Ceramic crocks offer a traditional and natural environment for fermenting pet foods, maintaining consistent temperatures and allowing gases to escape through their porous material. Vacuum fermenters provide a more controlled atmosphere by removing oxygen, reducing spoilage risk and extending shelf life of fermented pet products. Choosing between ceramic crocks and vacuum fermenters depends on the desired fermentation style and equipment preferences for optimal pet food quality.

Table of Comparison

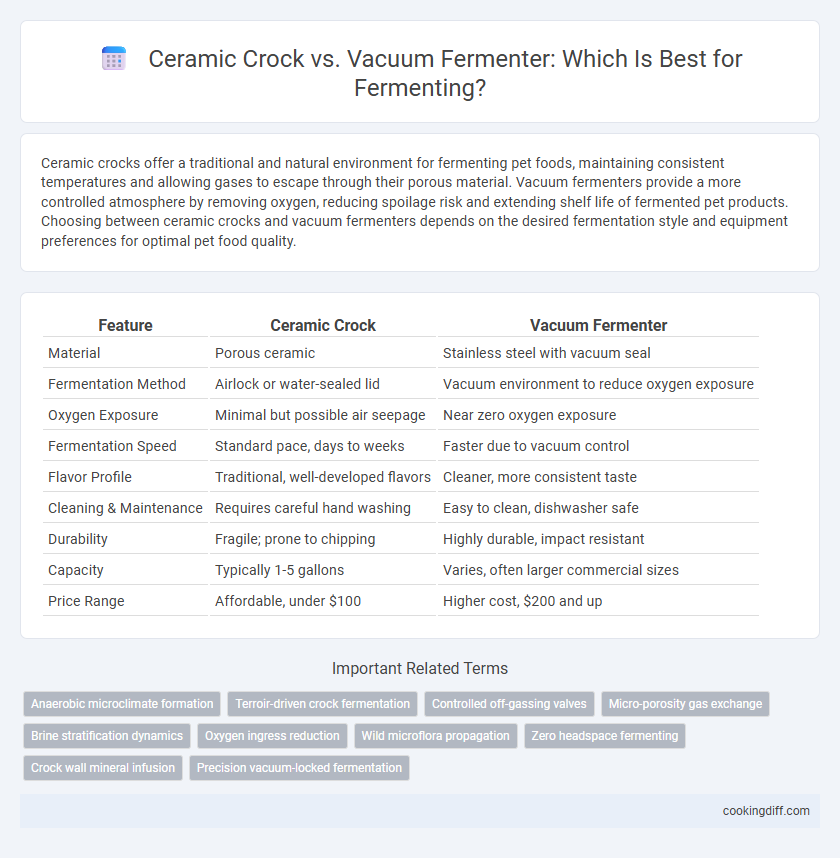

| Feature | Ceramic Crock | Vacuum Fermenter |

|---|---|---|

| Material | Porous ceramic | Stainless steel with vacuum seal |

| Fermentation Method | Airlock or water-sealed lid | Vacuum environment to reduce oxygen exposure |

| Oxygen Exposure | Minimal but possible air seepage | Near zero oxygen exposure |

| Fermentation Speed | Standard pace, days to weeks | Faster due to vacuum control |

| Flavor Profile | Traditional, well-developed flavors | Cleaner, more consistent taste |

| Cleaning & Maintenance | Requires careful hand washing | Easy to clean, dishwasher safe |

| Durability | Fragile; prone to chipping | Highly durable, impact resistant |

| Capacity | Typically 1-5 gallons | Varies, often larger commercial sizes |

| Price Range | Affordable, under $100 | Higher cost, $200 and up |

Introduction to Fermenting Vessels

Fermenting vessels are essential for cultivating beneficial bacteria in food preservation. Ceramic crocks and vacuum fermenters offer unique environments that influence the fermentation process.

- Ceramic crock - Porous material allows slow air exchange, supporting natural fermentation without harmful oxidation.

- Vacuum fermenter - Removes air to create an anaerobic environment, accelerating fermentation and reducing spoilage risk.

- Material impact - The choice between ceramic and vacuum vessels affects flavor development and fermentation control.

Overview of Ceramic Crocks

What makes ceramic crocks a popular choice for fermenting? Ceramic crocks offer a naturally breathable environment that promotes beneficial microbial activity, essential for traditional fermentation processes. Their heavy, non-reactive material maintains consistent temperatures and prevents contamination, making them ideal for fermenting vegetables like sauerkraut and kimchi.

Overview of Vacuum Fermenters

Vacuum fermenters create a low-oxygen environment that speeds up the fermentation process while enhancing flavor development. These devices use adjustable pressure settings to control fermentation variables, resulting in consistent and high-quality fermented products.

- Oxygen Control - Maintains an oxygen-free environment to reduce spoilage and support anaerobic fermentation.

- Pressure Regulation - Allows precise adjustment of internal pressure to optimize microbial activity and flavor extraction.

- Fermentation Speed - Accelerates fermentation up to 50% faster compared to traditional ceramic crocks by minimizing oxidation.

Fermentation Process Comparison

Ceramic crocks offer a traditional fermentation environment with natural air exchange, promoting the growth of beneficial bacteria through slow, steady oxygen exposure. Vacuum fermenters create an anaerobic atmosphere by removing air, accelerating fermentation and reducing the risk of mold and spoilage.

The consistent low oxygen levels in vacuum fermenters enhance lactic acid bacteria activity, resulting in faster souring and more controlled flavor profiles. Ceramic crocks require careful water sealing to maintain an ideal environment but allow more nuanced microbial diversity due to their porous material.

Flavor and Texture Outcomes

Ceramic crocks provide a stable, anaerobic environment that enhances complex flavor development and yields a crisp, traditional texture in fermented vegetables. Vacuum fermenters, by contrast, accelerate fermentation while preserving bright flavors and tender textures through controlled oxygen exclusion.

The porous nature of ceramic crocks facilitates beneficial microbial activity, contributing to richer, more nuanced fermentation profiles over extended periods. Vacuum fermenters maintain consistent pressure and reduce oxidation, resulting in uniformly textured products with vibrant, fresh taste notes. Choosing between these methods depends on desired fermentation speed and flavor intensity preferences.

Ease of Use and Maintenance

Ceramic crocks offer simple, hands-on fermentation with minimal equipment, making them easy to use for beginners but requiring regular water sealing and cleaning to prevent mold. Vacuum fermenters streamline the process by maintaining an airtight environment, reducing the need for manual monitoring and decreasing contamination risk. Maintenance for vacuum fermenters involves occasional filter replacement and ensuring the vacuum seal integrity, which is less intensive than the daily checks ceramic crocks demand.

Food Safety and Airflow Control

Ceramic crocks offer natural breathability and create an anaerobic environment crucial for safe fermentation, minimizing the risk of harmful bacteria growth. Their non-reactive surface prevents contamination, ensuring food safety during the fermentation process.

Vacuum fermenters provide precise airflow control by actively removing oxygen, which enhances fermentation consistency and reduces spoilage risks. This controlled environment also limits exposure to external contaminants, further improving food safety standards.

Durability and Longevity

Ceramic crocks offer exceptional durability with thick walls that resist chipping and cracking, often lasting decades with proper care. Vacuum fermenters are constructed from high-quality stainless steel or durable plastic, designed to withstand pressure while preventing oxidation, thus extending their usable lifespan. Both options provide long-term reliability, but ceramic crocks tend to have a longer lifespan due to their resistance to corrosion and chemical reactions during fermentation.

Cost and Accessibility

| Ceramic Crock | Ceramic crocks are generally more affordable and widely accessible through kitchenware stores and online retailers. They require no electricity, making them cost-effective over time with minimal maintenance expenses. Their traditional design supports natural fermentation but may have variable sealing effectiveness compared to vacuum fermenters. |

| Vacuum Fermenter | Vacuum fermenters tend to have a higher upfront cost due to the integrated vacuum technology and specialized components. These fermenters may be less accessible in standard retail locations, often requiring purchase through specialty suppliers or online platforms. Their efficient sealing mechanism helps reduce spoilage, potentially offsetting initial investment with improved fermentation consistency. |

Related Important Terms

Anaerobic microclimate formation

Ceramic crocks naturally create an anaerobic microclimate through their heavy lids that allow gases to escape without letting oxygen in, promoting optimal fermentation. Vacuum fermenters actively remove oxygen by sealing and extracting air, ensuring a tightly controlled anaerobic environment that accelerates the fermentation process and reduces spoilage risks.

Terroir-driven crock fermentation

Ceramic crocks enhance terroir-driven fermentation by providing a stable, breathable environment that allows local microflora to thrive, preserving unique regional flavors and characteristics in fermented products. In contrast, vacuum fermenters create an anaerobic environment that limits microbial diversity, potentially reducing the distinctiveness imparted by natural terroir during the fermentation process.

Controlled off-gassing valves

Ceramic crocks rely on manual water-sealed airlocks to allow off-gassing while preventing oxygen exposure, whereas vacuum fermenters utilize built-in controlled off-gassing valves that automatically regulate pressure and release gases without air ingress. This automated valve system in vacuum fermenters ensures consistent anaerobic fermentation conditions, reducing the risk of spoilage and improving ferment quality compared to traditional ceramic crocks.

Micro-porosity gas exchange

Ceramic crocks offer natural micro-porosity that allows slow gas exchange, supporting the release of carbon dioxide while preventing oxygen from entering, which enhances anaerobic fermentation and flavor development. In contrast, vacuum fermenters create a sealed environment that eliminates oxygen exposure entirely but lack the subtle gas regulation provided by ceramic micro-porosity, potentially affecting microbial activity and fermentation complexity.

Brine stratification dynamics

Ceramic crocks naturally promote brine stratification through gradual temperature changes and porous material breathability, fostering diverse microbial activity essential for traditional fermentation. In contrast, vacuum fermenters maintain uniform pressure and reduced oxygen exposure, minimizing stratification but accelerating anaerobic fermentation with consistent brine composition throughout.

Oxygen ingress reduction

Ceramic crocks naturally limit oxygen exposure through their thick, non-porous walls, creating an anaerobic environment ideal for fermentation; vacuum fermenters further reduce oxygen ingress by actively removing air and sealing the container, enhancing preservation and flavor development. Both methods prevent aerobic spoilage, but vacuum fermenters offer precise control over oxygen levels, making them superior for consistent, high-quality fermenting.

Wild microflora propagation

Ceramic crocks provide a natural environment that encourages wild microflora propagation through their breathable and porous walls, enabling beneficial bacteria to thrive during fermentation. Vacuum fermenters, although efficient in controlling oxygen exposure, may limit the diversity and activity of wild microflora by creating an anaerobic environment less conducive to natural microbial growth.

Zero headspace fermenting

Ceramic crocks provide natural breathability and maintain ideal anaerobic conditions for fermenting with zero headspace, minimizing oxidation and mold risk. Vacuum fermenters ensure precise zero headspace control by actively removing air, accelerating fermentation and preserving nutrients more efficiently.

Crock wall mineral infusion

Ceramic crocks provide natural mineral infusion through their porous walls, enhancing the fermentation process by promoting beneficial microbial activity and improving flavor complexity. Unlike vacuum fermenters, which rely on sealed environments to control oxygen exposure, the mineral-rich ceramic walls create a dynamic microenvironment that supports healthier lacto-fermentation and nutrient retention.

Ceramic crock vs vacuum fermenter for fermenting Infographic

cookingdiff.com

cookingdiff.com