Plastic containers provide a rigid, airtight environment essential for consistent fermentation, preventing contamination and preserving the flavor of fermented pets. Fermentation sleeves offer flexibility and breathability, allowing gases to escape while protecting the ferment from external contaminants. Choosing between the two depends on the desired control over oxygen exposure and ease of use during the fermentation process.

Table of Comparison

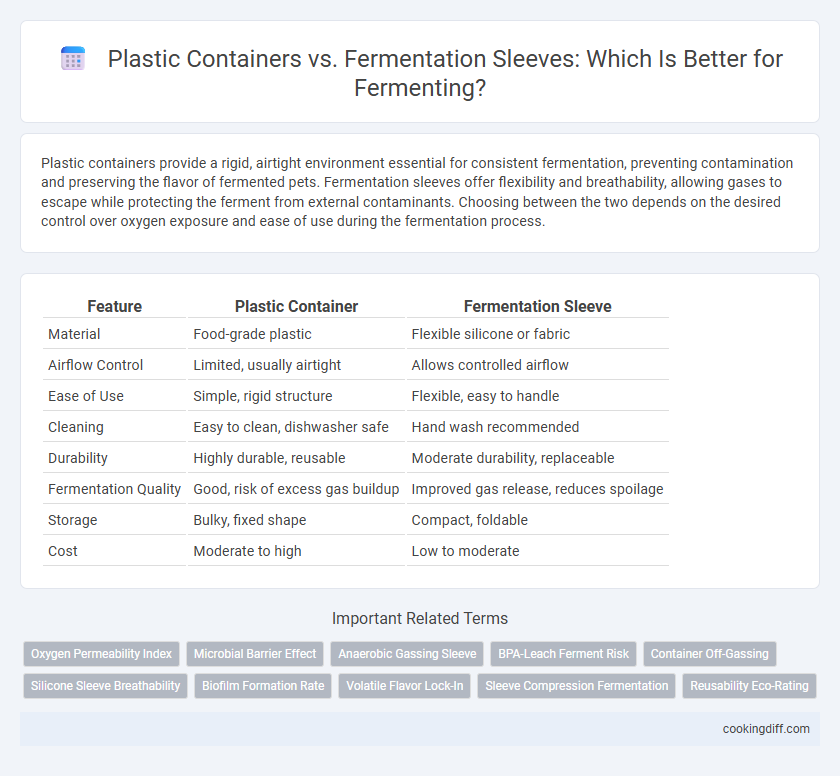

| Feature | Plastic Container | Fermentation Sleeve |

|---|---|---|

| Material | Food-grade plastic | Flexible silicone or fabric |

| Airflow Control | Limited, usually airtight | Allows controlled airflow |

| Ease of Use | Simple, rigid structure | Flexible, easy to handle |

| Cleaning | Easy to clean, dishwasher safe | Hand wash recommended |

| Durability | Highly durable, reusable | Moderate durability, replaceable |

| Fermentation Quality | Good, risk of excess gas buildup | Improved gas release, reduces spoilage |

| Storage | Bulky, fixed shape | Compact, foldable |

| Cost | Moderate to high | Low to moderate |

Introduction to Fermentation: Basics and Methods

Fermentation is a metabolic process that converts carbohydrates to alcohol or organic acids using microorganisms like yeast or bacteria under anaerobic conditions. Common fermentation methods involve different vessels, where container material can influence the fermentation environment.

Plastic containers offer lightweight, affordable options with durability and easy handling, but may lack breathability and can retain odors that affect flavor. Fermentation sleeves, typically made from fabric or breathable materials, provide controlled oxygen exposure and prevent contamination while allowing gases to escape. Choosing the appropriate vessel depends on factors like fermentation type, desired flavor profile, and ease of use.

What is a Plastic Container in Fermentation?

A plastic container in fermentation is a durable, food-grade vessel used to hold ingredients during the fermentation process, ensuring a controlled environment. These containers are popular due to their lightweight nature and resistance to breakage compared to glass or ceramic options.

- Material Safety - Plastic containers are typically made from BPA-free, food-safe plastics to prevent chemical leaching into fermenting foods.

- Ease of Use - They often feature airtight lids that help maintain anaerobic conditions essential for proper fermentation.

- Cost-Effectiveness - Plastic containers are generally more affordable and widely available, making them a practical choice for both beginners and experienced fermenters.

Understanding Fermentation Sleeves

| Plastic Container | Commonly used for fermentation due to durability and airtight seals, but may lack flexibility for gas release. |

| Fermentation Sleeve | Designed to fit over jars, allowing CO2 to escape while preventing contaminants, enhancing the natural fermentation process. |

| Advantages of Fermentation Sleeves | Provide controlled airflow, reduce risk of mold growth, and maintain an anaerobic environment essential for lactic acid bacteria activity. |

Material Safety: Plastic vs. Fermentation Sleeve

Plastic containers used for fermenting are typically made from food-grade polypropylene or polyethylene, which are BPA-free and safe for fermenting acidic foods. However, some plastics may leach chemicals over time, especially if scratched or exposed to heat, potentially affecting fermentation quality.

Fermentation sleeves are often crafted from natural, breathable fabrics like cotton, which promote air circulation and reduce condensation buildup, minimizing mold risk. Their non-toxic, chemical-free material makes them a safer alternative for long-term fermentation without the worry of harmful substances leaching into the food.

Airlock and Oxygen Control Comparison

Plastic containers often feature built-in airlocks that provide a controlled environment to minimize oxygen exposure during fermentation, essential for preventing spoilage and promoting anaerobic microbial activity. Their airtight seals help maintain consistent internal pressure, reducing the risk of contamination from external air.

Fermentation sleeves offer a flexible alternative, allowing gases produced during fermentation to escape while limiting oxygen influx through semi-permeable materials. This oxygen control supports desirable fermentation processes by balancing gas release with protection against aerobic microbes.

Ease of Cleaning and Maintenance

Plastic containers are generally easier to clean due to their smooth surfaces and non-porous material, which prevents residue buildup during fermenting. Fermentation sleeves, often made from fabric or silicone, require more careful cleaning to avoid mold and unpleasant odors.

- Plastic Container Cleaning - Smooth, non-porous surfaces allow for quick rinsing and thorough sanitization.

- Fermentation Sleeve Maintenance - Requires hand washing and drying to prevent mold growth and material degradation.

- Longevity Considerations - Plastic containers often withstand repeated cleaning cycles better than delicate fermentation sleeves.

Impact on Flavor and Quality

How does using a plastic container versus a fermentation sleeve impact the flavor and quality of fermented foods? Plastic containers can sometimes impart off-flavors or retain odors that affect the final taste, while fermentation sleeves made from inert, food-safe silicone or glass maintain natural flavors more effectively. Fermentation sleeves also provide better temperature regulation, which contributes to more consistent texture and high-quality fermentation results.

Durability and Longevity Analysis

Plastic containers offer moderate durability but can degrade over time due to exposure to acidic fermentation byproducts. Fermentation sleeves, made from heavy-duty fabric, provide enhanced longevity by resisting wear and tear more effectively during the fermenting process.

- Plastic Containers Durability - Susceptible to cracking and staining from prolonged fermentation and acidic environments.

- Fermentation Sleeves Durability - Constructed from durable, washable fabric that withstands frequent use and prevents physical damage.

- Longevity Comparison - Sleeves typically outlast plastic containers by maintaining structural integrity over multiple fermentation cycles.

The resilience of fermentation sleeves makes them a more sustainable choice for long-term fermenting needs.

Cost-Effectiveness: Sleeve vs. Plastic Container

Fermentation sleeves generally offer greater cost-effectiveness compared to plastic containers due to their reusable nature and lower initial price. Plastic containers, while durable and easy to clean, often require replacement over time, increasing long-term expenses. Investing in a fermentation sleeve can reduce waste and overall costs for both amateur and professional fermenters.

Related Important Terms

Oxygen Permeability Index

Fermentation sleeves offer a lower Oxygen Permeability Index compared to traditional plastic containers, significantly reducing oxygen exposure and promoting anaerobic fermentation crucial for preserving flavor and preventing spoilage. Plastic containers typically allow higher oxygen ingress, which can lead to inconsistent fermentation results and increased risk of mold growth.

Microbial Barrier Effect

Plastic containers often provide a solid microbial barrier due to their impermeable surfaces that prevent contamination and maintain anaerobic conditions during fermentation. Fermentation sleeves, designed from breathable materials, allow gas exchange while limiting microbial intrusion, creating a balanced environment that supports beneficial fermentation microbes without exposure to harmful pathogens.

Anaerobic Gassing Sleeve

Anaerobic gassing sleeves provide a controlled environment that inhibits oxygen exposure, promoting optimal fermentation by allowing gases like CO2 to escape without air ingress, unlike traditional plastic containers which may trap oxygen and risk spoilage. These sleeves enhance fermentation consistency and reduce contamination by maintaining an anaerobic atmosphere crucial for microorganisms such as Lactobacillus during sauerkraut or kimchi fermentation.

BPA-Leach Ferment Risk

Plastic containers used for fermenting often pose a BPA-leach risk, potentially contaminating the food with harmful chemicals. Fermentation sleeves, typically made from food-grade silicone or glass, offer a safer alternative by minimizing the exposure to BPA and preventing chemical leaching during the fermentation process.

Container Off-Gassing

Plastic containers can release volatile organic compounds (VOCs) during fermentation due to off-gassing, potentially impacting the flavor and safety of the fermented product. Fermentation sleeves, made from inert materials like silicone or glass, minimize off-gassing and create a more stable environment, preserving the purity and quality of the fermentation process.

Silicone Sleeve Breathability

Silicone fermentation sleeves offer superior breathability compared to plastic containers, allowing for optimal gas exchange while preventing contaminants from entering the fermenting environment. This breathability enhances fermentation consistency and reduces the risk of spoilage by maintaining ideal oxygen levels crucial for microbial activity.

Biofilm Formation Rate

Plastic containers generally exhibit a slower biofilm formation rate compared to fermentation sleeves due to their smoother surface and non-porous material, which inhibit microbial adhesion and colonization. Fermentation sleeves, often made of porous or flexible fabrics, promote faster biofilm development by providing increased surface area and microenvironments conducive to microbial growth during the fermenting process.

Volatile Flavor Lock-In

Plastic containers often fail to effectively lock in volatile flavors during fermentation due to their porous nature, leading to diminished aroma and taste intensity. Fermentation sleeves create a tighter seal, minimizing oxygen exposure and preserving the complex volatile compounds essential for rich, flavorful ferments.

Sleeve Compression Fermentation

Fermentation sleeves provide consistent compression, creating an anaerobic environment that enhances microbial activity and prevents mold during wild fermentation. Unlike plastic containers that often trap gases unevenly, sleeves allow for controlled airflow and weight distribution, improving flavor development and fermentation efficiency.

Plastic Container vs Fermentation Sleeve for fermenting. Infographic

cookingdiff.com

cookingdiff.com