Glass jars offer a simple, affordable option for fermenting pets, allowing easy monitoring of the fermentation process through transparency. Anaerobic fermentation vessels provide a controlled oxygen-free environment, reducing the risk of contamination and improving the overall quality of fermentation by maintaining consistent pressure and sealing. Choosing between the two depends on the desired level of control, convenience, and fermentation scale.

Table of Comparison

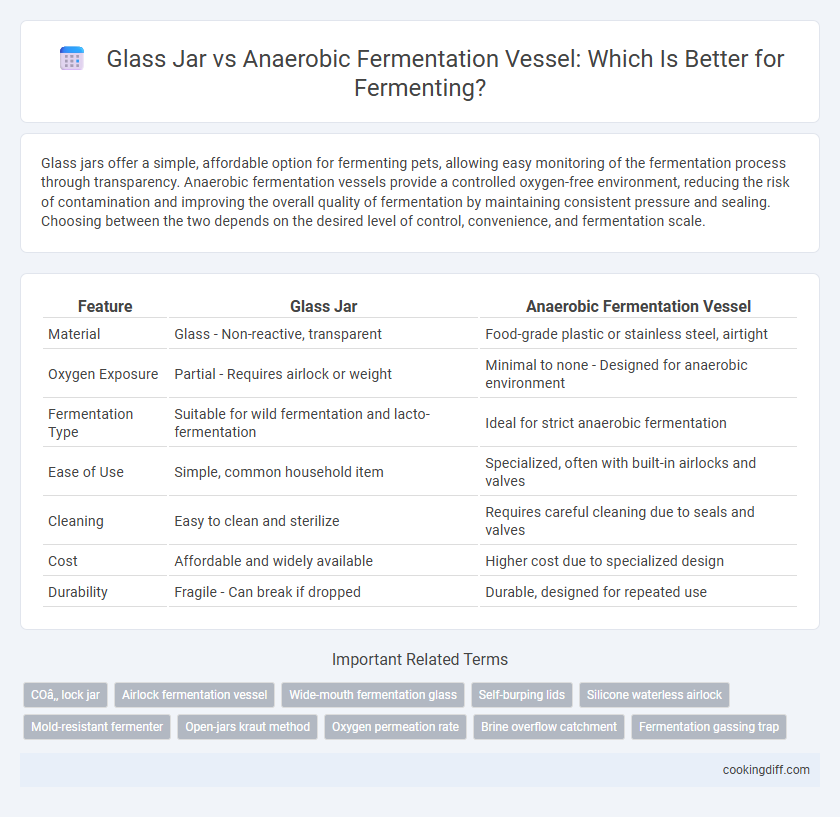

| Feature | Glass Jar | Anaerobic Fermentation Vessel |

|---|---|---|

| Material | Glass - Non-reactive, transparent | Food-grade plastic or stainless steel, airtight |

| Oxygen Exposure | Partial - Requires airlock or weight | Minimal to none - Designed for anaerobic environment |

| Fermentation Type | Suitable for wild fermentation and lacto-fermentation | Ideal for strict anaerobic fermentation |

| Ease of Use | Simple, common household item | Specialized, often with built-in airlocks and valves |

| Cleaning | Easy to clean and sterilize | Requires careful cleaning due to seals and valves |

| Cost | Affordable and widely available | Higher cost due to specialized design |

| Durability | Fragile - Can break if dropped | Durable, designed for repeated use |

Overview: Glass Jar vs Anaerobic Fermentation Vessel

Glass jars are commonly used for small-batch fermenting due to their accessibility and ease of cleaning, but they require an airlock lid or a breathable cover to manage gas exchange and prevent contamination. Anaerobic fermentation vessels provide a controlled environment by eliminating oxygen exposure with built-in airlocks, optimizing conditions for beneficial bacteria and yeast growth. Choosing the right vessel depends on the scale of fermentation, desired flavor profiles, and need for minimizing spoilage risks.

Fermentation Environment: Oxygen Exposure Differences

How does oxygen exposure differ between glass jars and anaerobic fermentation vessels during fermentation? Glass jars allow some oxygen to permeate, potentially leading to aerobic microbial activity that can alter flavor and spoil fermentation. Anaerobic fermentation vessels create a sealed environment that prevents oxygen exposure, promoting the growth of beneficial anaerobic bacteria essential for consistent fermentation results.

Flavor Profile: How Vessel Choice Affects Taste

Glass jars allow for a clearer view of the fermentation process and generally produce a cleaner, crisper flavor due to their non-reactive nature. Anaerobic fermentation vessels create an oxygen-free environment, promoting the growth of specific beneficial bacteria that enhance complex, tangy flavor profiles.

The choice between glass jars and anaerobic fermentation vessels significantly influences the taste outcome of fermented foods. Glass jars often yield milder, more straightforward flavors, while anaerobic vessels intensify sourness and depth by limiting oxygen exposure. This controlled environment supports a richer development of lactic acid bacteria, resulting in a more robust and intricate flavor profile.

Safety Considerations: Preventing Mold and Pathogens

| Glass jars | Non-reactive and easy to sterilize, glass jars reduce contamination risks but require careful sealing to prevent oxygen exposure, which can encourage mold growth. |

| Anaerobic fermentation vessels | Designed to exclude oxygen completely, these vessels minimize mold and pathogen development by maintaining strict anaerobic conditions, enhancing safety during fermentation. |

| Safety considerations | Regular monitoring of pH levels and maintaining clean equipment are essential with both containers to inhibit harmful microbial growth during fermentation. |

Ease of Use: Setup and Maintenance Comparison

Glass jars offer simplicity in setup and cleaning, making them ideal for beginners in fermenting due to their straightforward design and availability. Anaerobic fermentation vessels often include airlocks and specialized seals, which can require more careful assembly and regular monitoring to maintain optimal fermentation conditions. While glass jars are easier to maintain, anaerobic vessels provide a controlled environment that can reduce the risk of contamination, demanding slightly more attention during setup and upkeep.

Cost Analysis: Upfront and Long-term Investment

Glass jars require a lower upfront investment, typically ranging from $5 to $15 per jar, making them accessible for small-scale fermenters and beginners. These jars are versatile but may incur costs over time due to breakage and the need for multiple sizes to accommodate different batch volumes.

Anaerobic fermentation vessels involve a higher initial cost, often between $50 and $200, depending on size and features like airlocks and pressure control. However, their durable construction and specialized design can reduce long-term expenses through improved fermentation consistency and decreased spoilage risk.

Capacity and Batch Size Flexibility

Glass jars typically offer limited capacity, making them suitable for small batch fermenting projects. Anaerobic fermentation vessels come in various sizes, providing more flexibility for larger or multiple batch fermentations.

- Glass jar capacity - Generally ranges from 500ml to 2 liters, ideal for small-scale fermenting.

- Anaerobic vessel sizes - Available in capacities up to 20 liters or more, accommodating larger batch sizes.

- Batch size flexibility - Anaerobic vessels allow easy scalability for both home and commercial fermenting needs.

Cleaning and Sanitization Requirements

Glass jars are non-porous and easy to clean, requiring thorough washing with hot soapy water followed by sanitizing to prevent contamination during fermentation. They do not absorb odors or bacteria, ensuring consistent results with proper maintenance.

Anaerobic fermentation vessels often have complex parts like airlocks and seals that require meticulous disassembly and cleaning to avoid mold and bacterial buildup. They demand regular sanitization with specialized solutions to maintain an oxygen-free environment critical for successful anaerobic fermentation.

Suitability for Various Fermented Foods

Glass jars are ideal for fermenting small batches of vegetables like sauerkraut and kimchi, providing a clear view of the fermentation process. Anaerobic fermentation vessels are better suited for long-term fermentation of beverages such as kombucha and sour beer, where oxygen exposure must be minimized.

- Glass jar transparency - Allows easy monitoring of fermentation progress without opening the container.

- Anaerobic vessel seal - Prevents oxygen exposure, reducing risk of spoilage and contamination.

- Batch size accommodation - Glass jars suit smaller, simple ferments while anaerobic vessels handle larger, complex fermentations.

Choosing the appropriate vessel depends on the specific fermented food and desired fermentation conditions.

Related Important Terms

CO₂ lock jar

Glass jars with CO2 lock systems provide an accessible and cost-effective option for fermenting, allowing gases to escape while preventing oxygen exposure, which minimizes mold growth and spoilage. Anaerobic fermentation vessels offer specialized features such as airtight seals and built-in airlocks that create optimal low-oxygen environments, enhancing the consistency and quality of ferment results in complex fermentations like sauerkraut and kimchi.

Airlock fermentation vessel

An airlock fermentation vessel provides an anaerobic environment critical for preventing oxygen exposure that can spoil fermenting foods, unlike a traditional glass jar which may allow air to seep in. This controlled environment maintains optimal microbial activity by releasing carbon dioxide while blocking contaminants, resulting in consistent and safe fermentation.

Wide-mouth fermentation glass

Wide-mouth fermentation glass jars provide optimal oxygen control and easy access for stirring and monitoring during fermenting, enhancing the growth of beneficial microbes. Unlike anaerobic fermentation vessels, which limit oxygen to create an airtight environment, wide-mouth jars allow selective exposure that balances aerobic and anaerobic microbes for improved flavor profiles.

Self-burping lids

Self-burping lids on glass jars simplify anaerobic fermentation by allowing built-up gases to escape without opening, reducing contamination risk and maintaining an optimal environment for beneficial microbes. Unlike traditional anaerobic fermentation vessels, these lids offer a convenient, airtight seal that ensures consistent fermentation progress and preserves flavor integrity.

Silicone waterless airlock

Silicone waterless airlocks provide a superior anaerobic environment by preventing oxygen exposure and contamination during fermentation, unlike traditional glass jars that require manual sealing and risk introducing air. These specialized vessels maintain consistent pressure and minimize spoilage, optimizing the fermentation process for sauerkraut, kimchi, and other fermented foods.

Mold-resistant fermenter

A glass jar provides a clear, non-reactive environment for fermenting but risks mold growth due to oxygen exposure, while an anaerobic fermentation vessel minimizes mold by maintaining an oxygen-free environment essential for optimal fermentation. Mold-resistant fermenters typically utilize airtight seals and airlocks that prevent contaminants and ensure consistent anaerobic conditions, enhancing preservation and flavor development.

Open-jars kraut method

Open-jars kraut fermentation in glass jars allows natural air exchange, fostering beneficial microbial growth but increasing the risk of surface mold. Anaerobic fermentation vessels create an oxygen-free environment, reducing contamination while enhancing lactic acid bacteria activity and resulting in more consistent sauerkraut flavor and texture.

Oxygen permeation rate

Glass jars exhibit a higher oxygen permeation rate compared to anaerobic fermentation vessels, which are specifically designed to minimize oxygen exposure during fermentation. This reduced oxygen permeation in anaerobic vessels helps maintain an anaerobic environment, essential for optimal microbial activity and preventing spoilage during fermenting processes.

Brine overflow catchment

Glass jars commonly lack specialized features for brine overflow catchment, leading to potential messes during active fermentation phases. Anaerobic fermentation vessels often include built-in airlocks or overflow channels designed to securely capture and contain excess brine, maintaining a clean fermentation environment.

Glass jar vs Anaerobic fermentation vessel for fermenting. Infographic

cookingdiff.com

cookingdiff.com