly dried fruit chips with enhanced texture and flavor preservation.

Polyphenol photostability

Sun drying of fruit chips often leads to significant degradation of polyphenols due to prolonged exposure to ultraviolet light, causing reduced antioxidant capacity. The Excalibur dehydrator, with its controlled temperature and absence of direct light, better preserves polyphenol photostability, maintaining nutritional quality and enhancing shelf life.

Sun drying vs Excalibur dehydrator for fruit chips Infographic

cookingdiff.com

cookingdiff.com