Stoneware crocks provide a traditional, natural environment for fermenting pet foods, allowing beneficial microbes to thrive with consistent temperature retention and anaerobic conditions. Vacuum fermenters enhance fermentation by removing oxygen, reducing contamination risk, and speeding up the process with precise temperature control, resulting in a more predictable outcome. Choosing between the two depends on whether you prioritize artisanal quality and simplicity or enhanced control and efficiency in pet food fermentation.

Table of Comparison

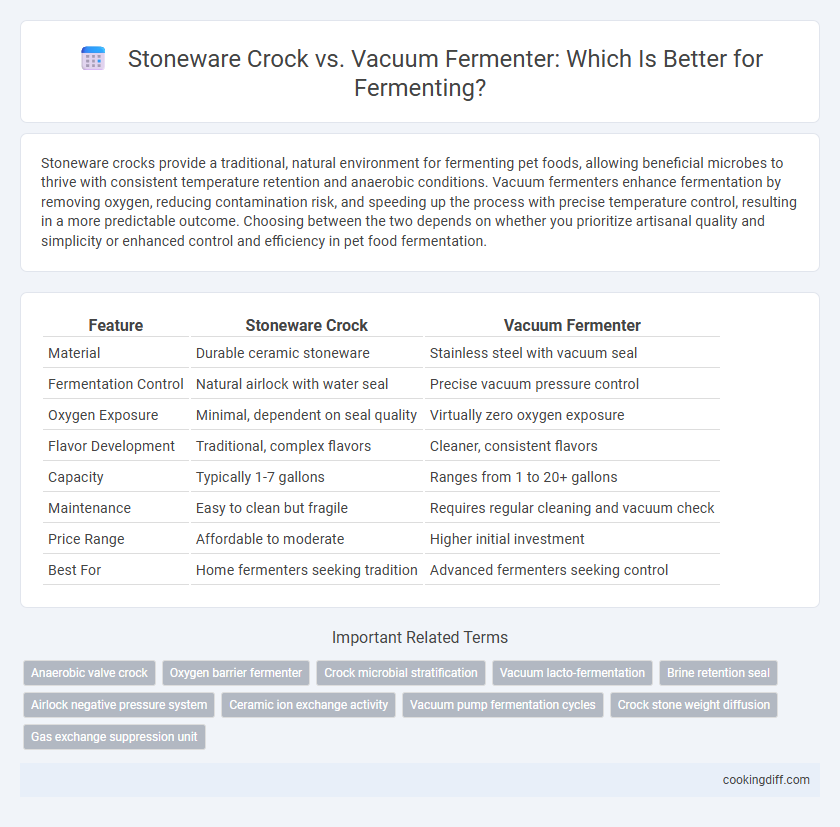

| Feature | Stoneware Crock | Vacuum Fermenter |

|---|---|---|

| Material | Durable ceramic stoneware | Stainless steel with vacuum seal |

| Fermentation Control | Natural airlock with water seal | Precise vacuum pressure control |

| Oxygen Exposure | Minimal, dependent on seal quality | Virtually zero oxygen exposure |

| Flavor Development | Traditional, complex flavors | Cleaner, consistent flavors |

| Capacity | Typically 1-7 gallons | Ranges from 1 to 20+ gallons |

| Maintenance | Easy to clean but fragile | Requires regular cleaning and vacuum check |

| Price Range | Affordable to moderate | Higher initial investment |

| Best For | Home fermenters seeking tradition | Advanced fermenters seeking control |

Introduction to Fermentation Vessels

Stoneware crocks are traditional fermentation vessels made from non-porous ceramic material, offering excellent temperature stability and natural weight to keep fermenting foods submerged. These crocks are ideal for slow fermentation processes like sauerkraut and kimchi, preserving flavors and preventing spoilage.

Vacuum fermenters use airtight seals and vacuum pressure to create an oxygen-free environment, accelerating fermentation and reducing the risk of mold. They provide precise control over fermentation conditions, making them suitable for consistent, rapid results in a wide range of fermented products.

Overview of Stoneware Crocks

Stoneware crocks are traditional fermentation vessels made from dense, non-porous clay that helps maintain a stable environment for fermenting vegetables. Their natural insulation properties regulate temperature, promoting consistent fermentation and preventing spoilage.

These crocks often feature water-sealed rims to create an anaerobic environment crucial for lactic acid bacteria development. The durable material resists acidic conditions, ensuring longevity and safe food contact throughout the fermentation process.

Overview of Vacuum Fermenters

Vacuum fermenters create an oxygen-free environment that accelerates the fermentation process by reducing oxidation risks. Their controlled pressure system enhances the consistency and safety of fermented products compared to traditional stoneware crocks.

- Oxygen removal - Vacuum fermenters actively extract air to minimize exposure to oxygen, preserving microbial activity.

- Pressure control - These devices maintain optimal pressure levels, preventing bloating and spoilage of fermenting foods.

- Enhanced hygiene - Vacuum systems reduce contamination risks by limiting external airborne bacteria and mold.

Material and Build Comparison

Stoneware crocks are made from natural clay fired at high temperatures, offering durability and non-reactive properties ideal for traditional fermentation. Vacuum fermenters utilize stainless steel combined with airtight seals to precisely control oxygen exposure and fermentation speed.

- Material Composition - Stoneware crocks consist of porous ceramic that helps regulate moisture and gas exchange naturally.

- Build and Design - Vacuum fermenters have engineered lids and valves for controlled vacuum pressure, maintaining anaerobic conditions.

- Durability and Maintenance - Stainless steel vacuum fermenters resist corrosion and are easier to sanitize compared to fragile and heavier stoneware crocks.

Oxygen Control and Airflow

| Stoneware Crock | Vacuum Fermenter |

|---|---|

| Stoneware crocks naturally limit oxygen exposure by using heavy lids and water seals, creating an anaerobic environment ideal for fermentation. The weight of the lid presses down on the ferment, minimizing airflow and preventing mold growth. However, minimal gas exchange may lead to the buildup of carbon dioxide within the crock. | Vacuum fermenters actively control oxygen by removing air from the fermentation chamber, ensuring a near-complete anaerobic environment. This system allows precise airflow regulation, preventing oxygen infiltration and reducing oxidation risk. Continuous vacuum ensures CO2 is efficiently expelled while maintaining ideal anaerobic conditions for fermentation. |

Impact on Flavor Profiles

Stoneware crocks allow natural fermentation with minimal oxygen exposure, enhancing complex, earthy flavor profiles. Vacuum fermenters create a low-oxygen environment that slows fermentation, resulting in cleaner and more consistent tastes.

- Stoneware crock promotes wild microbial activity - This encourages unique, robust flavors from diverse bacteria and yeasts.

- Vacuum fermenter maintains constant pressure - This control reduces oxidation, preserving freshness and acidity.

- Material interaction influences taste - Stoneware's porous surface can subtly affect the flavor development.

Choosing between stoneware crock and vacuum fermenter depends on desired complexity and flavor consistency in fermentation.

Ease of Use and Maintenance

Which is easier to use and maintain: a stoneware crock or a vacuum fermenter? Stoneware crocks require manual weight adjustments and periodic cleaning, making maintenance straightforward but somewhat hands-on. Vacuum fermenters feature automated air removal systems that simplify the process, reducing upkeep time while ensuring consistent anaerobic conditions.

Durability and Longevity

Stoneware crocks are renowned for their exceptional durability, offering resistance to chips, cracks, and temperature fluctuations during fermentation. Their robust ceramic composition ensures longevity, often lasting for decades with proper care.

Vacuum fermenters, while innovative and efficient in maintaining anaerobic conditions, typically use materials like plastic or glass that may be more prone to wear over time. The seal integrity in vacuum fermenters requires regular maintenance to prevent leaks, which can affect durability. Stoneware crocks provide a more time-tested, long-lasting solution for fermenting diverse foods.

Cost and Accessibility

Stoneware crocks generally offer a lower upfront cost compared to vacuum fermenters, making them more accessible for home fermenters on a budget. They are widely available at kitchen supply stores and online retailers, ensuring easy purchasing options for beginners. Vacuum fermenters, while more expensive, provide advanced features like air-tight seals but may require a higher investment and limited availability.

Related Important Terms

Anaerobic valve crock

Stoneware crocks with anaerobic valves provide a traditional, oxygen-free environment essential for natural wild fermentation, ensuring consistent flavor development and preventing mold. Vacuum fermenters, while offering precise control over oxygen levels, lack the artisanal qualities and microbial diversity fostered by stoneware anaerobic valve crocks.

Oxygen barrier fermenter

Stoneware crocks provide a natural oxygen barrier due to their dense, non-porous ceramic material, which helps create an anaerobic environment ideal for fermenting vegetables. Vacuum fermenters utilize mechanical suction to actively remove oxygen, offering more precise control over anaerobic conditions and reducing the risk of spoilage or mold growth during fermentation.

Crock microbial stratification

Stoneware crocks promote natural microbial stratification due to their porous surfaces, enabling diverse bacterial colonies to develop and enhance fermentation complexity. Vacuum fermenters create an anaerobic environment that limits oxygen exposure but can reduce microbial diversity, impacting flavor profiles compared to traditional crock fermentation.

Vacuum lacto-fermentation

Vacuum fermenters create an oxygen-free environment that enhances lacto-fermentation by preventing mold growth and preserving beneficial bacteria, resulting in faster and more consistent fermentation compared to traditional stoneware crocks. This method maintains optimal pressure and airtight conditions, promoting higher lactic acid production and improved flavor profiles in fermented vegetables.

Brine retention seal

Stoneware crocks offer a natural, porous material that allows for slight air exchange but rely on water-sealed rims to create an effective brine retention seal, preventing oxygen exposure and spoilage during fermentation. Vacuum fermenters utilize airtight, vacuum-sealed lids that enhance brine retention by actively removing air, significantly reducing oxidation risk and improving fermentation consistency.

Airlock negative pressure system

Stoneware crocks rely on traditional water-sealed airlocks creating a natural anaerobic environment through negative pressure, which effectively prevents oxygen and contaminants from entering during fermentation. In contrast, vacuum fermenters utilize advanced negative pressure systems that actively remove air, offering precise control over fermentation conditions and reducing spoilage risks.

Ceramic ion exchange activity

Stoneware crocks exhibit ceramic ion exchange activity that supports natural fermentation by maintaining stable pH levels and promoting beneficial microbial growth. Vacuum fermenters, while controlling oxygen exposure, lack the ion exchange benefits of ceramic materials, potentially affecting fermentation dynamics and flavor complexity.

Vacuum pump fermentation cycles

Vacuum fermenters utilize vacuum pump fermentation cycles to create an oxygen-free environment that accelerates microbial activity and enhances flavor development in fermented foods. Unlike stoneware crocks, which rely on natural anaerobic conditions, vacuum fermenters offer precise control over fermentation speed and consistency, reducing spoilage risk and improving overall product quality.

Crock stone weight diffusion

Stoneware crocks provide superior weight diffusion during fermentation due to their thick, heavy ceramic walls that maintain consistent pressure on fermenting vegetables, promoting even anaerobic conditions. Vacuum fermenters, while efficient in air removal, lack the natural weight distribution of stoneware, which can impact the texture and flavor development in long-term fermentation processes.

Stoneware crock vs vacuum fermenter for fermenting. Infographic

cookingdiff.com

cookingdiff.com