Using a fermentation sleeve with a regular mason jar enhances the fermentation process by maintaining a consistent temperature and allowing gases to escape without letting contaminants in. Regular mason jars, while airtight, can create pressure build-up that may interfere with proper fermentation. Fermentation sleeves offer a practical, reusable solution designed specifically to optimize airflow and improve fermentation results.

Table of Comparison

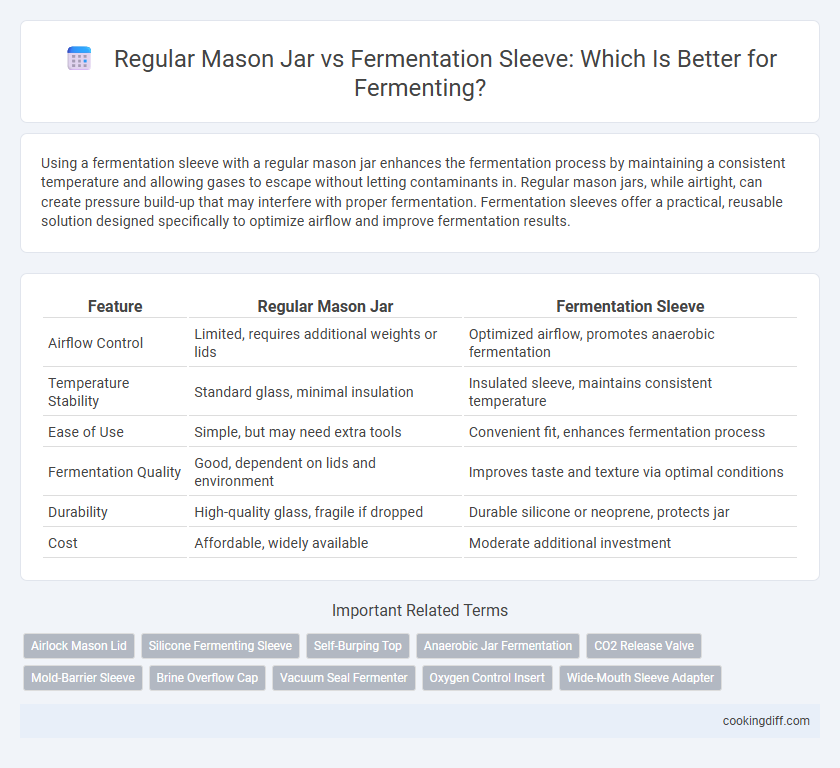

| Feature | Regular Mason Jar | Fermentation Sleeve |

|---|---|---|

| Airflow Control | Limited, requires additional weights or lids | Optimized airflow, promotes anaerobic fermentation |

| Temperature Stability | Standard glass, minimal insulation | Insulated sleeve, maintains consistent temperature |

| Ease of Use | Simple, but may need extra tools | Convenient fit, enhances fermentation process |

| Fermentation Quality | Good, dependent on lids and environment | Improves taste and texture via optimal conditions |

| Durability | High-quality glass, fragile if dropped | Durable silicone or neoprene, protects jar |

| Cost | Affordable, widely available | Moderate additional investment |

Introduction to Fermenting: Mason Jars vs Fermentation Sleeves

What are the key differences between using a regular mason jar and a fermentation sleeve for fermenting? Regular mason jars provide an affordable, airtight environment suitable for small-batch fermentation, while fermentation sleeves offer enhanced temperature control and durability. Fermentation sleeves help maintain consistent heat during the fermentation process, reducing the risk of spoilage compared to standard glass jars.

Understanding the Tools: What Are Mason Jars and Fermentation Sleeves?

Mason jars are classic glass containers with airtight lids, widely used for fermenting small batches of vegetables and beverages due to their durability and ease of sterilization. Fermentation sleeves, made from insulating materials like neoprene, are designed to maintain a consistent temperature around mason jars, optimizing the fermentation process.

While mason jars provide a sealed environment to prevent contamination and allow gas escape via specialized lids, fermentation sleeves enhance the activity of beneficial microbes by stabilizing warmth during fermentation. Both tools play complementary roles in achieving controlled fermentation environments for improved flavor and texture in fermented foods.

Airflow and Oxygen Control: Comparing Fermentation Environments

Regular mason jars provide limited airflow and oxygen control, which may lead to inconsistent fermentation results. Fermentation sleeves enhance airflow regulation and create a more stable oxygen environment, promoting optimal microbial activity.

- Limited airflow in mason jars - Mason jars' sealed lids restrict air exchange, potentially causing unwanted anaerobic conditions.

- Enhanced oxygen control with sleeves - Fermentation sleeves allow better gas exchange while minimizing oxygen exposure to prevent mold growth.

- Consistent fermentation environment - Using sleeves helps maintain stable temperature and airflow, improving flavor development and safety.

Ease of Use: Setup and Maintenance Differences

Regular mason jars offer straightforward setup with wide-mouth designs that simplify packing and cleaning, making them highly accessible for beginners. Their smooth glass surfaces prevent residue buildup, allowing for easy maintenance without specialized tools.

Fermentation sleeves provide added temperature control, but require extra steps during setup, such as fitting the sleeve securely around the jar. Maintenance can be more involved because sleeves may need washing or drying separately to avoid mold or odors.

Preventing Contamination: Mold and Yeast Management

Regular mason jars provide a tight seal that limits exposure to airborne contaminants but may trap gases, increasing the risk of mold if not burped properly. Fermentation sleeves allow gases to escape while maintaining a controlled environment, reducing yeast overgrowth and mold formation.

- Mason jar airtight seal - Prevents external contaminants but requires manual release of fermentation gases to avoid pressure build-up.

- Fermentation sleeve gas permeability - Allows carbon dioxide to escape naturally, minimizing internal moisture that promotes mold growth.

- Material antimicrobial properties - Some sleeves use materials that inhibit yeast and mold proliferation, enhancing hygiene during fermentation.

Choosing the right container system enhances mold and yeast management for safer fermentation results.

Capacity and Batch Size: Which is More Versatile?

| Regular Mason Jar | Typically available in sizes ranging from 16 oz to 64 oz, suitable for small to medium batch fermenting; limited capacity can restrict larger batch production and requires multiple jars for bigger quantities. |

| Fermentation Sleeve | Designed to fit over various jar sizes, offering flexibility in batch size management and enhancing fermentation by maintaining stable temperatures; adapts well to different capacities without needing additional containers. |

| Capacity & Versatility | Regular mason jars offer a straightforward and consistent capacity ideal for home fermenters managing a few small batches, whereas fermentation sleeves provide enhanced versatility by supporting multiple batch sizes and improving overall fermentation conditions. |

Fermentation Results: Flavor, Texture, and Consistency

Using a regular mason jar for fermenting may result in inconsistent temperature control, which can affect the flavor, texture, and overall consistency of fermented foods. Fermentation sleeves provide better insulation and temperature stability, promoting more uniform microbial activity and enhancing the development of complex, tangy flavors and crisp textures. Consistent fermentation conditions in sleeves reduce the risk of spoilage and produce a smoother, more predictable final product.

Cleaning and Reusability: Hygiene Considerations

Regular mason jars offer ease of cleaning due to their wide openings and simple glass surfaces, reducing the risk of bacteria buildup during fermentation. Fermentation sleeves, often made from silicone or other materials, require thorough cleaning to prevent mold and residue accumulation in crevices. Mason jars provide superior reusability and maintain hygienic conditions longer, making them a preferable choice for safe and consistent fermenting practices.

Cost Comparison: Affordability and Investment

Regular mason jars are widely affordable, with average prices ranging from $1 to $3 per jar, making them a cost-effective choice for beginners in fermenting. Fermentation sleeves, while more expensive initially at around $10 to $15 each, offer benefits such as temperature regulation and protection from light.

Investing in fermentation sleeves can lead to improved fermentation consistency and potentially reduce waste from spoiled batches, offering long-term savings despite the higher upfront cost. Mason jars remain the economical option for small-scale or casual fermenters focused on budget constraints. Evaluating usage frequency and fermentation goals helps determine the most cost-efficient choice between these two options.

Related Important Terms

Airlock Mason Lid

Airlock mason lids provide precise gas release during fermentation, minimizing oxygen exposure and preventing contamination compared to regular mason jars. Fermentation sleeves enhance this process by maintaining stable temperature and light protection, optimizing microbial activity for consistent, high-quality ferment results.

Silicone Fermenting Sleeve

Silicone fermenting sleeves provide a flexible, airtight seal that enhances the anaerobic environment crucial for successful fermentation, outperforming regular mason jars that may allow air intrusion. These sleeves also offer durable, reusable protection against contamination and are easy to clean, making them ideal for maintaining optimal fermentation conditions.

Self-Burping Top

Regular mason jars provide a basic airtight seal suitable for fermentation but require manual burping to release gas buildup, whereas fermentation sleeves with self-burping tops automatically vent excess carbon dioxide, reducing the risk of jar explosions and maintaining optimal anaerobic conditions. Using a self-burping top enhances safety and convenience by allowing continuous gas release while preventing oxygen exposure, essential for consistent and successful fermentation.

Anaerobic Jar Fermentation

Regular mason jars provide a simple, airtight environment suitable for anaerobic jar fermentation but may lack specialized features to maintain optimal gas release and oxygen exclusion. Fermentation sleeves enhance anaerobic conditions by allowing controlled gas escape, preventing oxygen exposure, and reducing mold risk, thereby improving fermentation quality and consistency.

CO2 Release Valve

Regular mason jars lack a built-in CO2 release valve, requiring manual burping to prevent pressure buildup during fermentation. Fermentation sleeves with integrated CO2 release valves enable automatic gas venting, ensuring safer and more consistent anaerobic conditions for optimal fermentation results.

Mold-Barrier Sleeve

A mold-barrier fermentation sleeve offers superior protection against mold growth compared to a regular mason jar by creating a controlled environment that limits oxygen exposure and moisture buildup, critical factors in preventing spoilage during fermentation. This specialized sleeve enhances anaerobic conditions essential for optimal lacto-fermentation, ensuring safer, longer-lasting ferments with consistent results.

Brine Overflow Cap

A regular mason jar lacks a dedicated brine overflow cap, increasing the risk of messy spills during active fermentation as gases build up; in contrast, a fermentation sleeve features a specialized brine overflow cap designed to safely release pressure and contain excess brine. This innovation helps maintain a clean fermentation environment, preserving anaerobic conditions essential for optimal lacto-fermentation.

Vacuum Seal Fermenter

A Vacuum Seal Fermenter enhances the fermentation process by maintaining an airtight environment, preventing oxygen exposure that can lead to spoilage, unlike regular mason jars which often lack consistent sealing. Fermentation sleeves provide insulation and protect jars but do not offer the vacuum-sealing benefits critical for preserving flavor and extending shelf life during fermenting.

Oxygen Control Insert

Regular mason jars provide airtight seals but may allow minimal oxygen exposure, potentially affecting fermentation quality and flavor development. Oxygen Control Inserts in fermentation sleeves create an anaerobic environment, enhancing preservation and promoting optimal microbial activity during the fermentation process.

Regular mason jar vs fermentation sleeve for fermenting. Infographic

cookingdiff.com

cookingdiff.com