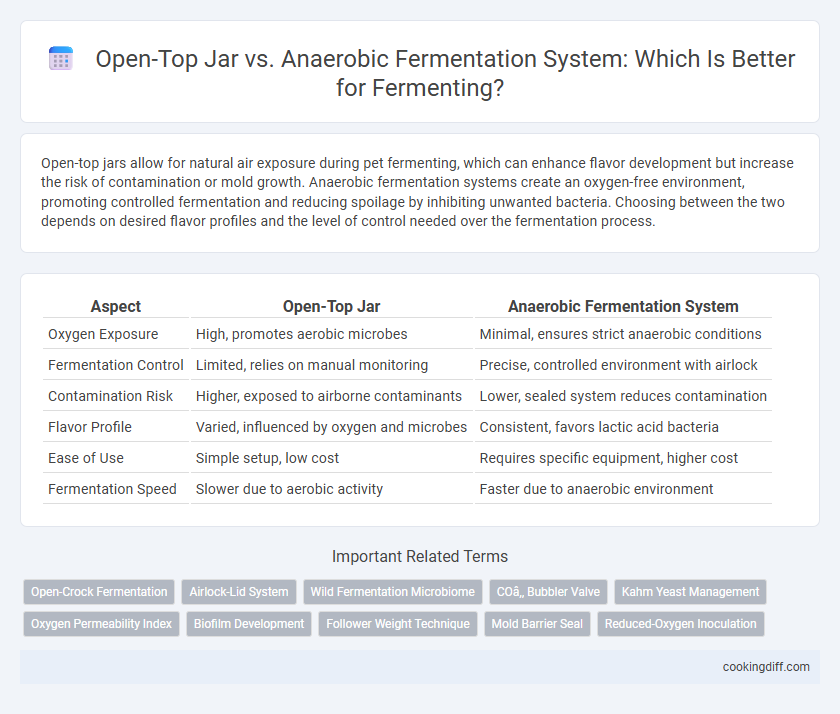

Open-top jars allow for natural air exposure during pet fermenting, which can enhance flavor development but increase the risk of contamination or mold growth. Anaerobic fermentation systems create an oxygen-free environment, promoting controlled fermentation and reducing spoilage by inhibiting unwanted bacteria. Choosing between the two depends on desired flavor profiles and the level of control needed over the fermentation process.

Table of Comparison

| Aspect | Open-Top Jar | Anaerobic Fermentation System |

|---|---|---|

| Oxygen Exposure | High, promotes aerobic microbes | Minimal, ensures strict anaerobic conditions |

| Fermentation Control | Limited, relies on manual monitoring | Precise, controlled environment with airlock |

| Contamination Risk | Higher, exposed to airborne contaminants | Lower, sealed system reduces contamination |

| Flavor Profile | Varied, influenced by oxygen and microbes | Consistent, favors lactic acid bacteria |

| Ease of Use | Simple setup, low cost | Requires specific equipment, higher cost |

| Fermentation Speed | Slower due to aerobic activity | Faster due to anaerobic environment |

Introduction to Fermentation Methods

Open-top jars provide easy access and oxygen exposure, promoting aerobic fermentation ideal for vegetables like sauerkraut. Anaerobic fermentation systems create an oxygen-free environment, reducing the risk of mold and ensuring consistent fermentation for products like kimchi. Choosing the right method depends on the desired flavor profile and fermentation control.

What Is an Open-Top Jar Fermentation?

An open-top jar fermentation involves using a jar without a sealed lid, allowing natural airflow during the fermentation process. This method is often preferred for fermenting vegetables like sauerkraut and kimchi, where exposure to oxygen can influence flavor and texture.

- Airflow Exposure - The open-top jar allows oxygen to interact with the fermenting food, impacting microbial activity and flavor development.

- Ease of Use - Open-top jars are simple to use and monitor, making it easy to check fermentation progress.

- Risk of Contamination - The lack of an airtight seal can increase the risk of mold or unwanted bacteria entering the ferment.

Understanding Anaerobic Fermentation Systems

Open-top jars allow air exposure during fermentation, increasing the risk of mold growth and oxidation, whereas anaerobic fermentation systems create an oxygen-free environment that preserves beneficial microbes. Understanding anaerobic fermentation systems is crucial for achieving consistent, high-quality fermentations by minimizing contamination and controlling gas release effectively.

These systems typically include airlocks or weighted lids that maintain anaerobic conditions while allowing carbon dioxide to escape, which prevents the buildup of pressure. The controlled environment promotes the growth of lactic acid bacteria essential for preserving vegetables and developing complex flavors. Mastery of anaerobic fermentation techniques enhances safety, texture, and nutritional value in fermented products.

Oxygen Exposure: Risks and Benefits

Open-top jars allow direct oxygen exposure, which can promote aerobic yeast activity but also increase the risk of mold growth during fermentation. Anaerobic fermentation systems create an oxygen-free environment, reducing spoilage risk and encouraging beneficial anaerobic bacteria development.

Oxygen exposure in open-top jars may lead to inconsistent fermentation results due to fluctuating air contact. In contrast, anaerobic systems provide a controlled environment that enhances flavor complexity and preserves the ferment's safety and quality.

Flavor Differences: Open-Top vs Anaerobic Fermentation

Open-top jars allow oxygen exposure which promotes the growth of wild yeasts and aerobic bacteria, resulting in complex, tangy flavors with slight surface mold development that adds depth. Anaerobic fermentation systems create oxygen-free environments that favor lactic acid bacteria, producing cleaner, more consistent sour profiles with fewer off-flavors.

The flavor in open-top fermentation often varies due to fluctuating oxygen levels and microbial diversity, contributing to rustic, robust taste notes. In contrast, anaerobic systems maintain a stable, controlled environment that enhances subtle umami and preserves delicate aromatic compounds.

Safety Concerns and Contamination Risks

Which fermentation method offers better protection against safety concerns and contamination risks? Open-top jars expose fermenting foods to air, increasing the chance of mold growth and unwanted bacteria. Anaerobic fermentation systems create a sealed environment that limits oxygen exposure, significantly reducing the risk of contamination and ensuring safer fermentation.

Ease of Use and Maintenance

| Open-top Jar | Simple design allows easy access for stirring and sampling, requiring minimal cleaning due to fewer parts. Regular manual monitoring is necessary to avoid mold or spoilage. Maintains airflow which can increase maintenance frequency but simplifies straightforward use. |

| Anaerobic Fermentation System | Sealed environment reduces contamination risk and limits maintenance by controlling oxygen exposure. Often includes airlocks or valves that need periodic cleaning to ensure proper function. Slightly more complex initial setup but enhances ease of use over longer fermentation periods. |

Cost Comparison: Initial Investment and Upkeep

Open-top jars require a minimal initial investment, usually under $10, making them the most cost-effective choice for home fermenters. Anaerobic fermentation systems involve higher upfront costs, often ranging from $30 to $100, but they reduce spoilage and maintenance expenses due to controlled environments. Over time, the low upkeep of anaerobic systems can offset initial costs, while open-top jars may incur occasional expenses from mold cleanup and fermentation failures.

Ideal Uses for Each Fermentation Method

Open-top jars are ideal for fermenting vegetables that benefit from exposure to air, like sauerkraut and kimchi, while anaerobic fermentation systems excel in environments where oxygen exclusion is crucial to prevent mold and spoilage, such as in yogurt or sourdough starters.

- Open-top jars - Best suited for small-batch vegetable ferments that require natural gas escape and air contact.

- Anaerobic systems - Designed to maintain oxygen-free environments ideal for sensitive ferments needing consistent conditions.

- Ease of monitoring - Open-top jars allow visual inspection and skimming while anaerobic systems often have airlocks to control gases without opening.

Choosing the proper fermentation setup depends on the product type and desired control over oxygen exposure.

Related Important Terms

Open-Crock Fermentation

Open-Crock fermentation utilizes an open-top jar design that allows gases to escape naturally while maintaining submersion of the fermenting food, which supports the growth of beneficial lactobacilli and prevents mold. Unlike anaerobic fermentation systems that require airtight seals and airlocks, open-top crocks offer a traditional, low-maintenance method ideal for fermenting vegetables with consistent temperature and moisture control.

Airlock-Lid System

The Airlock-Lid System in anaerobic fermentation creates a sealed environment that prevents oxygen exposure, essential for beneficial lactic acid bacteria growth and preventing mold contamination. Unlike open-top jars, this method maintains consistent anaerobic conditions, enhancing fermentation stability and flavor development.

Wild Fermentation Microbiome

Open-top jars facilitate exposure to ambient wild fermentation microbiomes, promoting diverse microbial colonization but also increasing risk of contamination and inconsistent anaerobic conditions. Anaerobic fermentation systems maintain controlled, oxygen-free environments that optimize the growth of specific anaerobic microbes essential for stable, reproducible wild fermentation processes.

CO₂ Bubbler Valve

Open-top jars allow CO2 to escape freely during fermentation but increase oxygen exposure, potentially leading to spoilage, whereas anaerobic fermentation systems with CO2 bubbler valves create a controlled environment that efficiently releases gas while preventing oxygen intrusion. The CO2 bubbler valve maintains an optimal anaerobic atmosphere, enhancing microbial activity and promoting consistent, high-quality fermentation results.

Kahm Yeast Management

Open-top jars expose fermenting foods to more oxygen, which increases the likelihood of Kahm yeast growth on the surface, requiring frequent skimming and monitoring to prevent off-flavors. Anaerobic fermentation systems minimize oxygen exposure, creating an environment less conducive to Kahm yeast formation and promoting cleaner, more consistent fermentation results.

Oxygen Permeability Index

Open-top jars have a high Oxygen Permeability Index, allowing more oxygen exposure which can lead to surface mold during fermentation. Anaerobic fermentation systems maintain a low Oxygen Permeability Index, preventing oxygen contact and promoting optimal growth of anaerobic bacteria for consistent fermentation results.

Biofilm Development

Open-top jars promote biofilm development by allowing oxygen exposure, which supports the growth of aerobic microorganisms essential for initial fermentation stages. Anaerobic fermentation systems inhibit biofilm formation by maintaining oxygen-free environments, favoring anaerobic bacteria that produce lactic acid and reduce surface microbial growth.

Follower Weight Technique

Open-top jars facilitate the Follower Weight Technique by allowing easy placement of weights directly on the fermenting vegetables, promoting consistent submersion and reducing oxygen exposure. In contrast, anaerobic fermentation systems often incorporate built-in airlocks and weights, ensuring a controlled environment that minimizes contamination risk while maintaining ideal anaerobic conditions.

Mold Barrier Seal

Open-top jars allow air exchange which may increase mold growth, while anaerobic fermentation systems use a mold barrier seal that creates an oxygen-free environment to prevent mold development. The mold barrier seal is critical for maintaining anaerobic conditions, enhancing fermentation safety and product quality by inhibiting aerobic spoilage organisms.

Open-top jar vs anaerobic fermentation system for fermenting. Infographic

cookingdiff.com

cookingdiff.com