Fermenting cheese naturally relies on ambient conditions, which can lead to inconsistent aging and flavor profiles due to varying temperature and humidity levels. Controlled fermentation chambers provide precise regulation of these factors, ensuring uniform maturation and predictable results. This technological advantage enhances the quality and safety of cheese by minimizing contamination risks and optimizing microbial activity.

Table of Comparison

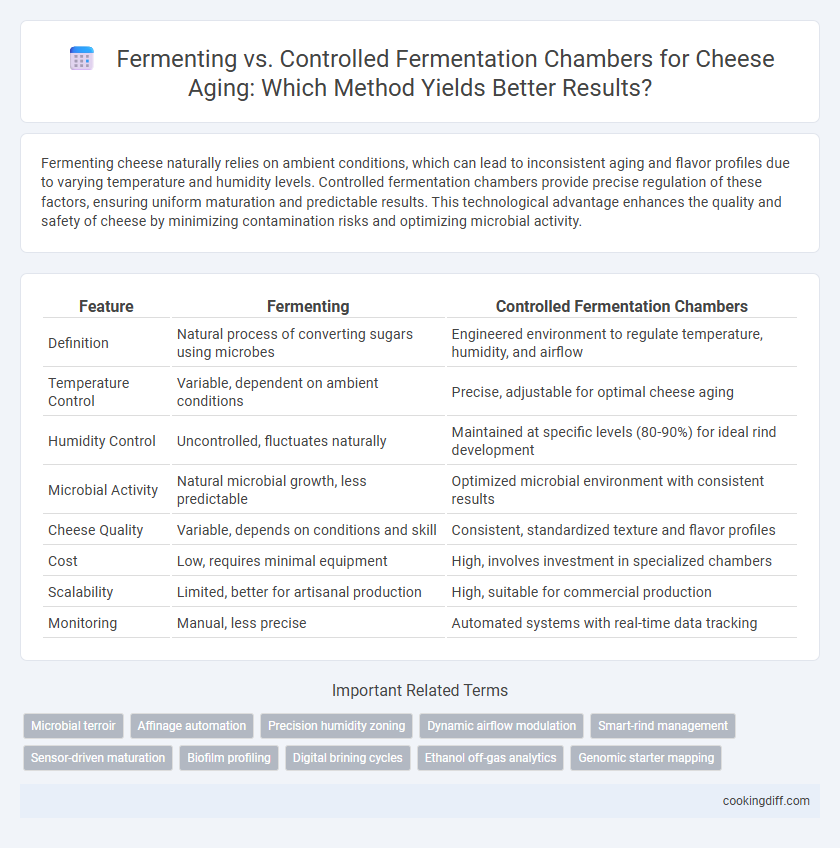

| Feature | Fermenting | Controlled Fermentation Chambers |

|---|---|---|

| Definition | Natural process of converting sugars using microbes | Engineered environment to regulate temperature, humidity, and airflow |

| Temperature Control | Variable, dependent on ambient conditions | Precise, adjustable for optimal cheese aging |

| Humidity Control | Uncontrolled, fluctuates naturally | Maintained at specific levels (80-90%) for ideal rind development |

| Microbial Activity | Natural microbial growth, less predictable | Optimized microbial environment with consistent results |

| Cheese Quality | Variable, depends on conditions and skill | Consistent, standardized texture and flavor profiles |

| Cost | Low, requires minimal equipment | High, involves investment in specialized chambers |

| Scalability | Limited, better for artisanal production | High, suitable for commercial production |

| Monitoring | Manual, less precise | Automated systems with real-time data tracking |

Introduction to Cheese Fermentation and Aging

What are the main differences between natural fermenting and controlled fermentation chambers for cheese aging? Cheese fermentation relies on specific microbial activity to develop flavors and textures during aging, which can be influenced by environmental conditions. Controlled fermentation chambers offer precise regulation of temperature, humidity, and airflow, optimizing the aging process and ensuring consistent cheese quality.

What is Natural Cheese Fermentation?

Natural cheese fermentation relies on indigenous microbes present in milk and the environment to develop flavor and texture. Unlike controlled fermentation chambers that regulate temperature and humidity precisely, natural fermentation allows spontaneous microbial activity driven by local conditions. This process enhances unique and complex cheese profiles, reflecting the terroir of the production site.

Overview of Controlled Fermentation Chambers

Controlled fermentation chambers are specially designed environments that maintain optimal temperature, humidity, and airflow to ensure consistent cheese aging. These chambers minimize contamination risks and allow precise regulation of microbial activity essential for flavor development.

Compared to traditional fermenting methods, controlled chambers offer enhanced reproducibility and scalability for artisanal and industrial cheese production. They support uniform maturation by replicating ideal fermentation conditions tailored to specific cheese varieties.

Key Differences: Traditional vs. Controlled Methods

Traditional fermenting relies on natural environmental conditions, leading to variable cheese aging outcomes. Controlled fermentation chambers maintain precise temperature and humidity levels, ensuring consistent quality in cheese production.

- Environmental Variability - Traditional methods depend on ambient conditions which can fluctuate, affecting microbial activity.

- Temperature Control - Controlled chambers regulate temperature tightly, optimizing fermentation rates for desired cheese textures.

- Humidity Management - Controlled systems maintain stable humidity, preventing spoilage and promoting uniform rind development.

Temperature and Humidity: Impact on Cheese Maturation

Temperature and humidity control are critical in cheese aging, significantly influencing flavor development and texture. Fermenting in uncontrolled environments often leads to inconsistent maturation compared to the precise conditions maintained in controlled fermentation chambers.

- Consistent Temperature - Controlled chambers maintain stable temperatures, optimizing bacterial activity and enzymatic reactions essential for uniform cheese aging.

- Humidity Regulation - Precise humidity control prevents excessive moisture loss or mold growth, ensuring ideal rind formation and internal texture.

- Quality and Safety - Controlled environments reduce contamination risk and improve reproducibility, resulting in higher quality and safer aged cheeses.

Flavor Development in Fermenting vs. Chambers

Natural fermenting relies on ambient microbes and uncontrolled environmental variables, leading to unique, complex flavor profiles in cheese due to spontaneous microbial activity. This method promotes diverse biochemical reactions that enhance depth and character in the cheese aging process.

Controlled fermentation chambers maintain precise temperature, humidity, and airflow, optimizing conditions for consistent flavor development and reducing the risk of undesirable microbial growth. This technology enables cheesemakers to replicate specific flavor outcomes with greater predictability throughout aging cycles.

Microbial Diversity: Benefits and Drawbacks

Fermenting cheese in natural environments promotes a rich microbial diversity that enhances complex flavor profiles and unique textures. Controlled fermentation chambers limit microbial diversity but provide consistent aging conditions and reduce contamination risks.

- Enhanced Flavor Complexity - Natural fermenting environments support diverse microbial communities that create distinctive cheese flavors.

- Consistency and Safety - Controlled chambers maintain stable conditions, minimizing unwanted microbial growth and ensuring product safety.

- Microbial Risk - High microbial diversity in natural fermentation can introduce spoilage organisms or pathogens if not properly managed.

Balancing microbial diversity and environmental control is essential for optimizing cheese aging outcomes.

Safety and Consistency in Cheese Production

Controlled fermentation chambers provide precise regulation of temperature and humidity, enhancing safety by minimizing the risk of harmful bacterial growth during cheese aging. Traditional fermenting methods can lead to inconsistent microbial activity, affecting both the quality and safety of the final cheese product. Utilizing controlled environments ensures consistent flavor profiles and reduces contamination risks, promoting reliable cheese production standards.

Cost, Accessibility, and Scalability Considerations

Fermenting cheese using traditional methods often incurs lower upfront costs and is accessible to small-scale producers due to minimal equipment requirements. Controlled fermentation chambers demand higher initial investment and technical knowledge but offer precise environmental regulation for consistent cheese aging.

Cost considerations highlight that fermenting without controlled chambers reduces expenses related to electricity and maintenance. Accessibility favors traditional fermentation as it allows artisan cheesemakers to operate without specialized infrastructure. Scalability is limited in traditional fermenting, whereas controlled chambers enable larger production volumes with uniform quality, making them suitable for commercial operations aiming to expand.

Related Important Terms

Microbial terroir

Fermenting cheese in natural environments cultivates a unique microbial terroir that profoundly influences flavor development, whereas controlled fermentation chambers standardize conditions to ensure consistency by precisely managing temperature, humidity, and microbial populations. Embracing microbial terroir through traditional fermenting methods enriches cheese complexity, while controlled chambers prioritize reproducibility and safety in aging processes.

Affinage automation

Affinage automation in controlled fermentation chambers enhances cheese aging by maintaining precise temperature, humidity, and airflow, ensuring consistent microbial activity and flavor development. Traditional fermenting methods lack this level of environmental control, leading to variability in texture and taste during the maturation process.

Precision humidity zoning

Precision humidity zoning in controlled fermentation chambers allows for tailored moisture levels that enhance cheese aging by promoting optimal microbial activity and rind development. Fermenting without this technology often results in inconsistent humidity, leading to uneven texture and flavor profiles in the finished cheese.

Dynamic airflow modulation

Dynamic airflow modulation in controlled fermentation chambers ensures optimal humidity and temperature levels, enhancing the texture and flavor development of aging cheese. Unlike traditional fermenting methods, these chambers provide precise environmental control, reducing spoilage risk and accelerating maturation cycles.

Smart-rind management

Smart-rind management in fermenting cheese enhances flavor development by precisely controlling microbial activity and humidity, outperforming traditional controlled fermentation chambers. Integrating IoT sensors and AI algorithms allows real-time adjustments to optimize rind formation, ensuring consistent quality and reducing spoilage during cheese aging.

Sensor-driven maturation

Sensor-driven maturation in controlled fermentation chambers enables precise monitoring and regulation of humidity, temperature, and microbial activity, optimizing cheese aging for consistent flavor and texture development. Unlike traditional fermenting methods, these chambers use real-time data analytics to adjust environmental conditions, ensuring superior quality and reduced spoilage during the maturation process.

Biofilm profiling

Biofilm profiling during fermenting reveals dynamic microbial communities that influence cheese aging, whereas controlled fermentation chambers provide precise environmental regulation to standardize biofilm development. Understanding biofilm composition and its metabolic activity in both methods enhances flavor complexity and safety in cheese maturation.

Digital brining cycles

Digital brining cycles in controlled fermentation chambers precisely regulate salt absorption and moisture in cheese aging, enhancing flavor profiles and ensuring consistent quality. Unlike traditional fermenting methods, these automated systems optimize brine concentration and timing to improve texture development and reduce contamination risks.

Ethanol off-gas analytics

Ethanol off-gas analytics provide critical insights into the fermentation process by measuring volatile organic compounds released during cheese aging, enabling precise monitoring of microbial activity and ripening stages. Controlled fermentation chambers optimize environmental parameters such as temperature and humidity, enhancing ethanol off-gas detection accuracy and ensuring consistent cheese quality through real-time data integration.

Fermenting vs Controlled fermentation chambers for cheese aging. Infographic

cookingdiff.com

cookingdiff.com