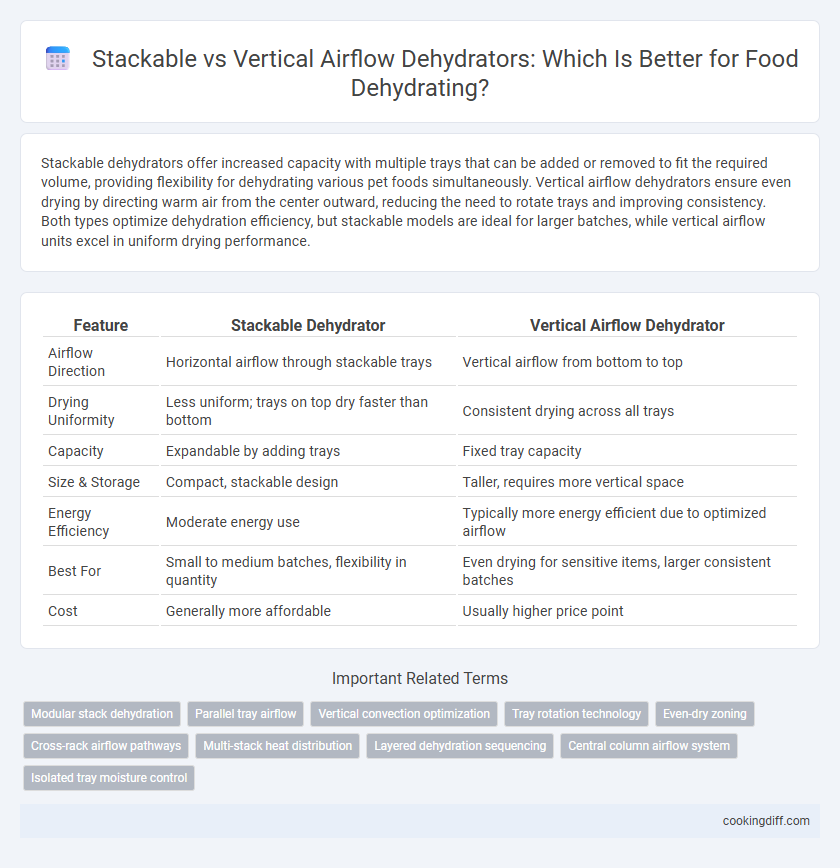

Stackable dehydrators offer increased capacity with multiple trays that can be added or removed to fit the required volume, providing flexibility for dehydrating various pet foods simultaneously. Vertical airflow dehydrators ensure even drying by directing warm air from the center outward, reducing the need to rotate trays and improving consistency. Both types optimize dehydration efficiency, but stackable models are ideal for larger batches, while vertical airflow units excel in uniform drying performance.

Table of Comparison

| Feature | Stackable Dehydrator | Vertical Airflow Dehydrator |

|---|---|---|

| Airflow Direction | Horizontal airflow through stackable trays | Vertical airflow from bottom to top |

| Drying Uniformity | Less uniform; trays on top dry faster than bottom | Consistent drying across all trays |

| Capacity | Expandable by adding trays | Fixed tray capacity |

| Size & Storage | Compact, stackable design | Taller, requires more vertical space |

| Energy Efficiency | Moderate energy use | Typically more energy efficient due to optimized airflow |

| Best For | Small to medium batches, flexibility in quantity | Even drying for sensitive items, larger consistent batches |

| Cost | Generally more affordable | Usually higher price point |

Overview of Stackable and Vertical Airflow Dehydrators

What are the main differences between stackable dehydrators and vertical airflow dehydrators in food dehydration? Stackable dehydrators use multiple trays stacked vertically, allowing airflow to pass evenly through each tray, making them suitable for small batches and varied drying needs. Vertical airflow dehydrators direct air from the bottom upward, providing consistent drying with greater efficiency for larger quantities and uniform moisture removal.

Key Differences in Design and Structure

Stackable dehydrators feature trays stacked vertically, allowing heat to rise naturally through each layer. Vertical airflow dehydrators use a centralized fan that distributes air evenly through all trays, preventing uneven drying.

- Design Orientation - Stackable models rely on vertical heat flow while vertical airflow models use a side-mounted fan to circulate air.

- Air Distribution - Vertical airflow dehydrators ensure consistent temperature and airflow across all trays, reducing drying time.

- Space Efficiency - Stackable dehydrators allow adding or removing trays to adjust capacity, whereas vertical airflow units have fixed tray structures.

Airflow Technology: Stacking vs Vertical Systems

| Stackable Dehydrator | Utilizes horizontal airflow through stacked trays, ensuring even drying but may require rotation for uniform dehydration. Air moves laterally, promoting consistent moisture removal across layers when trays are properly spaced. |

| Vertical Airflow Dehydrator | Features vertical airflow passing through all trays simultaneously, enhancing drying speed and uniformity without manual rotation. This system optimizes air distribution and reduces drying time by delivering heated air from bottom to top. |

Evenness of Drying Performance Compared

Stackable dehydrators utilize individual trays that allow users to customize the quantity and arrangement, but airflow may be uneven, causing inconsistent drying across layers. Vertical airflow dehydrators feature a centralized fan that distributes air uniformly, ensuring consistent dehydration on all trays simultaneously.

Vertical airflow technology typically delivers faster and more reliable drying results due to even heat and air distribution. Stackable designs may require tray rotation to achieve uniform dryness, which can be labor-intensive and less efficient for large batches.

Capacity and Scalability for Home Use

Stackable dehydrators offer modular capacity, allowing users to add or remove trays based on the volume of food being dried, which is ideal for variable batch sizes in home kitchens. Vertical airflow dehydrators provide consistent drying with a fixed capacity, typically accommodating smaller to medium quantities efficiently within a compact footprint.

For home use, stackable models excel in scalability, enabling gradual expansion without replacing the entire unit, making them versatile for growing dehydration needs. Vertical airflow dehydrators maintain uniform heat distribution, reducing drying time for smaller loads while conserving counter space. Both types cater to different capacity demands, but stackable dehydrators provide greater flexibility for fluctuating food volumes.

Energy Efficiency and Drying Times

Stackable dehydrators often consume more energy due to their horizontal heating elements but allow for larger batch sizes reducing overall drying cycles. Vertical airflow dehydrators typically offer faster drying times with lower energy usage by evenly distributing heat through a vertical fan system.

- Energy Consumption - Stackable models generally use more power per hour compared to vertical airflow units.

- Drying Efficiency - Vertical airflow systems provide consistent heat circulation, cutting drying times significantly.

- Batch Capacity - Stackable dehydrators enable drying multiple trays simultaneously, optimizing larger food volumes.

Ease of Use and Maintenance

Stackable dehydrators offer modular trays that can be added or removed easily, simplifying cleaning and customization of drying capacity. Vertical airflow dehydrators use a fan-driven system that ensures even drying but can require more frequent maintenance due to parts like fans and vents. Users seeking straightforward tray access and minimal upkeep typically prefer stackable designs.

Versatility and Types of Foods Dehydrated

Stackable dehydrators offer versatility by allowing users to adjust the number of trays based on the quantity of food, making them ideal for drying a variety of items such as fruits, vegetables, and herbs in different batch sizes. Their horizontal airflow system ensures even drying, which is beneficial for thicker or denser foods that require consistent heat distribution.

Vertical airflow dehydrators provide efficient drying through a single heating element and fan at the base, offering uniform air circulation that excels with lightweight or thinly sliced foods like jerky, fruits, and herbs. They tend to be more compact and energy-efficient, but may struggle with large or bulky items due to less customizable space compared to stackable models.

Noise Levels and Space Requirements

Stackable dehydrators typically generate higher noise levels due to multiple fans operating simultaneously, making them less suitable for quiet environments. Vertical airflow dehydrators operate with a single fan, producing significantly lower noise and creating a more peaceful dehydration process. In terms of space, stackable models require a larger footprint with expandable trays, while vertical airflow dehydrators maintain a compact, vertical design ideal for small kitchens and limited counter space.

Related Important Terms

Modular stack dehydration

Modular stack dehydrators offer customizable capacity by allowing users to add or remove trays to accommodate varying dehydration volumes, making them ideal for efficient batch drying of fruits, vegetables, and herbs. Vertical airflow dehydrators ensure even drying by circulating hot air uniformly through stacked trays, reducing drying time and preserving nutrient content during the dehydration process.

Parallel tray airflow

Stackable dehydrators utilize parallel tray airflow, where air moves horizontally across each tray, ensuring uniform drying of food items with consistent temperature distribution. Vertical airflow dehydrators, by contrast, push air from bottom to top, which may cause uneven dehydration due to heat rising and varying airflow intensity on different trays.

Vertical convection optimization

Vertical airflow dehydrators optimize dehydration by circulating hot air evenly through multiple trays, ensuring faster and more uniform drying compared to stackable dehydrators where airflow can be obstructed between layers. This vertical convection minimizes moisture retention, reduces drying time, and preserves nutrients and flavor more effectively.

Tray rotation technology

Stackable dehydrators utilize tray rotation technology that evenly exposes food to heat and airflow by mechanically turning trays, ensuring uniform dehydration and preventing hotspots. Vertical airflow dehydrators rely on consistent airflow from bottom to top but lack tray rotation, which can result in uneven drying and require manual tray rearrangement for optimal results.

Even-dry zoning

Stackable dehydrators provide more even-dry zoning by allowing airflow to be distributed horizontally across each tray, minimizing differences in moisture levels between layers. Vertical airflow dehydrators rely on air moving from bottom to top, which can create uneven drying zones as trays at different heights receive varying air exposure.

Cross-rack airflow pathways

Stackable dehydrators feature cross-rack airflow pathways that allow air to pass horizontally through each tray, ensuring even drying across all layers by preventing moisture buildup. Vertical airflow dehydrators channel air from bottom to top, but may have less efficient cross-rack circulation, potentially causing uneven dehydration on certain trays.

Multi-stack heat distribution

Stackable dehydrators provide multi-stack heat distribution by allowing trays to be added and heated simultaneously, ensuring even drying across all layers with consistent temperature control. Vertical airflow dehydrators use a bottom-to-top air circulation system that promotes uniform moisture removal, but may struggle with heat consistency on higher stacks compared to stackable models.

Layered dehydration sequencing

Stackable dehydrators enable precise layered dehydration sequencing by allowing users to add or remove trays, optimizing airflow for uniform drying of different food types simultaneously. Vertical airflow dehydrators offer consistent heat circulation through each layer, minimizing cross-contamination and ensuring even dehydration across stacked trays.

Central column airflow system

Stackable dehydrators utilize a central column airflow system that evenly distributes hot air from the middle, ensuring consistent dehydration across all trays, which reduces drying times and prevents uneven moisture retention. In contrast, vertical airflow dehydrators push air from the rear or bottom, potentially causing less uniform drying and requiring more frequent tray rotation to achieve similar results.

Stackable dehydrator vs Vertical airflow dehydrator for dehydrating. Infographic

cookingdiff.com

cookingdiff.com