Enamel crocks provide a traditional, chemical-free environment ideal for natural fermentation, maintaining stable acidity but lacking precise temperature control. Temperature-controlled fermenters optimize fermentation by maintaining consistent heat levels, accelerating the process and improving reproducibility for various recipes. Choosing between the two depends on whether prioritizing authenticity and simplicity or precise control and convenience in fermenting pet foods.

Table of Comparison

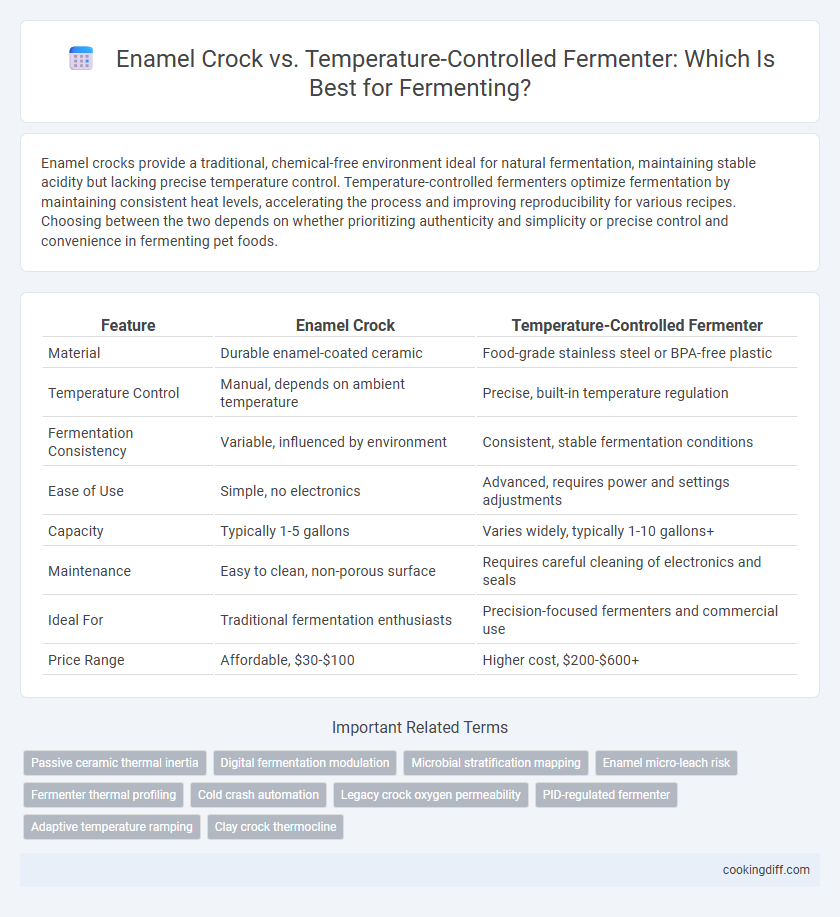

| Feature | Enamel Crock | Temperature-Controlled Fermenter |

|---|---|---|

| Material | Durable enamel-coated ceramic | Food-grade stainless steel or BPA-free plastic |

| Temperature Control | Manual, depends on ambient temperature | Precise, built-in temperature regulation |

| Fermentation Consistency | Variable, influenced by environment | Consistent, stable fermentation conditions |

| Ease of Use | Simple, no electronics | Advanced, requires power and settings adjustments |

| Capacity | Typically 1-5 gallons | Varies widely, typically 1-10 gallons+ |

| Maintenance | Easy to clean, non-porous surface | Requires careful cleaning of electronics and seals |

| Ideal For | Traditional fermentation enthusiasts | Precision-focused fermenters and commercial use |

| Price Range | Affordable, $30-$100 | Higher cost, $200-$600+ |

Introduction to Fermentation Vessel Choices

Choosing the right fermentation vessel significantly impacts the quality and consistency of fermented foods. Enamel crocks offer a traditional, non-reactive environment, while temperature-controlled fermenters provide precise temperature management for optimal fermentation conditions.

- Enamel Crocks - Durable and chemical-resistant, ideal for naturally regulating fermentation but lack precise temperature control.

- Temperature-Controlled Fermenters - Equipped with adjustable heating elements to maintain consistent temperatures, enhancing fermentation accuracy.

- Vessel Selection Impact - Proper vessel choice influences flavor development, fermentation speed, and product safety.

What Is an Enamel Crock?

An enamel crock is a traditional fermentation vessel made from ceramic coated with a smooth, non-reactive enamel surface that prevents interaction with fermenting food. Its thick walls provide natural insulation, maintaining a stable environment ideal for fermenting vegetables like sauerkraut and kimchi.

Unlike temperature-controlled fermenters that regulate heat electronically, an enamel crock relies on ambient temperature and can be paired with weights and lids to create an anaerobic environment. This simplicity makes enamel crocks durable, easy to clean, and favored for batch fermenting without precise temperature control.

Understanding Temperature-Controlled Fermenters

Temperature-controlled fermenters maintain a consistent environment between 65degF and 75degF, crucial for optimal microbial activity during fermentation. Unlike enamel crocks, they allow precise regulation of heat, reducing risks of spoilage or uneven fermentation.

Enamel crocks depend on ambient temperature and are ideal for cooler climates but lack active temperature control mechanisms. Temperature-controlled fermenters enhance product consistency, especially for fermenting kimchi, sauerkraut, and yogurt.

Material Differences: Enamel vs. Modern Tech

| Enamel Crock | Traditional ceramic material with a durable enamel coating that provides a non-reactive surface ideal for preserving the natural flavors during fermentation without absorbing odors or stains. |

| Temperature-Controlled Fermenter | Equipped with modern technology such as precise heating and cooling elements, constructed with stainless steel or BPA-free plastics that offer superior control over fermentation temperature, ensuring consistent results and faster fermenting processes. |

| Material Differences | Enamel crocks rely on passive thermal properties and chemical inertness, while temperature-controlled fermenters integrate advanced electronic components and insulated materials for optimal thermal regulation and automation in fermenting environments. |

Temperature Stability and Impact on Fermentation

Enamel crocks rely on ambient room temperature, often causing fluctuations that can slow fermentation or lead to inconsistent results. Temperature-controlled fermenters maintain a steady, optimal temperature, enhancing microbial activity and producing more reliable fermentation outcomes.

- Temperature Stability - Enamel crocks lack insulation, exposing fermenting foods to external temperature variations.

- Enhanced Microbial Growth - Controlled fermenters provide ideal warmth, accelerating fermentation by promoting beneficial bacteria.

- Consistency of Results - Steady temperatures in controlled fermenters reduce the risk of spoilage and off-flavors common with enamel crocks.

Choosing a temperature-controlled fermenter significantly improves fermentation quality by ensuring stable and precise temperature regulation.

Ease of Use: Hands-On vs. Automated Fermenting

Which option offers greater ease of use: an enamel crock or a temperature-controlled fermenter? Enamel crocks require hands-on attention, manual monitoring, and frequent adjustments to maintain proper fermentation conditions. Temperature-controlled fermenters automate the process by regulating temperature precisely, reducing the need for constant supervision and ensuring consistent results.

Cleaning and Maintenance Requirements

Enamel crocks require thorough hand washing to prevent chipping and avoid retaining odors, making regular maintenance essential. Temperature-controlled fermenters often feature removable, dishwasher-safe components that simplify cleaning and ensure consistent hygiene. Choosing between the two depends on balancing ease of cleaning with fermentation precision.

Flavor Profiles and Batch Consistency

Enamel crocks provide a natural, inert environment that gently fosters the development of complex, rich flavor profiles due to their porous surface, although they lack precise temperature regulation. This can lead to slight variations in batch consistency, as ambient temperature fluctuations impact fermentation speed and microbial activity.

Temperature-controlled fermenters offer precise thermal regulation, ensuring uniform fermentation conditions that enhance batch-to-batch consistency and reduce the risk of off-flavors. The controlled environment stabilizes microbial growth, promoting predictable and optimized flavor development. These fermenters are ideal for artisans and commercial producers aiming for reproducible, high-quality fermentations.

Cost Comparison: Upfront and Long-Term

Enamel crocks offer an affordable upfront investment but may require additional expenses for maintaining consistent fermentation temperatures. Temperature-controlled fermenters have a higher initial cost but provide precise temperature regulation, reducing the risk of spoilage and waste over time.

- Enamel crock initial cost - Typically lower, ranging from $20 to $80 depending on size and quality.

- Temperature-controlled fermenter upfront price - Generally between $150 to $300, accounting for built-in heating and cooling systems.

- Long-term cost benefits - Temperature-controlled fermenters save money by reducing batch failures and optimizing fermentation cycles, offsetting the higher initial purchase price.

Related Important Terms

Passive ceramic thermal inertia

Enamel crocks benefit from passive ceramic thermal inertia, maintaining consistent temperature by gradually absorbing and releasing heat, which supports slow, steady fermentation without electrical input. In contrast, temperature-controlled fermenters actively regulate temperature using electronic systems, offering precision but lacking the natural thermal buffering properties of ceramic materials.

Digital fermentation modulation

Digital fermentation modulation in temperature-controlled fermenters offers precise thermal regulation, enhancing microbial activity and ensuring consistent fermentation results. Enamel crocks lack this capability, resulting in variable fermentation outcomes due to fluctuating ambient temperatures.

Microbial stratification mapping

Enamel crocks provide a natural microenvironment that fosters diverse microbial stratification due to their porous surfaces and ambient temperature fluctuations, enhancing flavor complexity in fermentation. Temperature-controlled fermenters enable precise regulation of microbial growth layers, allowing for reproducible stratification mapping and consistent fermentation outcomes.

Enamel micro-leach risk

Enamel crocks, while traditional for fermenting, pose a micro-leach risk due to potential acidic degradation of the enamel surface, which can introduce harmful compounds into the ferment. Temperature-controlled fermenters offer a safer and more consistent environment by eliminating micro-leach concerns and maintaining precise fermentation conditions.

Fermenter thermal profiling

Enamel crocks offer natural insulation that helps maintain ambient temperature stability but lack precise thermal profiling compared to temperature-controlled fermenters, which provide consistent, adjustable heat to optimize microbial activity during fermentation. Temperature-controlled fermenters utilize digital controls and sensors to maintain exact temperature ranges critical for reproducible fermentation results and enhanced flavor development.

Cold crash automation

Enamel crocks offer traditional, natural fermentation benefits but lack precise temperature control and cold crash automation, which can lead to inconsistent results. Temperature-controlled fermenters with integrated cold crash features ensure optimal microbial activity by maintaining stable fermentation temperatures and automating rapid cooling to halt fermentation precisely.

Legacy crock oxygen permeability

Enamel crocks, known for their legacy craftsmanship, allow minimal oxygen permeability which fosters an ideal anaerobic environment essential for authentic fermentation, whereas temperature-controlled fermenters provide precise thermal regulation but often lack the natural breathability crucial for traditional microbial activity. This oxygen permeability in enamel crocks supports beneficial bacteria growth and enhances flavor complexity during fermentation processes.

PID-regulated fermenter

Enamel crocks provide a traditional, non-electric method for fermenting with natural temperature fluctuations that can influence microbial activity, whereas a PID-regulated temperature-controlled fermenter ensures precise, consistent temperature management critical for optimal bacterial growth and flavor development. The PID controller continuously adjusts heating elements based on real-time temperature feedback, maintaining ideal fermentation conditions and reducing the risk of spoilage or off-flavors compared to enamel crocks.

Adaptive temperature ramping

Enamel crocks provide a traditional fermentation environment but lack adaptive temperature ramping control, resulting in less precise temperature adjustments during fermentation. Temperature-controlled fermenters enable adaptive temperature ramping, optimizing microbial activity and flavor development by automatically adjusting temperatures throughout the fermentation process.

Enamel crock vs temperature-controlled fermenter for fermenting. Infographic

cookingdiff.com

cookingdiff.com