Traditional brining vessels rely on submerging ingredients in saltwater to create an environment that encourages natural fermentation through lactobacillus activity. Anaerobic fermenters provide a controlled environment by eliminating oxygen, reducing the risk of spoilage and promoting consistent fermentation results. Selecting between these methods depends on desired flavor complexity and ease of use, with anaerobic fermenters often offering more precision and reduced maintenance.

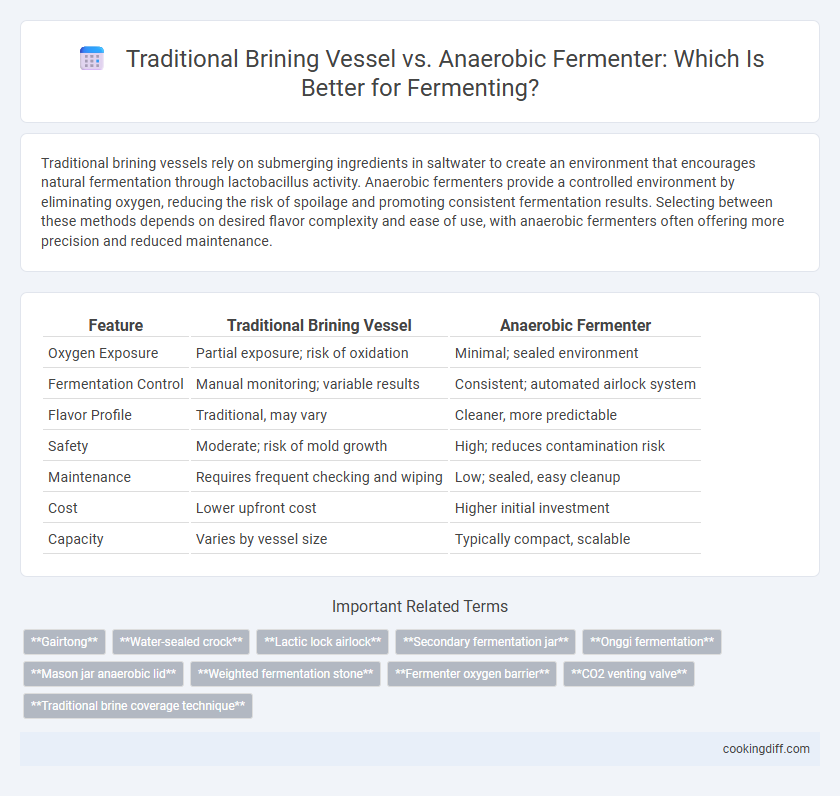

Table of Comparison

| Feature | Traditional Brining Vessel | Anaerobic Fermenter |

|---|---|---|

| Oxygen Exposure | Partial exposure; risk of oxidation | Minimal; sealed environment |

| Fermentation Control | Manual monitoring; variable results | Consistent; automated airlock system |

| Flavor Profile | Traditional, may vary | Cleaner, more predictable |

| Safety | Moderate; risk of mold growth | High; reduces contamination risk |

| Maintenance | Requires frequent checking and wiping | Low; sealed, easy cleanup |

| Cost | Lower upfront cost | Higher initial investment |

| Capacity | Varies by vessel size | Typically compact, scalable |

Introduction to Fermentation Methods

| Traditional Brining Vessel | Utilizes open or covered containers, often ceramic or glass, allowing natural microbial activity through saltwater solution for fermentation. |

| Anaerobic Fermenter | Employs air-tight, specialized vessels designed to create oxygen-free environments, optimizing lactic acid bacteria growth and preventing spoilage. |

| Comparison | Traditional brining vessels support slow, natural fermentation processes whereas anaerobic fermenters provide consistent temperature control and oxygen exclusion, enhancing flavor and safety. |

Understanding Traditional Brining Vessels

Traditional brining vessels have been used for centuries to ferment vegetables by submerging them in saltwater, creating an environment favorable to beneficial lactic acid bacteria. These vessels rely on natural anaerobic conditions, achieved by weight and salt concentration, to inhibit spoilage organisms and enhance flavor development.

- Material Composition - Traditional brining vessels are typically made from ceramic, stoneware, or food-grade plastic, ensuring durability and non-reactivity with acidic fermentation.

- Natural Anaerobic Environment - The weight applied on the vegetables and the sealed vessel design allow fermentation to proceed without oxygen, preserving nutrients and texture.

- Microbial Control - Salt concentrations between 2-5% in the brine selectively promote lactic acid bacteria growth while preventing harmful microbes from proliferating during fermentation.

What is an Anaerobic Fermenter?

An anaerobic fermenter is a sealed container designed to create an oxygen-free environment ideal for fermenting vegetables and other foods. Unlike traditional brining vessels that rely on the natural displacement of air, anaerobic fermenters use airtight lids and airlocks to prevent oxygen exposure, reducing the risk of spoilage and mold growth. This controlled environment enhances lactic acid bacteria activity, resulting in more consistent and reliable fermentation outcomes.

Historical Context: Brining Vessels Across Cultures

Traditional brining vessels have been integral to preserving foods in diverse cultures for centuries, often crafted from natural materials like clay or wood. Anaerobic fermenters modernize this practice by creating controlled oxygen-free environments that enhance microbial activity and improve fermentation consistency.

- Traditional brining vessels - Used worldwide, these containers rely on saltwater to inhibit spoilage and foster lactic acid fermentation, with designs reflecting regional resources and customs.

- Anaerobic fermenters - Engineered to maintain strict oxygen-free conditions, they optimize fermentation rates and reduce contamination risks with modern materials and airtight seals.

- Historical significance - Brining methods reveal cultural exchanges and adaptation of preservation techniques, illustrating the evolution from rudimentary to scientifically informed fermentation tools.

Oxygen Exposure: Key Differences in Fermentation

Traditional brining vessels allow limited oxygen exposure, which can encourage the growth of aerobic microbes and affect fermentation outcomes. Anaerobic fermenters, designed to exclude oxygen completely, create an ideal environment for lactic acid bacteria, promoting consistent fermentation.

Oxygen exposure in brining vessels may lead to surface spoilage or mold development, impacting flavor and safety. In contrast, anaerobic fermenters minimize these risks by maintaining an oxygen-free environment, resulting in more controlled and reliable fermentation processes.

Flavor Development: Traditional vs. Anaerobic

Traditional brining vessels expose fermenting foods to natural air flow, promoting the growth of diverse microbial populations that contribute to complex, tangy flavor profiles. Anaerobic fermenters create an oxygen-free environment, favoring lactic acid bacteria that result in a cleaner, milder taste.

Flavor development in traditional brining vessels relies on spontaneous fermentation, often producing richer and more varied aromas due to micro-oxygenation. Anaerobic fermenters maintain consistent conditions that enhance the dominance of desirable bacteria, ensuring predictable sourness and preserving delicate flavors. The choice between the two directly influences the depth and character of fermented products.

Safety and Risk of Contamination

Traditional brining vessels, often made from ceramic or wood, rely on natural airlocks but can expose fermenting foods to potential contamination due to oxygen and wild microbes. Anaerobic fermenters utilize sealed systems with one-way valves that effectively prevent air ingress, significantly reducing the risk of unwanted bacterial growth and spoilage. The controlled environment of anaerobic fermenters enhances safety by maintaining consistent anaerobic conditions critical for successful fermentation.

Ease of Use and Maintenance

Traditional brining vessels are simple to use and require minimal setup, relying on weighted lids to keep produce submerged in the brine. They often need regular monitoring to prevent mold and maintain proper fermentation conditions.

Anaerobic fermenters feature airlock systems that reduce the need for frequent checking by preventing oxygen exposure automatically. Maintenance involves occasional cleaning of seals and airlocks, which simplifies long-term care compared to traditional vessels.

Cost and Accessibility

Traditional brining vessels are generally more cost-effective and widely accessible compared to specialized anaerobic fermenters, which often require a higher initial investment. Accessibility in local markets and simplicity in design make traditional vessels a preferred choice for beginners and small-scale fermenters.

- Lower upfront cost - Traditional brining vessels can be sourced inexpensively from kitchenware stores or repurposed containers.

- Ease of availability - They are widely available in most regions without the need for specialized suppliers.

- Simple maintenance - Traditional vessels require minimal upkeep, reducing ongoing expenses.

Anaerobic fermenters, while more expensive, offer precise control that may justify the cost for advanced fermentation projects.

Related Important Terms

Gairtong

Gairtong offers an advanced anaerobic fermenter designed to optimize fermentation by maintaining strict oxygen-free conditions, which enhances microbial activity and flavor development compared to traditional brining vessels. This innovative system reduces contamination risk and accelerates the fermenting process, resulting in consistent, high-quality fermented products.

Water-sealed crock

Water-sealed crocks, a traditional brining vessel, create an anaerobic environment by trapping gases within a water moat, effectively preventing oxygen from spoiling the ferment. This method enhances lactic acid bacteria growth, producing crisp, flavorful ferments while minimizing mold risk compared to other anaerobic fermenters with artificial seals.

Lactic lock airlock

A lactic lock airlock in traditional brining vessels ensures consistent exclusion of oxygen by allowing gas to escape while preventing air entry, crucial for optimal lactic acid fermentation. Anaerobic fermenters equipped with advanced lactic lock airlocks provide enhanced airtight sealing, minimizing contamination risk and promoting faster, more controlled fermentation processes.

Secondary fermentation jar

Secondary fermentation jars in traditional brining vessels often rely on natural anaerobic conditions created by submerging vegetables in salted water, promoting lactic acid bacteria growth. Anaerobic fermenters enhance this process by providing airtight seals and airlocks, preventing oxygen exposure and contamination, resulting in more consistent and controlled fermentation outcomes.

Onggi fermentation

Onggi fermentation utilizes traditional Korean earthenware vessels known for their porous structure, promoting natural air exchange to enhance microbial activity during the brining process. Unlike sealed anaerobic fermenters, the Onggi's unique permeability allows beneficial aerobic and anaerobic microbes to coexist, resulting in complex flavors and optimal fermentation of kimchi and fermented soy products.

Mason jar anaerobic lid

The Mason jar anaerobic lid creates an oxygen-free environment essential for optimal lactic acid fermentation, preventing mold growth typical in traditional brining vessels. Its airtight seal and built-in airlock design allow gas to escape while keeping harmful oxygen out, enhancing both safety and flavor development in fermented vegetables.

Weighted fermentation stone

A weighted fermentation stone provides consistent pressure on fermenting vegetables by keeping them submerged under brine, essential in traditional brining vessels to prevent mold and ensure even fermentation. Anaerobic fermenters often incorporate integrated weighted stones or airlock lids that maintain an oxygen-free environment, optimizing microbial activity and reducing surface spoilage compared to open traditional vessels.

Fermenter oxygen barrier

Traditional brining vessels typically allow some oxygen exposure which can cause surface mold and slower fermentation, while anaerobic fermenters feature airtight seals and oxygen barrier systems that create an oxygen-free environment, accelerating lacto-fermentation and preserving flavor integrity. The oxygen barrier in anaerobic fermenters prevents aerobic bacteria growth, ensuring a consistent, safe, and high-quality fermentation process.

CO2 venting valve

Traditional brining vessels often lack a dedicated CO2 venting valve, leading to potential pressure buildup and the need for manual burping to release gas during fermentation. Anaerobic fermenters feature integrated CO2 venting valves that automatically release excess carbon dioxide, maintaining optimal pressure and preventing oxidation or spoilage.

Traditional brining vessel vs Anaerobic fermenter for fermenting. Infographic

cookingdiff.com

cookingdiff.com