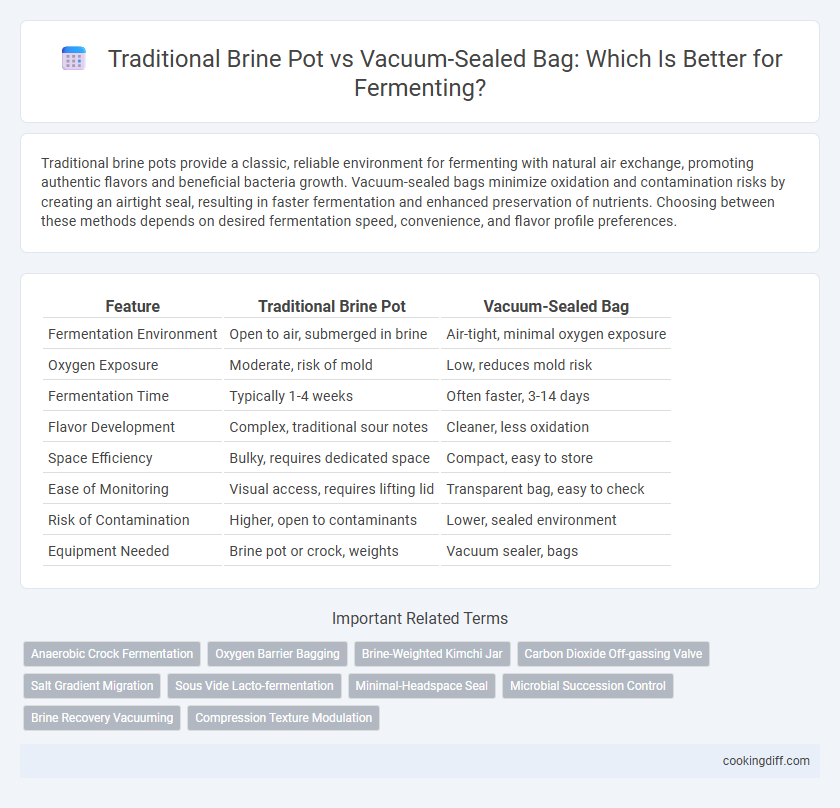

Traditional brine pots provide a classic, reliable environment for fermenting with natural air exchange, promoting authentic flavors and beneficial bacteria growth. Vacuum-sealed bags minimize oxidation and contamination risks by creating an airtight seal, resulting in faster fermentation and enhanced preservation of nutrients. Choosing between these methods depends on desired fermentation speed, convenience, and flavor profile preferences.

Table of Comparison

| Feature | Traditional Brine Pot | Vacuum-Sealed Bag |

|---|---|---|

| Fermentation Environment | Open to air, submerged in brine | Air-tight, minimal oxygen exposure |

| Oxygen Exposure | Moderate, risk of mold | Low, reduces mold risk |

| Fermentation Time | Typically 1-4 weeks | Often faster, 3-14 days |

| Flavor Development | Complex, traditional sour notes | Cleaner, less oxidation |

| Space Efficiency | Bulky, requires dedicated space | Compact, easy to store |

| Ease of Monitoring | Visual access, requires lifting lid | Transparent bag, easy to check |

| Risk of Contamination | Higher, open to contaminants | Lower, sealed environment |

| Equipment Needed | Brine pot or crock, weights | Vacuum sealer, bags |

Introduction: Fermentation Methods in Focus

Traditional brine pots have been used for centuries to ferment vegetables, relying on natural anaerobic conditions created by the salty water solution. These ceramic or stoneware containers allow gases to escape while preventing oxygen from entering, fostering a controlled environment for beneficial bacteria.

Vacuum-sealed bags represent a modern fermenting method, removing air to accelerate fermentation and reduce oxidation risks. This technique offers a compact, space-saving alternative that can enhance flavor development and minimize contamination during the fermentation process.

Traditional Brine Pots: Heritage and Principles

Traditional brine pots have been used for centuries in fermentation, preserving vegetables through natural lacto-fermentation processes. These earthenware containers maintain optimal temperatures and moisture levels, fostering the growth of beneficial bacteria essential for authentic flavors.

Heritage brine pots are porous, allowing gases to escape while preventing oxygen infiltration, which is crucial in preventing spoilage. Their time-tested design supports gradual fermentation, producing rich textures and complex probiotic profiles unmatched by vacuum-sealed bags.

Vacuum-Sealed Bags: Modern Innovation in Fermentation

Vacuum-sealed bags offer a modern, oxygen-free environment that accelerates fermentation while preventing mold growth. This innovation enhances flavor consistency and reduces the risk of contamination compared to traditional brine pots.

- Oxygen Removal - Vacuum-sealed bags eliminate air exposure, promoting anaerobic fermentation essential for preserving nutrients and enhancing taste.

- Space Efficiency - These bags are compact and flexible, making them ideal for small kitchens and easy storage during fermentation.

- Reduced Contamination - The sealed environment minimizes contact with airborne bacteria, ensuring a safer fermentation process.

Flavor Development: Brine Pot vs Vacuum-Sealed Techniques

| Traditional Brine Pot | Enhances complex flavor profiles through natural microbial activity and oxygen exposure, promoting rich fermentation depth. |

| Vacuum-Sealed Bag | Limits oxygen contact, resulting in milder, cleaner flavors and faster fermentation with reduced risk of spoilage. |

Texture and Consistency: Comparing Ferment Results

How do traditional brine pots and vacuum-sealed bags affect the texture and consistency of fermented foods? Traditional brine pots allow for natural gas exchange, resulting in a more complex, slightly varied texture with a handmade feel. Vacuum-sealed bags create a uniform, denser consistency by minimizing oxygen exposure and maintaining constant pressure throughout the fermentation process.

Safety and Shelf Life: Microbial Control in Both Methods

Traditional brine pots create an anaerobic environment that promotes beneficial lactobacillus growth while inhibiting harmful bacteria, enhancing safety through natural microbial control. Vacuum-sealed bags reduce oxygen exposure effectively, extending shelf life by limiting spoilage organisms, but require careful monitoring to prevent anaerobic pathogens like Clostridium botulinum. Both methods demand strict hygiene and temperature regulation to ensure optimal fermentation safety and preservation.

Equipment and Cost: Budget and Accessibility Factors

Traditional brine pots are often more affordable and accessible for beginners due to their simple design and reusable materials. Vacuum-sealed bags require investment in specialized equipment but offer precise control over fermentation conditions.

- Cost-effectiveness of brine pots - Typically made from ceramic or glass, brine pots are cost-efficient and widely available in most household stores.

- Initial investment in vacuum-sealed bags - Requires purchasing a vacuum sealer and compatible bags, increasing upfront costs but potentially saving money long-term by reducing spoilage.

- Accessibility and ease of use - Brine pots need minimal setup, making them accessible for home fermenters, while vacuum-sealed methods may involve a learning curve and reliance on electronic devices.

Space and Convenience: Storage and Practicality

Traditional brine pots require substantial counter or cellar space due to their bulky ceramic design, making storage challenging in smaller kitchens. Vacuum-sealed bags significantly reduce the footprint by collapsing as the contents ferment, allowing for compact storage in refrigerators or tight spaces. Their lightweight and flexible nature offer enhanced practicality and ease of handling compared to the rigid, heavy brine pots.

Environmental Impact: Sustainability Considerations

Traditional brine pots, often made from natural materials like ceramic or glass, offer a reusable and biodegradable option that minimizes plastic waste in fermentation. Vacuum-sealed bags, typically constructed from plastics, contribute to environmental concerns due to their single-use nature and challenges in recycling.

Using traditional brine pots aligns with sustainable practices by reducing reliance on synthetic materials and lowering carbon footprints associated with production and disposal. Vacuum-sealed bags require energy-intensive manufacturing processes and often end up in landfills, exacerbating pollution and resource depletion. Choosing ceramic or glass fermentation vessels supports eco-friendly lifestyles by promoting durability and reducing plastic consumption.

Related Important Terms

Anaerobic Crock Fermentation

Traditional brine pots provide a reliable anaerobic environment essential for crock fermentation by using water-seal rims that prevent oxygen exposure while allowing gases to escape naturally. In contrast, vacuum-sealed bags create a tighter anaerobic seal but may risk texture alteration due to uneven pressure, making brine pots preferred for authentic fermentation with consistent microbial activity.

Oxygen Barrier Bagging

Traditional brine pots provide a natural anaerobic environment for fermentation but may allow minimal oxygen exposure at the surface, potentially affecting flavor and microbial activity. Vacuum-sealed bags offer superior oxygen barrier properties by removing air, ensuring consistent anaerobic conditions that enhance fermentation control and reduce spoilage risks.

Brine-Weighted Kimchi Jar

The Brine-Weighted Kimchi Jar provides a traditional fermentation method that maintains anaerobic conditions by using weighted brine to submerge vegetables, enhancing flavor development and texture preservation. Unlike vacuum-sealed bags, which can sometimes cause uneven fermentation due to inconsistent pressure, the weighted jar ensures uniform brine coverage and optimal gas release for consistent sourness and crunch.

Carbon Dioxide Off-gassing Valve

Traditional brine pots incorporate carbon dioxide off-gassing valves that allow gases produced during fermentation to escape while preventing air from entering, reducing the risk of mold and spoilage. In contrast, vacuum-sealed bags utilize flexible materials that expand as CO2 is released, providing an airtight environment that enhances anaerobic fermentation and preserves flavor.

Salt Gradient Migration

Traditional brine pots rely on natural salt gradient migration to regulate fermentation, allowing beneficial microbes to thrive as salt concentration evenly distributes from the brine to the fermenting vegetables. Vacuum-sealed bags minimize salt gradient migration by creating an anaerobic environment that maintains uniform salt levels, resulting in faster fermentation with reduced risk of spoilage bacteria.

Sous Vide Lacto-fermentation

Traditional brine pots enable natural lacto-fermentation by maintaining consistent anaerobic conditions, but vacuum-sealed bags combined with sous vide precision offer enhanced control over temperature and fermentation duration, resulting in accelerated flavor development and improved texture in fermented products. Sous vide lacto-fermentation in vacuum-sealed bags also significantly reduces contamination risks by tightly sealing ingredients from external air exposure, optimizing microbial growth for superior probiotic benefits.

Minimal-Headspace Seal

Traditional brine pots maintain fermentation with a natural minimal-headspace seal, preventing air exposure and promoting anaerobic conditions essential for lacto-fermentation. Vacuum-sealed bags optimize this environment by reducing oxygen levels even further, ensuring a consistent seal that minimizes spoilage and enhances flavor development.

Microbial Succession Control

Traditional brine pots facilitate microbial succession by allowing natural oxygen exchange, promoting a diverse and gradual development of lactic acid bacteria essential for fermentation. Vacuum-sealed bags create an anaerobic environment that accelerates lactic acid bacteria dominance, providing precise control over microbial succession and reducing the risk of spoilage organisms.

Brine Recovery Vacuuming

Traditional brine pots rely on natural fermentation with brine submersion, often resulting in brine loss and inconsistent salt concentration, while vacuum-sealed bags enable superior brine recovery by minimizing exposure to air and reducing evaporation. Vacuum-sealed fermentation maintains optimal salt content and promotes anaerobic conditions, enhancing flavor development and preventing spoilage more effectively than traditional methods.

Traditional brine pot vs Vacuum-sealed bag for fermenting. Infographic

cookingdiff.com

cookingdiff.com