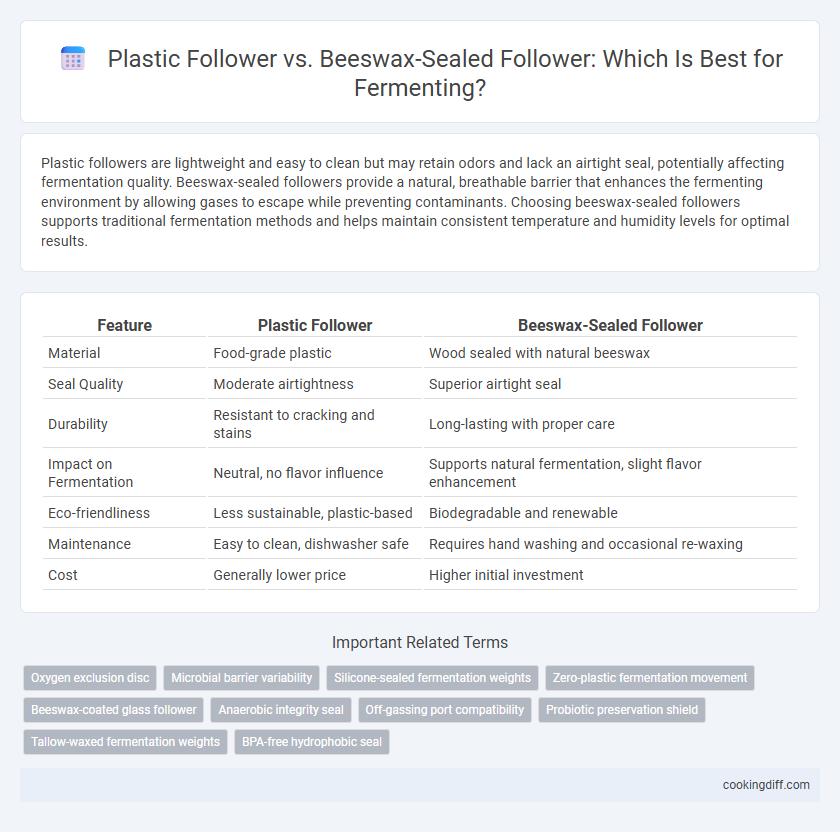

Plastic followers are lightweight and easy to clean but may retain odors and lack an airtight seal, potentially affecting fermentation quality. Beeswax-sealed followers provide a natural, breathable barrier that enhances the fermenting environment by allowing gases to escape while preventing contaminants. Choosing beeswax-sealed followers supports traditional fermentation methods and helps maintain consistent temperature and humidity levels for optimal results.

Table of Comparison

| Feature | Plastic Follower | Beeswax-Sealed Follower |

|---|---|---|

| Material | Food-grade plastic | Wood sealed with natural beeswax |

| Seal Quality | Moderate airtightness | Superior airtight seal |

| Durability | Resistant to cracking and stains | Long-lasting with proper care |

| Impact on Fermentation | Neutral, no flavor influence | Supports natural fermentation, slight flavor enhancement |

| Eco-friendliness | Less sustainable, plastic-based | Biodegradable and renewable |

| Maintenance | Easy to clean, dishwasher safe | Requires hand washing and occasional re-waxing |

| Cost | Generally lower price | Higher initial investment |

Introduction to Follower Types in Fermentation

What are the key differences between plastic followers and beeswax-sealed followers in fermentation? Plastic followers offer affordability and ease of cleaning, making them popular among beginners. Beeswax-sealed followers provide natural antimicrobial properties and create an airtight seal that enhances fermentation quality.

What Is a Plastic Follower?

A plastic follower is a lightweight tool used in fermentation crocks to keep vegetables submerged under brine, preventing mold growth and ensuring even fermentation. Made from food-grade plastic, it is non-reactive and easy to clean, making it a popular choice among home fermenters. Unlike beeswax-sealed followers, plastic followers do not create an airtight seal but provide consistent pressure to maintain anaerobic conditions during fermentation.

What Is a Beeswax-Sealed Follower?

A beeswax-sealed follower features a layer of natural beeswax around its edges to create an airtight seal during fermentation. This seal prevents exposure to oxygen, minimizing the risk of mold and spoilage while allowing gases to escape.

- Natural airtight seal - Beeswax forms a protective barrier that limits oxygen entry into the fermentation vessel.

- Prevents mold growth - The wax coating inhibits mold and unwanted microbial contamination on the fermenting surface.

- Traditional material - Beeswax is a sustainable and eco-friendly option favored in artisanal fermenting practices.

Air Exclusion: Plastic vs Beeswax-Sealed Followers

Plastic followers provide a tight fit that helps limit oxygen exposure during fermentation but may not create an airtight seal. Beeswax-sealed followers form a natural barrier that effectively excludes air, reducing oxidation risks and preserving microbial activity.

- Plastic followers fit snugly - Creating a physical barrier that restricts air entry but may allow minimal oxygen penetration over time.

- Beeswax sealing forms an airtight layer - Preventing oxygen from reaching the ferment and protecting it from spoilage.

- Air exclusion improves fermentation quality - Limiting aerobic microbial growth and enhancing flavor development.

Beeswax-sealed followers generally offer superior air exclusion, benefiting long-term ferment stability.

Material Safety and Chemical Interactions

Plastic followers used in fermenting are often made from food-grade polyethylene, which is generally safe but can potentially leach chemicals such as BPA if not properly certified. Beeswax-sealed followers provide a natural, non-toxic barrier that minimizes chemical interactions with fermenting contents and enhances anaerobic conditions. Choosing beeswax-sealed followers reduces the risk of synthetic chemical contamination, promoting safer and more natural fermentation processes.

Ease of Cleaning and Reusability Comparison

Plastic followers offer a smooth surface that resists staining and odors, making them easier to clean after fermenting. Their durability allows for repeated use without degradation, ensuring long-term reusability in fermentation processes.

Beeswax-sealed followers, while eco-friendly and natural, can retain residues that complicate cleaning and may require specialized care to preserve the wax coating. Their reusability depends on maintaining the beeswax seal, which can wear off over time, reducing effectiveness and necessitating periodic resealing.

Impact on Fermentation Flavor and Quality

Plastic followers can sometimes impart off-flavors to fermenting products due to their potential to harbor bacteria and chemicals, which may negatively affect the fermentation flavor and quality. Beeswax-sealed followers create an airtight seal that preserves the natural fermentation process, enhancing the final taste and maintaining product integrity.

Beeswax acts as a natural barrier against oxygen and contaminants, supporting consistent fermentation by maintaining an anaerobic environment. This reduces the risk of spoilage and promotes the development of complex, desirable flavors in the fermented goods. In contrast, plastic followers may degrade over time, weakening their effectiveness and potentially compromising fermentation quality.

Mold and Contaminant Prevention

| Plastic Follower | Plastic followers are non-porous, reducing the risk of mold growth by creating a barrier against air and contaminants during fermentation. They are easy to clean and sanitize, preventing bacterial contamination effectively. |

| Beeswax-Sealed Follower | Beeswax-sealed followers provide a natural, breathable seal that helps minimize mold formation while allowing gases to escape during fermentation. The antimicrobial properties of beeswax contribute to contaminant prevention but may require more frequent monitoring and maintenance. |

Sustainability and Environmental Considerations

Beeswax-sealed followers offer a biodegradable and renewable alternative to plastic followers, significantly reducing landfill waste. Using beeswax in fermentation tools supports sustainability by minimizing reliance on petrochemical-based materials and enhancing compostability.

- Plastic followers create non-biodegradable waste - They persist in the environment for centuries, contributing to pollution and ecosystem harm.

- Beeswax-sealed followers use natural materials - They are compostable and reduce carbon footprint through renewable sourcing.

- Sustainability impact - Beeswax followers promote eco-friendly fermentation practices aligned with green living values.

Related Important Terms

Oxygen exclusion disc

The oxygen exclusion disc in beeswax-sealed followers provides a natural, breathable barrier that effectively limits oxygen exposure while allowing carbon dioxide to escape during fermentation, enhancing preservation and flavor. In contrast, plastic followers often create a tighter, less permeable seal that can trap excess gases, potentially leading to unwanted pressure buildup and off-flavors.

Microbial barrier variability

Plastic followers used in fermenting often provide inconsistent microbial barriers due to potential porosity and chemical leaching, increasing contamination risks. Beeswax-sealed followers create a more reliable microbial barrier by leveraging beeswax's natural antimicrobial properties, enhancing fermentation safety and product quality.

Silicone-sealed fermentation weights

Silicone-sealed fermentation weights provide an airtight, non-reactive barrier that prevents spoilage by limiting oxygen exposure, outperforming plastic followers which can harbor bacteria and degrade over time. Beeswax-sealed followers offer natural antimicrobial properties but require more maintenance and can introduce unwanted flavors, making silicone-sealed weights a more durable and hygienic choice for consistent fermentation results.

Zero-plastic fermentation movement

Beeswax-sealed followers align with the Zero-plastic fermentation movement by eliminating plastic contamination during fermentation, promoting an eco-friendly and non-toxic environment crucial for preserving beneficial microorganisms. Unlike plastic followers that may leach harmful chemicals, beeswax seals offer a natural, biodegradable alternative enhancing the purity and sustainability of fermented foods.

Beeswax-coated glass follower

Beeswax-coated glass followers for fermenting provide a natural, non-toxic seal that enhances airlock effectiveness and prevents contamination better than plastic alternatives. The breathable yet protective beeswax layer maintains an optimal anaerobic environment, preserving flavor and promoting consistent fermentation results.

Anaerobic integrity seal

Plastic followers provide a durable, airtight barrier that effectively maintains anaerobic conditions essential for optimal fermentation, while beeswax-sealed followers offer a natural, mold-resistant seal that enhances anaerobic integrity by preventing oxygen infiltration. Maintaining a reliable anaerobic seal with either method minimizes exposure to oxygen, reducing spoilage risks and promoting consistent fermentation quality.

Off-gassing port compatibility

Plastic followers typically feature built-in off-gassing ports that efficiently release fermentation gases, reducing pressure buildup inside the vessel. Beeswax-sealed followers lack integrated venting mechanisms, making them less compatible with off-gassing ports and potentially increasing the risk of anaerobic pressure during fermentation.

Probiotic preservation shield

Beeswax-sealed followers provide a stronger probiotic preservation shield by creating a natural, breathable barrier that maintains optimal anaerobic conditions during fermentation, reducing contamination risks. Plastic followers often lack this breathable quality, which can lead to moisture buildup and diminished probiotic viability over time.

Tallow-waxed fermentation weights

Tallow-waxed fermentation weights provide a natural, breathable barrier that supports anaerobic fermentation while preventing contamination, outperforming plastic followers that may trap moisture and hinder airflow. Beeswax sealing enhances the protective layer, ensuring optimal gas exchange and preserving the integrity of fermenting vegetables by maintaining consistent pressure and minimizing mold growth.

Plastic follower vs Beeswax-sealed follower for fermenting. Infographic

cookingdiff.com

cookingdiff.com