A plastic lid offers a secure, airtight seal ideal for preventing contamination during pet fermentation but may trap gases, risking pressure buildup. Pickle pipes allow gases to escape through a water-lock system, reducing the chance of explosion and preserving anaerobic conditions essential for proper fermentation. Choosing between the two depends on balancing convenience and safety for a successful fermentation process.

Table of Comparison

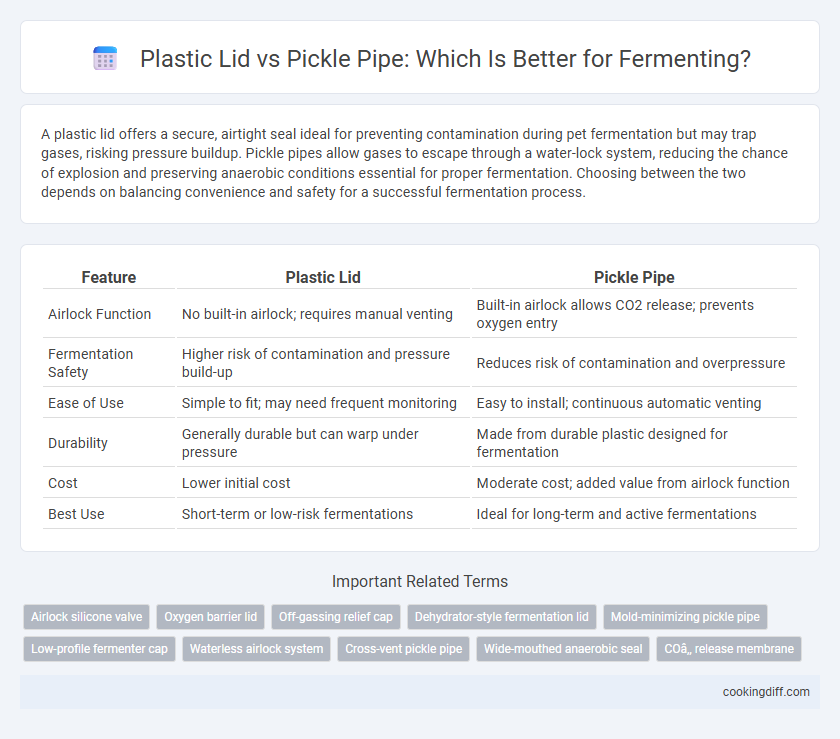

| Feature | Plastic Lid | Pickle Pipe |

|---|---|---|

| Airlock Function | No built-in airlock; requires manual venting | Built-in airlock allows CO2 release; prevents oxygen entry |

| Fermentation Safety | Higher risk of contamination and pressure build-up | Reduces risk of contamination and overpressure |

| Ease of Use | Simple to fit; may need frequent monitoring | Easy to install; continuous automatic venting |

| Durability | Generally durable but can warp under pressure | Made from durable plastic designed for fermentation |

| Cost | Lower initial cost | Moderate cost; added value from airlock function |

| Best Use | Short-term or low-risk fermentations | Ideal for long-term and active fermentations |

Introduction to Fermentation Lids: Plastic vs Pickle Pipe

Fermentation lids play a crucial role in maintaining an anaerobic environment while allowing gases to escape, essential for successful fermentation. Plastic lids are commonly used for their affordability and ease of use, whereas pickle pipes offer a specialized solution designed to release carbon dioxide efficiently without letting oxygen in.

Plastic lids often require occasional manual burping to release built-up gases, which can interrupt the fermentation process and increase contamination risks. Pickle pipes, also known as airlock lids, create a one-way valve system that continuously vents gases and maintains a sealed, oxygen-free environment. Selecting between plastic lids and pickle pipes depends on the fermenter's preference for convenience, cost, and control over the fermentation atmosphere.

What is a Plastic Lid for Fermentation?

A plastic lid for fermentation is a specially designed cover that seals fermentation vessels to maintain an anaerobic environment while allowing gas to escape. It prevents contamination and controls airflow, ensuring optimal conditions for microbial activity during fermentation.

- Airlock feature - The plastic lid often includes an integrated airlock or valve that releases carbon dioxide without letting oxygen in.

- Durability and fit - Made from food-grade plastic, these lids provide a secure, reusable seal compatible with various fermentation jars.

- Ease of use - Plastic lids simplify monitoring and managing fermentations by reducing the risk of contamination and requiring minimal maintenance.

Understanding the Pickle Pipe Airlock System

The Pickle Pipe airlock system allows gases to escape from the fermenting vessel while preventing contaminants from entering, ensuring a controlled fermentation environment. Compared to a plastic lid, the Pickle Pipe offers a more reliable release of carbon dioxide without the risk of pressure buildup.

- Effective Gas Release - The Pickle Pipe vents excess CO2 produced during fermentation to avoid jar explosions.

- Contaminant Protection - Its water-filled chamber blocks oxygen and airborne bacteria from spoiling the ferment.

- Pressure Regulation - Unlike a sealed plastic lid, the airlock system maintains optimal internal pressure for active fermentation.

Comparing Air Exchange Mechanisms

Plastic lids rely on manual venting or small holes to allow gas escape, while pickle pipes provide a continuous and controlled air exchange through water-sealed channels. The air exchange mechanism in pickle pipes prevents oxidation more effectively by maintaining an anaerobic environment compared to plastic lids.

- Plastic Lid Air Exchange - Typically requires manual loosening or a built-in valve to release fermentation gases.

- Pickle Pipe Design - Uses a water-airlock system to allow CO2 to escape without letting oxygen or contaminants in.

- Oxygen Exposure Risk - Plastic lids can permit more oxygen exposure, potentially impacting fermentation quality.

Pickle pipes optimize fermentation by maintaining consistent anaerobic conditions through superior air exchange control.

Factors Affecting Oxygen Control in Fermentation

Plastic lids often create a tighter seal, reducing oxygen exposure and limiting unwanted aerobic microbial growth during fermentation. Pickle pipes provide a controlled release of carbon dioxide while minimizing oxygen entry, which is crucial for maintaining an anaerobic environment favorable for lactic acid bacteria. The choice between a plastic lid and a pickle pipe significantly impacts oxygen control, thereby influencing fermentation speed, flavor development, and spoilage risk.

Mold and Contamination Risks: Plastic Lid vs Pickle Pipe

Plastic lids can trap moisture and create anaerobic conditions that may promote mold growth during fermentation. This environment increases the risk of contamination, potentially spoiling the batch.

Pickle pipes allow gases to escape while preventing oxygen and contaminants from entering, significantly reducing mold risk. Their airlock design ensures a cleaner ferment by minimizing exposure to airborne spores and bacteria.

Ease of Use and Maintenance

Which is easier to use and maintain: a plastic lid or a pickle pipe for fermenting? A plastic lid offers a straightforward setup with minimal cleaning required, making it highly user-friendly for beginners. Pickle pipes demand more careful handling and thorough rinsing to prevent clogging, but they allow for better gas release during fermentation.

Fermentation Results: Taste and Texture Differences

Plastic lids often create a tighter seal, which can lead to a more anaerobic environment, promoting a tangier taste in fermented products. This can enhance the crispness but might result in softer textures due to trapped gases.

Pickle pipes allow excess gas to escape while minimizing oxygen exposure, preserving a balanced flavor profile with a more natural, crunchy texture. The controlled airflow typically results in fermentation with fewer off-flavors and better preservation of the vegetable's original firmness.

Cost-Effectiveness and Availability

| Plastic Lid | Widely available and affordable, with prices typically ranging from $1 to $5; easy to source online or in stores. |

| Pickle Pipe | Often more expensive, generally costing between $10 and $20, and less commonly stocked in local shops. |

| Cost-Effectiveness | Plastic lids offer a budget-friendly option ideal for beginners or large-scale fermenting, while pickle pipes provide specialized functionality at a higher price point. |

| Availability | Plastic lids are available in multiple sizes and materials, enhancing accessibility; pickle pipes may require ordering from niche fermenting suppliers. |

Related Important Terms

Airlock silicone valve

The airlock silicone valve in both plastic lids and pickle pipes provides essential gas release to prevent oxygen exposure while maintaining an anaerobic environment during fermentation. Plastic lids with integrated airlock valves offer a compact, reliable seal, whereas pickle pipes excel in flexibility and ease of cleaning, making the choice dependent on user preference for convenience or durability.

Oxygen barrier lid

Plastic lids with oxygen barrier properties create a more anaerobic environment by limiting air exposure during fermenting, which helps prevent mold and spoilage in pickles. Pickle pipes allow CO2 to escape while minimizing oxygen entry, but oxygen barrier plastic lids often provide a more consistent seal to maintain ideal fermentation conditions.

Off-gassing relief cap

Plastic lids with built-in airlocks provide efficient off-gassing relief during fermentation, preventing pressure buildup without exposing the batch to contaminants. Pickle pipes offer a traditional, cost-effective method for releasing gases but may require frequent monitoring to avoid leaks or blockages.

Dehydrator-style fermentation lid

The Dehydrator-style fermentation lid offers superior air circulation and moisture control compared to traditional plastic lids or pickle pipes, reducing the risk of mold and ensuring consistent fermentation. Its design allows CO2 to escape while preventing contaminants from entering, optimizing the anaerobic environment crucial for high-quality fermented products.

Mold-minimizing pickle pipe

A pickle pipe creates a controlled environment that reduces the exposure of fermenting vegetables to oxygen, which significantly minimizes mold growth compared to plastic lids that can trap air and moisture inconsistently. Its design allows carbon dioxide to escape while preventing airborne contaminants, ensuring a cleaner and more consistent fermentation process.

Low-profile fermenter cap

Low-profile fermenter caps offer an optimized seal that minimizes air exposure while allowing gas to escape, reducing the risk of contamination during fermentation. Compared to plastic lids, their slim design and integrated airlock ports ensure better pressure control and a more consistent environment for fermenting vegetables or beverages.

Waterless airlock system

Plastic lids for fermenting provide an affordable, reusable seal but often lack effective gas release, leading to potential pressure buildup or contamination. Pickle pipes use a waterless airlock system that allows carbon dioxide to escape while preventing oxygen and contaminants from entering, ensuring anaerobic fermentation without mess or water maintenance.

Cross-vent pickle pipe

A cross-vent pickle pipe enables controlled release of fermentation gases while preventing oxygen and contaminants from entering, making it more effective than traditional plastic lids for preserving flavor and preventing spoilage during vegetable fermentation. Unlike plastic lids that can trap pressure and cause risk of explosion or require frequent burping, pickle pipes maintain an ideal anaerobic environment with minimal maintenance.

Wide-mouthed anaerobic seal

Wide-mouthed anaerobic seals found in plastic lids provide a tight, oxygen-free environment crucial for successful fermentation by preventing air exposure and contamination. However, pickle pipes with airlock systems allow CO2 to escape while maintaining anaerobic conditions, minimizing pressure buildup and enhancing the safety of fermenting vegetables.

Plastic lid vs Pickle pipe for fermenting. Infographic

cookingdiff.com

cookingdiff.com