The open-bowl method for fermenting pet food allows for easy access and thorough monitoring of the fermentation process, promoting natural air circulation essential for beneficial bacterial growth. In contrast, the fermenting sleeve provides a controlled environment that limits exposure to contaminants while maintaining optimal humidity and temperature, which can enhance consistency and safety. Choosing between these methods depends on the desired fermentation control, convenience, and potential contamination risk for pet food preparation.

Table of Comparison

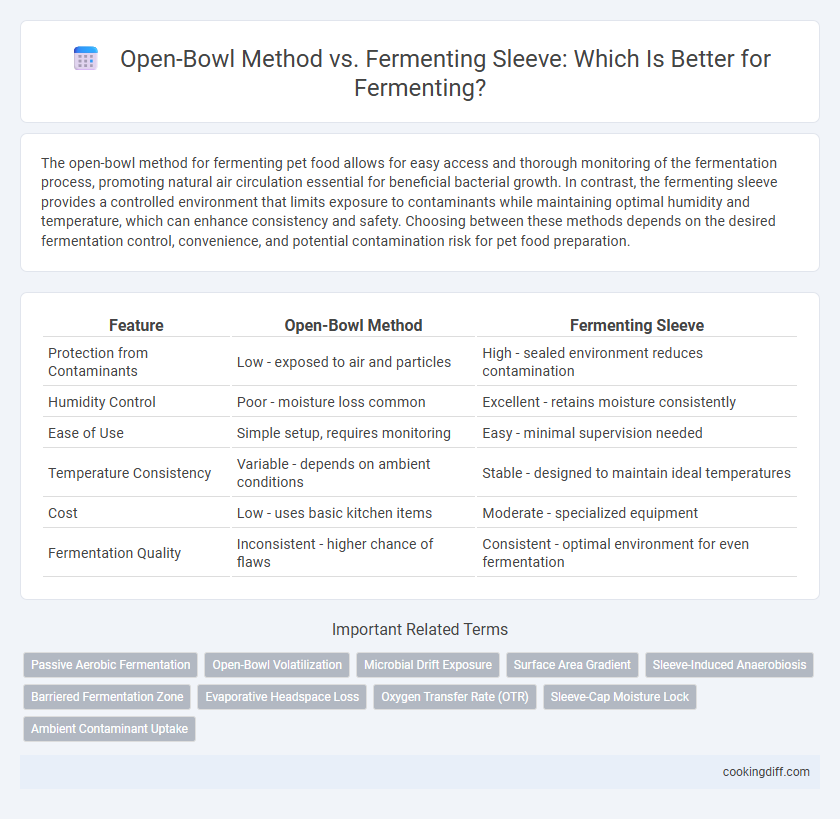

| Feature | Open-Bowl Method | Fermenting Sleeve |

|---|---|---|

| Protection from Contaminants | Low - exposed to air and particles | High - sealed environment reduces contamination |

| Humidity Control | Poor - moisture loss common | Excellent - retains moisture consistently |

| Ease of Use | Simple setup, requires monitoring | Easy - minimal supervision needed |

| Temperature Consistency | Variable - depends on ambient conditions | Stable - designed to maintain ideal temperatures |

| Cost | Low - uses basic kitchen items | Moderate - specialized equipment |

| Fermentation Quality | Inconsistent - higher chance of flaws | Consistent - optimal environment for even fermentation |

Introduction: Understanding Fermentation Techniques

| The open-bowl method exposes fermenting ingredients directly to air, promoting natural yeast activity and enhancing flavor complexity. Fermenting sleeves provide a controlled environment, reducing contamination risks and maintaining consistent temperature and humidity levels. Selecting between these methods depends on the desired fermentation outcome and level of process control. |

Open-bowl Method vs Fermenting Sleeve: Overview

Which method provides better airflow and control during fermentation: the Open-bowl Method or the Fermenting Sleeve? The Open-bowl Method allows maximum exposure to ambient air, promoting natural yeast activity but increasing the risk of contaminants. Fermenting Sleeves offer a controlled environment with adjustable airflow, reducing contamination while maintaining consistent fermentation conditions.

Equipment Needed for Open-bowl Fermentation

Open-bowl fermentation requires minimal equipment, making it accessible for beginners and small-batch fermenters. This method primarily depends on the right container and cover to maintain an optimal environment for the fermentation process.

- Fermentation Bowl - A non-reactive, wide-mouthed bowl made of glass, ceramic, or food-grade plastic is essential to allow gases to escape and facilitate easy monitoring.

- Covering Material - A breathable cloth or paper towel secured with a rubber band helps protect the contents from contaminants while allowing airflow.

- Weight or Divider - Optional weights or leaves can be used to keep the fermenting materials submerged and prevent mold growth on the surface.

Setting Up a Fermenting Sleeve System

Setting up a fermenting sleeve system requires ensuring the sleeve is properly sealed around the vessel to maintain an anaerobic environment essential for optimal fermentation. The sleeve must be inflated and securely fastened to prevent oxygen infiltration, which can adversely affect microbial activity and flavor development. This method offers consistent temperature control and reduced contamination risks compared to traditional open-bowl fermenting techniques.

Oxygen Exposure: Pros and Cons

The open-bowl method allows greater oxygen exposure, which can enhance the development of sourdough flavors and promote wild yeast activity during fermentation. However, this increased oxygen contact also raises the risk of surface drying and contamination from airborne particles.

Fermenting sleeves limit oxygen exposure by creating a sealed environment that retains moisture and protects the dough from external contaminants. Reduced oxygen levels slow oxidation, preserving dough quality but may result in less complex flavor profiles compared to open-bowl fermentation.

Contamination Risks and Prevention

The open-bowl method exposes fermenting food to airborne contaminants, increasing the risk of unwanted microbial growth. Fermenting sleeves offer a more controlled environment, reducing contamination by limiting air exposure while allowing gas to escape.

- Open-bowl contamination risk - Airborne bacteria and mold spores can settle on the fermenting surface, leading to spoilage.

- Fermenting sleeve advantage - The sleeve acts as a barrier, preventing external contaminants while permitting fermentation gases to release safely.

- Prevention strategy - Regular inspection and maintaining clean equipment are critical to minimize contamination regardless of the method used.

Flavor Development Differences

The open-bowl method exposes fermenting foods to more oxygen, which can lead to a tangier and more complex flavor profile due to increased aerobic microbial activity. This technique often enhances the development of natural yeasts and bacteria, resulting in a sharper, more robust taste.

Fermenting sleeves create an anaerobic environment, promoting lactic acid bacteria growth that produces milder, more consistent flavors with subtle acidity. This controlled method reduces oxidation and contamination risks, allowing for a smoother fermentation process and refined taste outcomes.

Batch Maintenance and Care

The Open-bowl Method requires frequent monitoring and manual coverage to prevent contamination, while the Fermenting Sleeve offers a controlled environment reducing exposure to air and pests. Both methods necessitate regular checks, but the sleeve significantly simplifies batch maintenance and care.

- Open-bowl method demands daily checkups - This method leaves the batch exposed and susceptible to airborne contaminants, requiring consistent attention and manual covering.

- Fermenting Sleeve provides a sealed environment - The sleeve limits oxygen exposure and reduces the risk of external contamination, promoting a more stable fermentation process.

- Ease of cleaning favors the sleeve - The silicone material of fermenting sleeves is easier to sanitize compared to open bowls, minimizing risks during batch transitions.

Choosing the Fermenting Sleeve enhances batch consistency and reduces maintenance time in fermentation processes.

Suitability for Different Recipes

The open-bowl method offers greater flexibility for fermenting a variety of recipes, particularly those requiring easy access for mixing or adding ingredients. It is ideal for short fermentation processes and recipes that benefit from regular stirring or temperature adjustments.

The fermenting sleeve excels in maintaining consistent temperatures and humidity levels, making it suitable for long fermentation recipes such as sourdough or kimchi. It minimizes exposure to contaminants, promoting optimal microbial growth, which is crucial for delicate or slow-fermenting foods. This method ensures a controlled environment, enhancing flavor development and texture in complex ferments.

Related Important Terms

Passive Aerobic Fermentation

Open-bowl method facilitates passive aerobic fermentation by exposing the surface directly to ambient oxygen, enhancing microbial activity critical for flavor development. Fermenting sleeves provide controlled oxygen permeability, maintaining a balanced aerobic environment that reduces contamination risk while promoting consistent fermentation results.

Open-Bowl Volatilization

The open-bowl method of fermenting exposes the mixture to air, increasing volatilization rates and leading to greater aroma compound loss compared to the closed environment of fermenting sleeves. This enhanced volatilization can affect flavor profiles by dissipating key fermentative esters and organic acids more rapidly during the aerobic fermentation phase.

Microbial Drift Exposure

Open-bowl fermentation exposes the batch to increased microbial drift, raising the risk of unwanted bacteria contamination and inconsistent fermentation outcomes. Fermenting sleeves create a sealed environment that minimizes microbial drift exposure, promoting a more controlled microbial population and ensuring stable fermentation results.

Surface Area Gradient

The open-bowl method offers a larger surface area gradient, promoting faster oxygen exchange that accelerates fermentation and enhances microbial diversity. In contrast, the fermenting sleeve limits surface exposure, creating a more anaerobic environment that favors controlled fermentation and consistent flavor development.

Sleeve-Induced Anaerobiosis

The fermenting sleeve creates an anaerobic environment by tightly enclosing the fermenting vessel, limiting oxygen exposure and enhancing beneficial microbial activity for consistent fermentation results. Unlike the open-bowl method, which allows oxygen contact and increases the risk of spoilage, the sleeve-induced anaerobiosis promotes optimal lactic acid bacteria growth, improving flavor and preservation.

Barriered Fermentation Zone

The Open-bowl Method exposes the fermentation to ambient air, increasing oxygen contact that may cause inconsistent microbial activity within the barriered fermentation zone. Fermenting sleeves create a controlled barriered fermentation zone by minimizing oxygen exposure and maintaining optimal humidity, resulting in a more stable environment for microbial growth and flavor development.

Evaporative Headspace Loss

Open-bowl fermentation exhibits higher evaporative headspace loss due to its increased surface area exposure, which can lead to faster moisture evaporation and potential flavor concentration. Fermenting sleeves reduce evaporative loss by limiting air contact and maintaining humidity, thereby preserving fermentation environment stability and product consistency.

Oxygen Transfer Rate (OTR)

The Open-bowl Method facilitates a higher Oxygen Transfer Rate (OTR) due to direct exposure to ambient air, promoting faster aerobic fermentation processes. In contrast, the Fermenting Sleeve offers a controlled but reduced OTR environment, minimizing oxygen influx and favoring anaerobic microbial activity for specific fermentation profiles.

Sleeve-Cap Moisture Lock

The Fermenting Sleeve's Sleeve-Cap Moisture Lock effectively maintains optimal humidity levels, preventing air exposure and minimizing yeast contamination during fermentation. In contrast, the open-bowl method allows more airflow, which can lead to inconsistent moisture retention and higher risk of spoilage.

Open-bowl Method vs Fermenting Sleeve for fermenting. Infographic

cookingdiff.com

cookingdiff.com