Open-top vessels allow for natural airflow and easier inspection during fermentation, promoting the growth of beneficial aerobic microorganisms, while vacuum-sealed fermenters create an anaerobic environment that can accelerate fermentation and enhance flavor development by preventing oxidation. The choice between these methods depends on the type of pet product and desired fermentation outcome; open-top vessels are ideal for traditional, slow fermentations, whereas vacuum-sealed fermenters suit faster, controlled processes. Proper temperature and hygiene control remain critical regardless of the vessel type to ensure consistent, safe fermentation results.

Table of Comparison

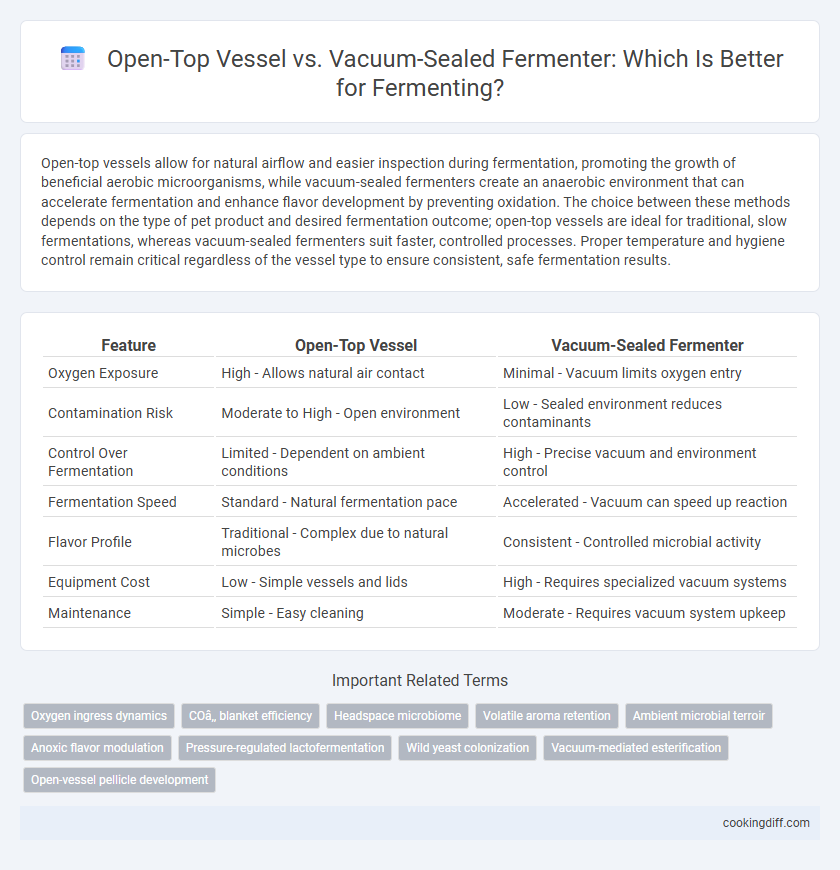

| Feature | Open-Top Vessel | Vacuum-Sealed Fermenter |

|---|---|---|

| Oxygen Exposure | High - Allows natural air contact | Minimal - Vacuum limits oxygen entry |

| Contamination Risk | Moderate to High - Open environment | Low - Sealed environment reduces contaminants |

| Control Over Fermentation | Limited - Dependent on ambient conditions | High - Precise vacuum and environment control |

| Fermentation Speed | Standard - Natural fermentation pace | Accelerated - Vacuum can speed up reaction |

| Flavor Profile | Traditional - Complex due to natural microbes | Consistent - Controlled microbial activity |

| Equipment Cost | Low - Simple vessels and lids | High - Requires specialized vacuum systems |

| Maintenance | Simple - Easy cleaning | Moderate - Requires vacuum system upkeep |

Introduction to Fermentation Vessels

Open-top vessels allow natural airflow and spontaneous fermentation, enhancing microbial diversity during the fermentation process. Vacuum-sealed fermenters provide an anaerobic environment, preventing oxygen exposure and reducing contamination risks. Both vessels influence flavor development and fermentation control, catering to specific fermentation goals.

Open-Top Fermenters: Overview and Features

Open-top fermenters provide a traditional fermentation environment where yeast is exposed to air, promoting natural fermentation dynamics. These vessels are favored in artisanal brewing and winemaking for their ease of access and simplicity in monitoring fermentation progress.

- Design simplicity - Open-top fermenters feature a straightforward, wide-mouth design allowing easy sampling and cleaning.

- Oxygen exposure - The open environment facilitates oxygen contact, which can influence yeast activity and flavor profiles.

- Temperature control - These fermenters often require external methods for temperature regulation, such as glycol jackets or ambient cooling.

Vacuum-Sealed Fermenters: Overview and Features

What are the benefits of using a vacuum-sealed fermenter for fermenting? Vacuum-sealed fermenters create an anaerobic environment that minimizes oxidation and contamination risks, ensuring consistent flavor development. These fermenters often include built-in airlocks and pressure gauges to precisely control fermentation conditions and improve overall product quality.

Oxygen Exposure: Impacts on Fermentation

Open-top vessels expose fermenting substrates to oxygen, promoting aerobic microbial activity that can alter flavor profiles. Vacuum-sealed fermenters limit oxygen exposure, favoring anaerobic fermentation and preserving desired taste and texture.

- Oxygen Exposure in Open-Top Vessels - Encourages growth of aerobic bacteria and yeast, potentially leading to spoilage or off-flavors.

- Vacuum-Sealed Fermenter Environment - Maintains low oxygen levels to support lactic acid bacteria activity, enhancing fermentation consistency.

- Impact on Fermentation Rate - Oxygen presence can accelerate early fermentation but may inhibit complete anaerobic processes necessary for some fermentations.

Flavor Development: Open-Top vs Vacuum-Sealed

Open-top vessels allow for natural oxygen exposure during fermentation, which promotes complex flavor profiles and the development of desirable esters and phenols. This method is ideal for sour beers and other products where oxidative reactions enhance aromatic characteristics.

Vacuum-sealed fermenters limit oxygen contact, preserving fresh, clean flavors by preventing oxidation and microbial contamination. This controlled environment helps maintain subtle, delicate notes preferred in lagers and other light-style beers.

Microbial Activity and Fermentation Outcomes

Open-top vessels promote diverse microbial activity by allowing natural exposure to environmental microorganisms, enhancing flavor complexity in fermentation. Oxygen availability in these vessels supports aerobic microbes, which can influence acidity and texture in the final product.

Vacuum-sealed fermenters create anaerobic conditions that limit exposure to oxygen, favoring the growth of specific anaerobic bacteria and yeasts for controlled fermentation outcomes. This method reduces contamination risk and produces consistent, predictable flavors and microbial profiles, crucial for industrial-scale fermenting.

Managing Contamination Risks

Open-top vessels expose fermenting products to higher contamination risks due to direct contact with air and environmental microbes. Vacuum-sealed fermenters minimize these risks by creating an airtight environment that inhibits unwanted bacterial and mold growth.

The controlled atmosphere inside vacuum-sealed fermenters significantly reduces oxidation and contamination, preserving product quality. In contrast, open-top vessels require frequent monitoring and strict sanitation protocols to prevent spoilage. Selecting the right fermenter type is crucial for maintaining microbial integrity and ensuring consistent fermentation outcomes.

Ease of Use and Maintenance

| Open-top Vessel | Offers straightforward access for stirring, sampling, and cleaning, simplifying maintenance and daily use. Requires regular monitoring to prevent contamination due to exposure to air. Ideal for small-scale or traditional fermentation processes where ease of inspection is critical. |

| Vacuum-sealed Fermenter | Maintains anaerobic conditions automatically, reducing contamination risk and minimizing manual intervention. Cleaning involves careful handling of seals and vacuum components, potentially increasing maintenance complexity. Suits industrial or precise fermentations demanding controlled environments and reduced oxygen exposure. |

Choosing the Right Vessel for Your Fermentation Goals

Open-top vessels allow for greater oxygen exposure ideal for aerobic fermentation processes such as sourdough or kombucha, promoting microbial growth that enhances flavor complexity. Vacuum-sealed fermenters create an anaerobic environment crucial for fermenting products like kimchi or sauerkraut, reducing oxidation and preserving delicate aromas. Selecting the right vessel depends on the desired fermentation outcome, oxygen sensitivity of the ingredients, and control over fermentation conditions.

Related Important Terms

Oxygen ingress dynamics

Open-top vessels allow continuous oxygen ingress, promoting aerobic microbial activity essential in initial fermentation stages, while vacuum-sealed fermenters minimize oxygen exposure, fostering anaerobic conditions that reduce oxidation risk and enhance flavor stability. Controlling oxygen ingress dynamics is critical for optimizing fermentation profiles, where open vessels favor yeast metabolism and vacuum sealing restricts aerobic spoilage organisms.

CO₂ blanket efficiency

Open-top vessels allow CO2 to escape freely, resulting in less effective CO2 blanket protection during fermentation, which increases oxidation risk. Vacuum-sealed fermenters maintain a stable CO2 blanket by preventing gas exchange with the environment, enhancing anaerobic conditions and preserving product quality.

Headspace microbiome

Open-top vessels allow natural exposure of the headspace microbiome, promoting microbial diversity and spontaneous fermentation processes essential for traditional flavor profiles. Vacuum-sealed fermenters minimize oxygen exposure and limit the headspace microbiome, resulting in controlled fermentation with reduced contamination risk and consistent product quality.

Volatile aroma retention

Open-top vessels allow for greater exposure to air, which can lead to the escape of volatile aroma compounds during fermentation, reducing flavor intensity. Vacuum-sealed fermenters create an anaerobic environment that effectively retains volatile aromas, enhancing the overall aromatic profile of the fermented product.

Ambient microbial terroir

Open-top vessels capture and enhance ambient microbial terroir by allowing natural environmental microorganisms to interact directly with the fermenting product, promoting unique and region-specific flavor profiles. Vacuum-sealed fermenters limit this microbial diversity by creating an isolated environment, resulting in more controlled but less terroir-driven fermentation outcomes.

Anoxic flavor modulation

Open-top vessels expose fermenting substrates to atmospheric oxygen, promoting aerobic microbial activity that influences complex flavor development, while vacuum-sealed fermenters create an anoxic environment, enhancing anaerobic fermentation pathways that result in unique, less oxidized flavor profiles. This oxygen limitation in vacuum-sealed systems modulates metabolic byproducts, such as organic acids and esters, crucial for controlled flavor modulation in products like sauerkraut and kimchi.

Pressure-regulated lactofermentation

Vacuum-sealed fermenters maintain consistent low oxygen and pressure-controlled environments ideal for pressure-regulated lactofermentation, enhancing lactic acid bacteria activity and reducing spoilage risk. Open-top vessels expose fermenting substrates to ambient oxygen, resulting in variable pressure conditions that can impede lactic acid bacteria growth and increase the likelihood of unwanted microbial contamination.

Wild yeast colonization

Open-top vessels allow natural exposure to ambient wild yeast, promoting diverse microbial colonization essential for complex fermentation profiles, while vacuum-sealed fermenters restrict oxygen and external yeast, limiting spontaneous wild yeast activity. Wild yeast colonization intensity varies significantly between these methods, influencing flavor complexity and fermentation dynamics.

Vacuum-mediated esterification

Vacuum-sealed fermenters enhance vacuum-mediated esterification by reducing oxygen exposure and promoting controlled pressure, resulting in more efficient ester formation and refined aromatic profiles. Open-top vessels, while traditional, lack this controlled environment, leading to less predictable esterification rates and potential oxidation.

Open-top vessel vs vacuum-sealed fermenter for fermenting. Infographic

cookingdiff.com

cookingdiff.com