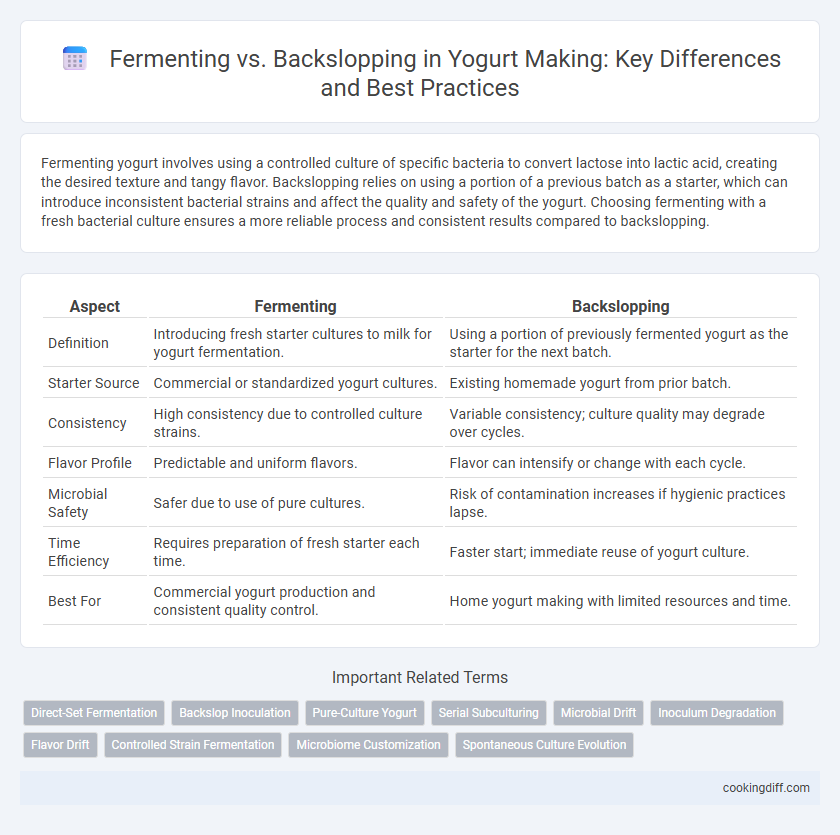

Fermenting yogurt involves using a controlled culture of specific bacteria to convert lactose into lactic acid, creating the desired texture and tangy flavor. Backslopping relies on using a portion of a previous batch as a starter, which can introduce inconsistent bacterial strains and affect the quality and safety of the yogurt. Choosing fermenting with a fresh bacterial culture ensures a more reliable process and consistent results compared to backslopping.

Table of Comparison

| Aspect | Fermenting | Backslopping |

|---|---|---|

| Definition | Introducing fresh starter cultures to milk for yogurt fermentation. | Using a portion of previously fermented yogurt as the starter for the next batch. |

| Starter Source | Commercial or standardized yogurt cultures. | Existing homemade yogurt from prior batch. |

| Consistency | High consistency due to controlled culture strains. | Variable consistency; culture quality may degrade over cycles. |

| Flavor Profile | Predictable and uniform flavors. | Flavor can intensify or change with each cycle. |

| Microbial Safety | Safer due to use of pure cultures. | Risk of contamination increases if hygienic practices lapse. |

| Time Efficiency | Requires preparation of fresh starter each time. | Faster start; immediate reuse of yogurt culture. |

| Best For | Commercial yogurt production and consistent quality control. | Home yogurt making with limited resources and time. |

Introduction to Yogurt Fermentation Methods

Yogurt fermentation involves the conversion of lactose into lactic acid by beneficial bacteria, which thickens milk and develops its tangy flavor. Two primary methods used are direct fermenting and backslopping, each influencing the yogurt's taste, texture, and microbial composition.

- Direct fermenting - Involves adding a pure starter culture of specific bacterial strains for consistent and controlled fermentation.

- Backslopping - Uses a portion of a previous batch as an inoculum, promoting natural microbial diversity but with variable outcomes.

- Microbial Dynamics - Direct fermenting offers standardized bacteria, while backslopping may enhance probiotic variety and complexity.

Understanding these methods helps in selecting the appropriate approach for desired yogurt quality and safety.

What Is Traditional Fermenting?

Traditional fermenting for yogurt making involves naturally occurring lactic acid bacteria converting milk sugars into lactic acid, creating a thick and tangy product. This process relies on ambient microbial environments without introducing a controlled starter culture.

Backslopping, by contrast, uses a portion of a previous successful batch as the starter culture to consistently inoculate new milk. This method helps maintain specific bacterial strains, ensuring product uniformity in flavor and texture.

Understanding Backslopping in Yogurt Making

Backslopping in yogurt making involves using a portion of a previous batch as a starter culture to ferment a new batch, promoting consistent flavor and texture. This traditional method differs from direct fermentation using commercial starters by relying on the natural microbial population retained in the old yogurt.

- Microbial Consistency - Backslopping maintains a stable microbial community, enhancing yogurt quality through successive batches.

- Flavor Development - Using backslopping can develop complex, richer flavors compared to single-use commercial starters.

- Risk of Contamination - Repeated backslopping requires careful hygiene to prevent unwanted microbial growth that can spoil the yogurt.

Key Differences: Fermenting vs Backslopping

| Aspect | Fermenting | Backslopping |

|---|---|---|

| Process | Involves adding a specific starter culture of bacteria to milk and allowing controlled fermentation to produce yogurt. | Uses a portion of previously fermented yogurt as the inoculum for the next batch, promoting natural culture development. |

| Consistency | Yields consistent yogurt quality due to standardized starter cultures and controlled conditions. | May result in variable yogurt texture and flavor depending on the microbial changes in the reused starter. |

| Microbial Control | Employs specific strains of Lactobacillus bulgaricus and Streptococcus thermophilus for predictable fermentation. | Relies on the mixed microbial population from the previous batch, which can evolve and affect fermentation dynamics. |

Microbial Diversity in Each Method

Fermenting yogurt using commercial starter cultures ensures a controlled microbial diversity, primarily consisting of well-defined strains like Lactobacillus bulgaricus and Streptococcus thermophilus. Backslopping, on the other hand, introduces a more variable microbial community sourced from previous batches, potentially increasing the diversity with wild or opportunistic bacteria.

Microbial diversity in backslopping can enhance flavor complexity and probiotic qualities due to the presence of multiple bacterial strains adapting to the local environment. However, this variability also poses risks of contamination and inconsistent fermentation results. Controlled fermenting offers reproducibility and safety but may lack the unique microbial interactions found in backslopped yogurt.

Impact on Yogurt Flavor and Texture

How does fermenting compare to backslopping in impacting yogurt flavor and texture? Fermenting with a controlled starter culture often results in consistent yogurt flavor and a smooth, creamy texture. Backslopping can introduce more complex flavors but risks uneven texture and potential contamination.

Health Benefits Comparison

Fermenting yogurt with pure starter cultures ensures consistent probiotic strains that support digestive health and boost immunity. Backslopping, while traditional, may introduce variable microbial populations, potentially reducing the reliability of health benefits. Studies indicate that controlled fermenting methods deliver higher concentrations of beneficial bacteria, enhancing nutrient absorption and gut flora balance.

Consistency and Reliability in Results

Fermenting yogurt using a controlled starter culture ensures consistent acidity and texture, resulting in reliable batch-to-batch quality. This method minimizes variability caused by environmental factors and microbial competition.

Backslopping relies on using a portion of previous yogurt batches, which can introduce fluctuating microbial populations, affecting consistency in flavor and firmness. Although traditional, backslopping often leads to inconsistent fermentation times and product reliability.

Safety Considerations for Home Yogurt Makers

Fermenting yogurt using a fresh, controlled starter culture reduces the risk of harmful bacterial contamination compared to backslopping, which reuses previous batches and may harbor unwanted microbes. Maintaining proper hygiene and consistent fermentation temperature is critical to ensure safety and product quality in home yogurt making.

- Use of fresh starter culture - Ensures microbial safety by introducing known, beneficial bacteria strains to the milk.

- Risks of backslopping - Increases the chance of pathogenic bacteria proliferation due to potential contamination from previous batches.

- Temperature control - Prevents growth of harmful organisms by keeping fermentation within optimal ranges (around 110degF/43degC).

Related Important Terms

Direct-Set Fermentation

Direct-set fermentation uses a precise, single-strain starter culture for consistent yogurt quality and faster production, unlike backslopping which relies on reusing previous batches, risking contamination and flavor variability. This method enhances microbial control and safety, ensuring uniform texture and taste in yogurt making.

Backslop Inoculation

Backslop inoculation in yogurt making involves using a portion of a previous batch as a starter culture, enhancing microbial consistency and fermentation speed. This method maintains the yogurt's flavor profile and texture by preserving specific bacterial strains, unlike direct fermentation with commercial starters that may yield variable results.

Pure-Culture Yogurt

Pure-culture yogurt fermentation uses specific starter strains like Lactobacillus bulgaricus and Streptococcus thermophilus to ensure consistent flavor, texture, and safety, unlike backslopping which relies on a portion of previous batches and can introduce variability or contamination. This controlled fermentation process optimizes the probiotic content and maintains high-quality standards essential for commercial and home yogurt production.

Serial Subculturing

Serial subculturing in yogurt making involves transferring a portion of a fermented batch to fresh milk to initiate fermentation, ensuring consistent microbial activity and flavor development. Backslopping relies on this method but may risk contamination and variability, whereas controlled fermenting with pure starter cultures provides more predictable and standardized yogurt quality.

Microbial Drift

Fermenting yogurt using a controlled starter culture minimizes microbial drift, ensuring consistent bacterial strains and product quality, whereas backslopping involves reusing a portion of previous batches that can introduce unpredictable microbial shifts and contamination risk. Studies show that microbial drift in backslopping may lead to altered fermentation dynamics and variability in yogurt texture and flavor.

Inoculum Degradation

Fermenting with a pure starter culture minimizes inoculum degradation by ensuring consistent microbial viability and activity during yogurt production, unlike backslopping which often leads to a decline in beneficial bacteria due to repeated use of previously fermented material. Inoculum degradation in backslopping can result in weaker fermentation performance and inconsistent yogurt quality, highlighting the importance of fresh, well-characterized inoculums for reliable yogurt fermentation.

Flavor Drift

Fermenting yogurt using a pure starter culture ensures consistent flavor profiles, while backslopping introduces flavor drift due to the accumulation of microbial diversity and metabolic byproducts over successive batches. This flavor drift can result in unpredictable taste variations, affecting yogurt quality and consumer preference.

Controlled Strain Fermentation

Controlled strain fermentation in yogurt making ensures consistent product quality by using specific, purified bacterial cultures, unlike backslopping which relies on traditional, less predictable methods of reusing previously fermented yogurt. This precision in strain selection enhances microbial stability and flavor uniformity, optimizing fermentation efficiency and food safety.

Microbiome Customization

Fermenting through direct starter cultures allows precise microbiome customization by controlling specific bacterial strains, enhancing consistency and probiotic benefits in yogurt. Backslopping relies on transferring microbes from previous batches, which may introduce microbial variability but can develop unique, site-specific microbiomes over time.

Fermenting vs Backslopping for yogurt making. Infographic

cookingdiff.com

cookingdiff.com