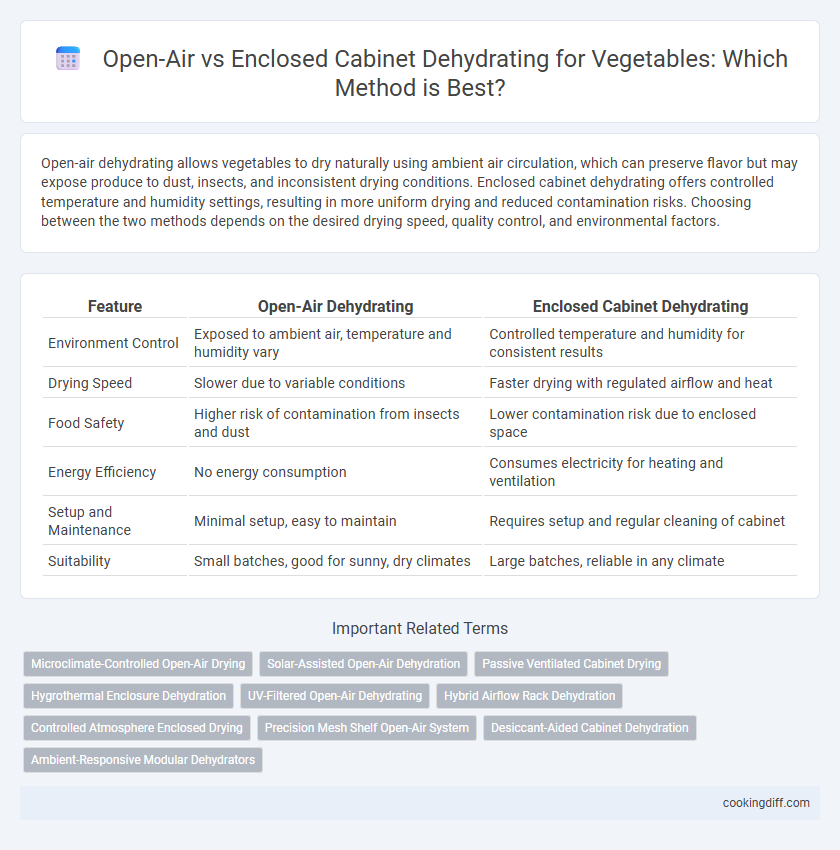

Open-air dehydrating allows vegetables to dry naturally using ambient air circulation, which can preserve flavor but may expose produce to dust, insects, and inconsistent drying conditions. Enclosed cabinet dehydrating offers controlled temperature and humidity settings, resulting in more uniform drying and reduced contamination risks. Choosing between the two methods depends on the desired drying speed, quality control, and environmental factors.

Table of Comparison

| Feature | Open-Air Dehydrating | Enclosed Cabinet Dehydrating |

|---|---|---|

| Environment Control | Exposed to ambient air, temperature and humidity vary | Controlled temperature and humidity for consistent results |

| Drying Speed | Slower due to variable conditions | Faster drying with regulated airflow and heat |

| Food Safety | Higher risk of contamination from insects and dust | Lower contamination risk due to enclosed space |

| Energy Efficiency | No energy consumption | Consumes electricity for heating and ventilation |

| Setup and Maintenance | Minimal setup, easy to maintain | Requires setup and regular cleaning of cabinet |

| Suitability | Small batches, good for sunny, dry climates | Large batches, reliable in any climate |

Introduction to Vegetable Dehydrating Methods

| Open-air dehydrating exposes vegetables to natural sunlight and ambient air, promoting slow moisture removal that enhances flavor retention but requires favorable weather conditions and longer drying times. |

| Enclosed cabinet dehydrating utilizes controlled temperature and airflow within a sealed environment, allowing consistent drying regardless of external weather, reducing spoilage risk and improving nutrient preservation. |

| Choosing between these methods depends on factors such as desired drying speed, climate, and the specific vegetable's moisture content, impacting texture and shelf life outcomes. |

What Is Open-Air Dehydrating?

Open-air dehydrating involves drying vegetables by exposing them to natural air and sunlight, leveraging ambient conditions for moisture removal. This method is energy-efficient and cost-effective but depends heavily on weather, requiring low humidity and consistent temperatures for optimal results. Unlike enclosed cabinet dehydrators, open-air techniques may expose produce to contaminants, necessitating protective measures during the drying process.

Understanding Enclosed Cabinet Dehydrating

Enclosed cabinet dehydrating for vegetables maintains consistent temperature and airflow, ensuring even moisture removal and reducing the risk of contamination. This method allows precise control over drying conditions, which helps preserve nutrients and color better than open-air dehydrating. Enclosed cabinets are especially effective for high-moisture vegetables, providing uniform dehydration without exposure to pests or dust.

Climate and Weather Impact on Dehydrating Techniques

How does climate influence the choice between open-air and enclosed cabinet dehydrating for vegetables? Open-air dehydrating depends heavily on dry, warm weather to prevent mold and uneven drying, making it less effective in humid or rainy climates. Enclosed cabinet dehydrators control temperature and humidity, providing consistent drying results regardless of outdoor weather conditions.

Equipment and Setup Requirements Compared

Open-air dehydrating requires minimal equipment, often just racks or screens placed in a well-ventilated area, making it cost-effective but weather-dependent. Enclosed cabinet dehydrators use electric heating elements and fans housed in a sealed unit, providing consistent temperature and airflow control for reliable drying.

Open-air setups demand space with good air circulation and protection from pests or contaminants, limiting usage in humid or unpredictable climates. Enclosed cabinets require electricity and maintenance of internal components, but they optimize drying speed and preserve nutrient quality by maintaining stable conditions. Choice of method impacts the efficiency, quality, and scalability of vegetable dehydration processes.

Dehydrating Efficiency and Time Differences

Open-air dehydrating exposes vegetables to natural airflow and sunlight, resulting in longer drying times and less consistent moisture removal. Enclosed cabinet dehydrators use controlled heat and airflow to significantly improve dehydrating efficiency and reduce drying time.

- Open-air drying - Relies on ambient conditions, causing variable dehydration speed and potential contamination risks.

- Enclosed cabinet drying - Provides consistent temperature and airflow, ensuring uniform and faster dehydration.

- Time efficiency - Cabinet dehydrators typically reduce drying time by 50% or more compared to open-air methods.

Food Safety and Contamination Risks

Open-air dehydrating exposes vegetables to environmental contaminants such as dust, insects, and airborne bacteria, increasing the risk of foodborne illnesses. Lack of controlled temperature and humidity can lead to uneven drying, promoting microbial growth and spoilage.

Enclosed cabinet dehydrating offers a sanitized environment with regulated airflow and consistent heat, minimizing contamination and ensuring safer preservation. The closed system reduces exposure to external pathogens, significantly enhancing food safety during the dehydration process.

Flavor, Texture, and Nutrition Retention

Open-air dehydrating allows vegetables to dry naturally with ambient airflow, preserving more of their fresh, vibrant flavors but can lead to uneven texture due to variable humidity and temperature. This method may cause slight nutrient loss, particularly in sensitive vitamins like vitamin C, because of prolonged exposure to sunlight and oxygen.

Enclosed cabinet dehydrating uses controlled temperature and airflow to ensure consistent drying, enhancing texture uniformity and crispness while better retaining nutrients through reduced exposure to light and air. This method optimizes flavor concentration without over-drying, making it ideal for maintaining the nutritional quality and desirable taste of dehydrated vegetables.

Cost and Accessibility Considerations

Open-air dehydrating is a low-cost method relying on natural sunlight, making it highly accessible but weather-dependent, while enclosed cabinet dehydrating requires an initial investment in equipment yet offers consistent drying regardless of environmental conditions.

- Cost Efficiency - Open-air dehydrating has minimal upfront costs, whereas cabinet dehydrators range from $50 to $300 based on capacity and features.

- Accessibility - Open-air methods are suitable for regions with abundant sunlight, while enclosed cabinets can be used year-round in any climate.

- Energy Use - Open-air relies on free solar energy, whereas cabinet dehydrators require electricity, impacting operational costs.

Choosing between these methods depends on budget constraints and local climate conditions for optimal vegetable dehydration.

Related Important Terms

Microclimate-Controlled Open-Air Drying

Microclimate-controlled open-air dehydrating optimizes airflow and humidity levels around vegetables, preserving nutrients and flavor more effectively than traditional open-air drying. Unlike enclosed cabinet dehydrators, it reduces moisture buildup and prevents spoilage by maintaining a stable environment without relying on electric energy.

Solar-Assisted Open-Air Dehydration

Solar-assisted open-air dehydration leverages natural sunlight and ambient air to efficiently remove moisture from vegetables, preserving nutrients and flavor while reducing energy consumption compared to enclosed cabinet dehydrating systems. This eco-friendly method optimizes drying by maximizing airflow and UV exposure, which inhibits microbial growth and enhances shelf life without the need for electric power.

Passive Ventilated Cabinet Drying

Passive ventilated cabinet drying for vegetables leverages natural airflow through strategically placed vents, enhancing moisture evaporation without the need for mechanical fans or external power. This method maintains consistent temperature and humidity levels, preserving nutrient content and texture better than open-air dehydrating while reducing contamination risks.

Hygrothermal Enclosure Dehydration

Hygrothermal enclosure dehydration in enclosed cabinet dehydrators maintains precise humidity and temperature control, optimizing moisture removal from vegetables while preserving nutrients and texture. Open-air dehydration lacks this controlled environment, resulting in slower drying times and higher risk of contamination or uneven drying.

UV-Filtered Open-Air Dehydrating

UV-filtered open-air dehydrating preserves essential nutrients and vibrant colors in vegetables by minimizing exposure to harmful ultraviolet rays, unlike traditional open-air drying. This method enhances airflow and natural flavor retention while reducing microbial growth, offering a sustainable alternative to enclosed cabinet dehydrators that rely on controlled heat and limited ventilation.

Hybrid Airflow Rack Dehydration

Hybrid Airflow Rack Dehydration combines the efficiency of open-air dehydrating's natural ventilation with the controlled environment of enclosed cabinet systems, optimizing moisture removal for vegetables. This method enhances uniform drying and preserves nutrient content by balancing airflow, temperature, and humidity control.

Controlled Atmosphere Enclosed Drying

Controlled atmosphere enclosed cabinet dehydrators maintain optimal temperature and humidity levels, preserving nutritional content and enhancing the flavor of vegetables more effectively than open-air methods. This precise environment also reduces drying time and minimizes contamination risks, ensuring consistent quality in the final dehydrated products.

Precision Mesh Shelf Open-Air System

The Precision Mesh Shelf Open-Air System enhances open-air dehydrating for veggies by providing superior airflow and even drying, preventing moisture retention and spoilage. Unlike enclosed cabinet systems that may trap humidity, this design ensures efficient dehydration and maintains nutritional content by maximizing exposure to ambient air.

Desiccant-Aided Cabinet Dehydration

Desiccant-aided cabinet dehydration enhances moisture removal from vegetables by integrating desiccants that absorb ambient humidity, resulting in faster drying times and improved preservation compared to open-air methods. This controlled environment reduces oxidation and microbial growth, maintaining nutrient content and color more effectively than traditional open-air dehydrating.

Open-Air Dehydrating vs Enclosed Cabinet Dehydrating for veggies. Infographic

cookingdiff.com

cookingdiff.com