Metal lids create an airtight seal that can trap gases, increasing the risk of spoilage or explosive pressure buildup during fermenting. Water-seal fermentation lids allow carbon dioxide to escape while preventing oxygen and contaminants from entering, promoting safer and more effective fermentation. Choosing a water-seal lid enhances fermentation control and reduces the likelihood of jar explosions or off-flavors.

Table of Comparison

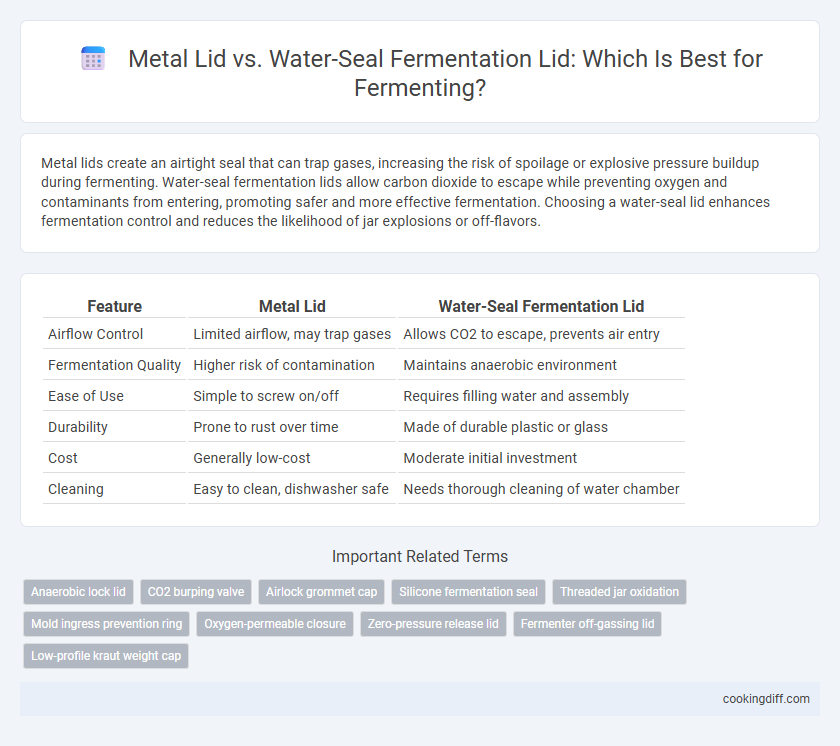

| Feature | Metal Lid | Water-Seal Fermentation Lid |

|---|---|---|

| Airflow Control | Limited airflow, may trap gases | Allows CO2 to escape, prevents air entry |

| Fermentation Quality | Higher risk of contamination | Maintains anaerobic environment |

| Ease of Use | Simple to screw on/off | Requires filling water and assembly |

| Durability | Prone to rust over time | Made of durable plastic or glass |

| Cost | Generally low-cost | Moderate initial investment |

| Cleaning | Easy to clean, dishwasher safe | Needs thorough cleaning of water chamber |

Introduction: Choosing the Right Lid for Fermentation

Choosing the right lid for fermentation is crucial to maintain an anaerobic environment and prevent contamination. Metal lids often require modifications, such as airlocks, to release carbon dioxide safely without compromising the seal. Water-seal fermentation lids provide a reliable, built-in airlock system that allows gases to escape while keeping oxygen and bacteria out, making them ideal for consistent fermentation results.

Overview: Metal Lids vs Water-Seal Fermentation Lids

| Metal Lids | Metal lids provide a tight seal that prevents air entry but can trap gases, sometimes causing pressure build-up during fermentation, requiring occasional releasing of built-up CO2. |

| Water-Seal Fermentation Lids | Water-seal lids allow gases to escape through a water barrier while blocking new air, minimizing contamination risk and reducing the need for manual burping. |

| Comparison | Water-seal fermentation lids offer better airlock functionality for consistent anaerobic fermentation compared to metal lids, which need more aggressive monitoring to prevent pressure issues. |

Airflow and Gas Release: Comparing Lid Designs

Metal lids offer a tight seal that limits airflow and can trap carbon dioxide, increasing pressure inside the fermentation vessel. Water-seal fermentation lids allow gas release through a liquid barrier, preventing contamination while maintaining airflow and preventing oxidation. This design reduces the risk of blowouts and ensures a more controlled fermentation environment.

Oxygen Exposure: Impact on Fermentation Outcomes

Metal lids can create a tight seal but may allow limited oxygen exposure through small imperfections, potentially leading to unwanted aerobic microbial growth during fermentation. Water-seal fermentation lids provide a more effective oxygen barrier by allowing gases to escape while preventing air ingress, thus promoting anaerobic conditions essential for optimal fermentation.

Oxygen exposure influences the balance of microorganisms, often favoring molds and aerobic bacteria over beneficial anaerobes in metal-lid setups. Water-seal lids reduce this risk by maintaining a controlled, low-oxygen environment, resulting in more consistent flavor profiles and improved fermentation quality.

Mold and Contamination Risks: Which Lid Provides Better Protection?

Metal lids create an airtight seal that can sometimes trap gases, increasing the risk of mold growth during fermentation. Water-seal fermentation lids allow gases to escape while preventing airborne contaminants, reducing mold and contamination risks.

- Metal Lid Creates Airtight Environment - Air trapped inside can promote anaerobic conditions where mold may thrive if not monitored closely.

- Water-Seal Lid Allows Gas Escape - CO2 produced during fermentation can safely exit, minimizing pressure buildup and mold formation.

- Water Barrier Blocks Contaminants - The water seal prevents oxygen and airborne microbes from entering, offering superior protection against contamination.

Flavor Development: Does Lid Choice Affect Taste?

Metal lids can create a tighter seal that limits oxygen exposure, often resulting in a cleaner, more consistent flavor in fermented products. However, they may also risk off-flavors if pressure buildup is not released properly during fermentation.

Water-seal fermentation lids allow gases to escape while preventing outside air from entering, promoting rich, complex flavor development due to controlled anaerobic conditions. This method can enhance the depth and tanginess of ferments by maintaining an ideal fermentation environment.

Durability and Reusability: Long-Term Use of Metal and Water-Seal Lids

Which fermentation lid offers superior durability and reusability for long-term use? Metal lids made from stainless steel resist corrosion and maintain a tight seal over multiple fermentation cycles, ensuring consistent performance. Water-seal fermentation lids, while effective in preventing contamination, may require more frequent replacement due to wear and the risk of cracks or leaks.

Ease of Use: Practical Considerations for Home Fermenters

Metal lids offer simplicity and durability, easily securing jars during fermentation with a straightforward screw-on design. Water-seal fermentation lids provide a visual indicator of active fermentation by bubbling air out while preventing oxygen from entering.

Home fermenters appreciate metal lids for their affordability and reusability but must monitor pressure buildup to avoid jar breakage. Water-seal lids simplify fermentation by eliminating the need to manually release gas, making them user-friendly for beginners. Both lid types require careful cleaning to prevent contamination and ensure successful fermentation.

Cleaning and Maintenance of Fermentation Lids

Metal lids for fermenting often require thorough cleaning to prevent rust and accumulation of residues, while water-seal fermentation lids are generally easier to maintain because they avoid direct contact with fermenting liquids. Proper cleaning and maintenance are crucial to ensure the longevity and hygiene of fermentation lids.

- Metal lids prone to rust - Regular drying and avoidance of prolonged moisture exposure help prevent corrosion.

- Water-seal lids minimize contamination - The water barrier reduces exposure to airborne contaminants, simplifying cleaning.

- Frequent inspection recommended - Checking seals and gaskets ensures airtight conditions and prevents mold growth.

Consistent cleaning after each use maximizes the effectiveness and lifespan of both metal and water-seal fermentation lids.

Related Important Terms

Anaerobic lock lid

Anaerobic lock lids, designed with water-seal fermentation systems, create an oxygen-free environment essential for optimal microbial activity during fermenting, preventing mold and harmful bacteria growth. Unlike traditional metal lids, these lids maintain stable pressure release and reduce contamination risk, enhancing fermentation consistency and flavor development.

CO2 burping valve

Metal lids often require manual loosening to release built-up CO2 during fermentation, risking pressure buildup and potential jar breakage. Water-seal fermentation lids feature integrated CO2 burping valves that automatically vent gas while preventing oxygen and contaminants from entering, ensuring a safer and more efficient fermenting process.

Airlock grommet cap

Metal fermentation lids often feature an airlock grommet cap that allows carbon dioxide to escape while preventing oxygen and contaminants from entering, ensuring an anaerobic environment ideal for fermentation. In contrast, water-seal fermentation lids create a liquid barrier that permits gas release and inhibits air exposure, but the airlock grommet cap on metal lids offers a more durable and reusable solution for maintaining consistent fermentation conditions.

Silicone fermentation seal

Silicone fermentation seals provide an airtight barrier that prevents oxygen and contaminants from entering while allowing gas to escape, making them more effective than metal lids for long-term fermentation. Their flexibility and durability ensure a secure fit, minimizing the risk of spoilage compared to water-seal lids, which can be prone to leaks and require more maintenance.

Threaded jar oxidation

Threaded metal lids on fermentation jars often cause oxidation due to airtight sealing that traps gases, increasing pressure and risking lid deformation or bursting. Water-seal fermentation lids allow gases to escape through a liquid barrier, minimizing oxidation and preserving the integrity of the ferment.

Mold ingress prevention ring

Metal lids with a mold ingress prevention ring provide an airtight seal that effectively inhibits mold growth by limiting oxygen exposure during fermentation. Water-seal fermentation lids create a barrier using liquid to allow gas escape while preventing mold and contaminants from entering, maintaining a controlled anaerobic environment.

Oxygen-permeable closure

Metal lids provide a tight seal that limits oxygen exposure, which can hinder the growth of anaerobic fermenting bacteria, whereas water-seal fermentation lids allow controlled oxygen-permeable closure that facilitates gas escape while minimizing oxygen intrusion, supporting optimal fermentation. Oxygen-permeable closures enhance microbial activity by creating an ideal environment for lactic acid bacteria, reducing spoilage risk during fermentation.

Zero-pressure release lid

Zero-pressure release lids for fermenting provide a safer, more efficient alternative to traditional metal lids by allowing gases to escape gradually during fermentation, preventing pressure build-up and reducing the risk of jar breakage. Compared to water-seal fermentation lids, zero-pressure release lids eliminate the need for water refills and minimize contamination risks while maintaining an anaerobic environment ideal for consistent ferment development.

Fermenter off-gassing lid

Metal lids for fermenting often require manual loosening to release gas, risking excessive pressure buildup and potential spoilage, whereas water-seal fermentation lids provide a built-in off-gassing mechanism that allows CO2 to escape while keeping contaminants out. Water-seal lids improve fermentation safety and consistency by maintaining an airtight environment with controlled gas release, reducing oxidation and contamination risks during the off-gassing process.

Metal lid vs water-seal fermentation lid for fermenting. Infographic

cookingdiff.com

cookingdiff.com