Ceramic crocks provide a traditional, breathable environment ideal for fermenting vegetables, allowing gases to escape while maintaining a stable temperature and moisture level. Kombucha continuous brewers are specifically designed for brewing kombucha, featuring an airlock and spigot system for easy sediment separation and continuous harvesting. Choosing between a ceramic crock and a kombucha continuous brewer depends on the type of fermentation and ease of use desired, with crocks excelling in vegetable fermenting and continuous brewers optimized for kombucha production.

Table of Comparison

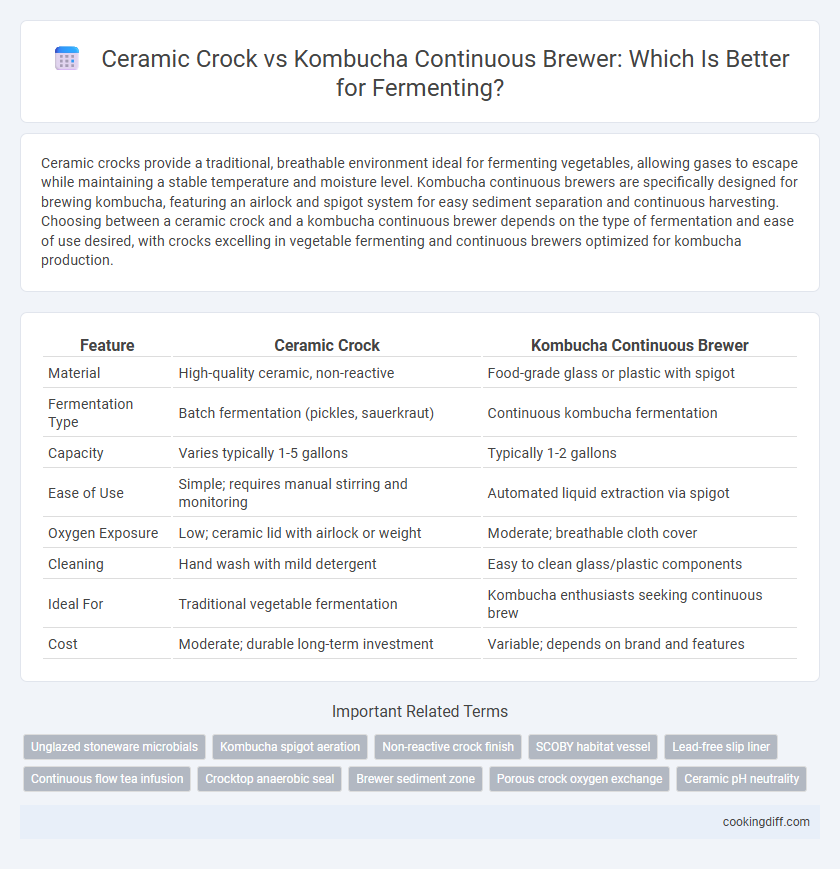

| Feature | Ceramic Crock | Kombucha Continuous Brewer |

|---|---|---|

| Material | High-quality ceramic, non-reactive | Food-grade glass or plastic with spigot |

| Fermentation Type | Batch fermentation (pickles, sauerkraut) | Continuous kombucha fermentation |

| Capacity | Varies typically 1-5 gallons | Typically 1-2 gallons |

| Ease of Use | Simple; requires manual stirring and monitoring | Automated liquid extraction via spigot |

| Oxygen Exposure | Low; ceramic lid with airlock or weight | Moderate; breathable cloth cover |

| Cleaning | Hand wash with mild detergent | Easy to clean glass/plastic components |

| Ideal For | Traditional vegetable fermentation | Kombucha enthusiasts seeking continuous brew |

| Cost | Moderate; durable long-term investment | Variable; depends on brand and features |

Introduction to Fermentation Vessels

Fermentation vessels play a crucial role in controlling the environment for microbial activity during fermentation. Ceramic crocks and kombucha continuous brewers offer different benefits based on their design and material properties.

- Ceramic crock - Provides a non-reactive, breathable environment ideal for fermenting vegetables, allowing gases to escape while keeping contaminants out.

- Kombucha continuous brewer - Designed for ongoing fermentation with a spigot for easy liquid extraction without disturbing the culture.

- Material impact - Ceramic retains temperature and moisture well, whereas glass or plastic in continuous brewers allows visual monitoring of the fermentation process.

Choosing the appropriate vessel depends on the type of fermentation and the desired control over the process.

What Is a Ceramic Crock?

A ceramic crock is a traditional fermentation vessel made from glazed clay, ideal for fermenting vegetables like sauerkraut and kimchi due to its non-reactive surface that maintains consistent temperature and moisture. Unlike kombucha continuous brewers, ceramic crocks do not have built-in spigots or airlocks, requiring manual handling and monitoring during the fermentation process. Their porous structure allows beneficial bacteria to thrive, enhancing the flavor and texture of the fermented product over time.

What Is a Kombucha Continuous Brewer?

A kombucha continuous brewer is a specialized vessel designed to ferment kombucha steadily without frequent batch turnover. Unlike traditional ceramic crocks that require manual emptying after each batch, continuous brewers allow for ongoing extraction of kombucha while maintaining the fermentation process uninterrupted.

- Continuous fermentation - Enables constant kombucha production by allowing fresh sweet tea to be added without disrupting the SCOBY.

- Built-in spigot - Features a faucet for easy, hygienic dispensing of finished kombucha directly from the brewer.

- Material advantages - Often made from glass or BPA-free plastic for visibility and fermentation control, differing from opaque ceramic crocks.

Material Differences: Ceramic vs. Glass

Ceramic crocks offer excellent insulation and maintain a stable temperature for fermenting, which is crucial for consistent fermentation. Glass in kombucha continuous brewers allows visual monitoring of the fermentation process without disturbing the environment.

Ceramic's porous nature can help regulate micro-oxygenation, benefiting certain fermentation types but requires careful cleaning to prevent contamination. Glass is non-porous, making it easier to sanitize and less likely to harbor unwanted bacteria. The choice between ceramic and glass hinges on balancing insulation properties with ease of maintenance in brewing setups.

Airflow and Contamination Risks

Ceramic crocks provide a natural, breathable environment that allows controlled airflow essential for fermentation while minimizing contamination risks through their non-porous glaze. Kombucha continuous brewers often feature airlocks or breathable lids that regulate oxygen exposure, reducing the chance of unwanted bacteria or mold infiltrating the ferment. Proper airflow management in both systems is critical to maintaining a healthy SCOBY and preventing spoilage during extended fermenting periods.

Capacity and Batch Size Comparison

| Fermentation Vessel | Capacity | Batch Size |

|---|---|---|

| Ceramic Crock | Typically ranges from 1 to 10 gallons | Batch sizes vary, often suitable for smaller home-batch fermentations |

| Kombucha Continuous Brewer | Commonly holds 1 to 5 gallons, designed for ongoing fermentation | Supports continuous batch size with regular partial harvests, enabling steady kombucha production |

Ease of Use and Maintenance

Ceramic crocks offer a simple, traditional fermentation process with minimal parts, making them easy to clean and maintain by hand. Their sturdy construction allows for natural temperature regulation, but requires manual monitoring and patience.

Kombucha continuous brewers feature built-in spigots and airlocks that streamline liquid extraction and reduce contamination risk, enhancing ease of use. However, their more complex design demands regular cleaning of multiple components to prevent mold and yeast buildup.

Flavor Development and Consistency

How do ceramic crocks compare to kombucha continuous brewers in flavor development and consistency during fermentation? Ceramic crocks allow for slow, natural fermentation that enhances complex, deep flavors through micro-oxygenation and temperature stability. Kombucha continuous brewers provide more consistent fermentation results with controlled conditions, producing predictable flavors but less variability compared to traditional ceramic fermentation.

Cost and Availability

Ceramic crocks for fermenting are generally more affordable and widely available in kitchenware stores and online marketplaces, making them a budget-friendly option for beginners. These crocks range from $30 to $100 depending on size and craftsmanship, offering a cost-effective solution for various fermentation projects.

Kombucha continuous brewers typically cost between $70 and $150 and are often found in specialty brewing shops or online, which can limit immediate availability compared to ceramic crocks. Their price reflects the convenience and design tailored specifically for kombucha fermentation, appealing primarily to enthusiasts focused on this beverage.

Related Important Terms

Unglazed stoneware microbials

Unglazed stoneware ceramic crocks provide an ideal environment for fermenting due to their porous surface, which promotes healthy microbial growth and enhances flavor complexity in fermented foods like sauerkraut and kimchi. In contrast, kombucha continuous brewers, often made from glass or food-safe plastics, lack porous microenvironments, resulting in less natural microbial interaction and potentially slower probiotic development.

Kombucha spigot aeration

Ceramic crocks provide traditional anaerobic conditions ideal for fermentation, while kombucha continuous brewers with spigots introduce controlled aeration that supports the SCOBY's oxygen requirements for optimal kombucha fermentation. The spigot design minimizes contamination risk and facilitates convenient harvesting without disturbing the brew, enhancing both flavor development and fermentation consistency.

Non-reactive crock finish

Ceramic crocks with a non-reactive finish provide an ideal environment for fermenting due to their inert surface, which prevents unwanted chemical reactions and preserves the natural flavors of kombucha. In contrast, kombucha continuous brewers often contain metal or plastic components that can leach into the brew, risking contamination and altering fermentation quality.

SCOBY habitat vessel

Ceramic crocks provide a stable, inert environment with excellent temperature regulation, ideal for SCOBY health during kombucha fermentation. Kombucha continuous brewers offer a controlled, oxygen-permeable vessel specifically designed to maintain optimal SCOBY habitat conditions and streamline continuous fermentation cycles.

Lead-free slip liner

Ceramic crocks with lead-free slip liners provide a safe, non-reactive environment essential for traditional fermentation, preserving the flavor integrity and preventing harmful metal leaching. Kombucha continuous brewers often utilize BPA-free plastic or glass but may lack the durable slip liner that ceramic crocks offer, which enhances the longevity and safety of long-term fermentation processes.

Continuous flow tea infusion

Ceramic crocks offer traditional fermentation with natural breathability and micro-oxygenation, ideal for batch fermentation of sauerkraut and pickles, while kombucha continuous brewers provide precise temperature control and continuous flow tea infusion, enhancing probiotic development and flavor consistency during extended fermentation cycles. Continuous flow brewers enable automated nutrient replenishment and sediment separation, optimizing kombucha production efficiency and scalability compared to static ceramic crock fermentation.

Crocktop anaerobic seal

The Ceramic crock with a Crocktop anaerobic seal ensures an oxygen-free environment essential for authentic fermentation, preserving beneficial bacteria and preventing contamination. In contrast, kombucha continuous brewers typically allow oxygen exposure, which may alter flavor profiles and reduce anaerobic fermentation benefits.

Brewer sediment zone

Ceramic crocks provide a stable sediment zone where yeast and bacteria naturally settle during fermentation, promoting balanced microbial activity and flavor development. Kombucha continuous brewers feature a designated sediment zone that facilitates efficient SCOBY growth and sediment separation, enhancing clarity and continuous fermentation cycles.

Porous crock oxygen exchange

Ceramic crocks, due to their porous nature, allow for natural oxygen exchange essential for traditional fermentation, enhancing microbial activity and flavor complexity. Kombucha continuous brewers, typically non-porous and airtight, limit oxygen exposure to control yeast and bacteria growth, optimizing the fermentation process specifically for kombucha.

Ceramic crock vs kombucha continuous brewer for fermenting. Infographic

cookingdiff.com

cookingdiff.com