Cloth covers allow for natural airflow during pet fermentation, promoting beneficial bacterial growth while preventing contaminants. Vacuum fermentation lids create an airtight seal, reducing oxygen exposure and minimizing the risk of mold formation. Choosing between them depends on the desired fermentation environment and the specific needs of the pet fermentation process.

Table of Comparison

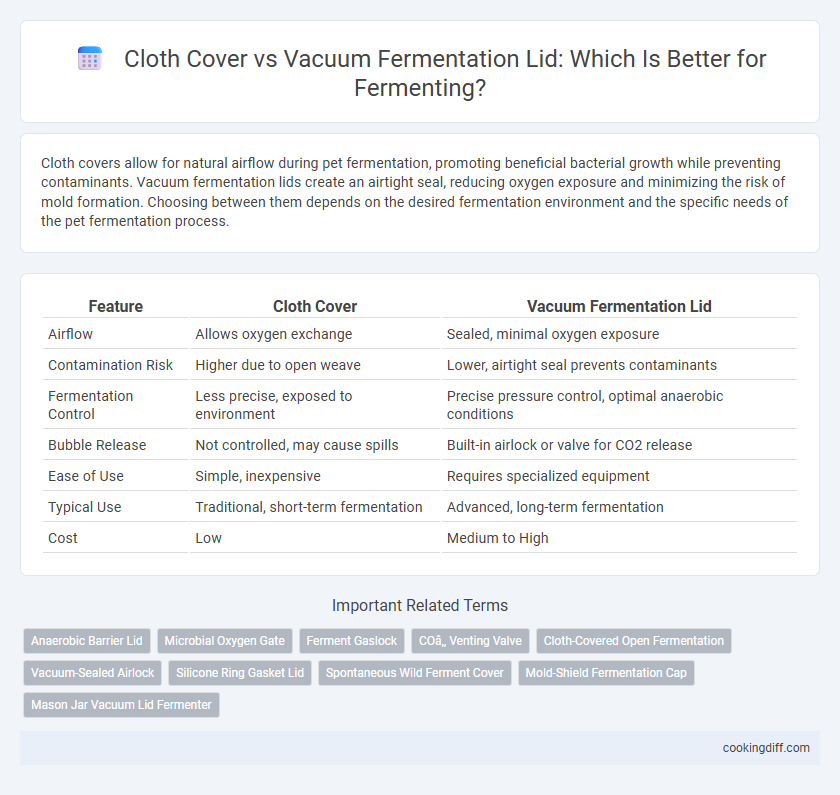

| Feature | Cloth Cover | Vacuum Fermentation Lid |

|---|---|---|

| Airflow | Allows oxygen exchange | Sealed, minimal oxygen exposure |

| Contamination Risk | Higher due to open weave | Lower, airtight seal prevents contaminants |

| Fermentation Control | Less precise, exposed to environment | Precise pressure control, optimal anaerobic conditions |

| Bubble Release | Not controlled, may cause spills | Built-in airlock or valve for CO2 release |

| Ease of Use | Simple, inexpensive | Requires specialized equipment |

| Typical Use | Traditional, short-term fermentation | Advanced, long-term fermentation |

| Cost | Low | Medium to High |

Introduction: Choosing Between Cloth Covers and Vacuum Fermentation Lids

| Cloth covers allow air circulation during fermentation, preventing mold growth while maintaining beneficial aerobic bacteria activity. Vacuum fermentation lids create an anaerobic environment by removing excess air, enhancing preservation and flavor through controlled fermentation. Choosing between the two depends on the type of ferment, desired flavor profile, and level of contamination risk tolerance. |

Airflow Control: How Cloth and Vacuum Lids Differ

How does airflow control differ between cloth covers and vacuum fermentation lids during fermentation? Cloth covers allow natural airflow, promoting beneficial aerobic bacteria while preventing contaminants from entering. Vacuum fermentation lids create a sealed environment, reducing oxygen exposure to favor anaerobic fermentation and preserving flavors more effectively.

Preventing Contamination: Effectiveness of Cloth vs Vacuum-Sealed Lids

Vacuum fermentation lids provide a tighter seal than cloth covers, significantly reducing the risk of airborne contaminants entering the fermenting vessel. Cloth covers allow airflow but may expose ferments to dust, insects, and mold spores, increasing the chance of contamination.

- Vacuum-sealed lids minimize oxygen exposure - creating an anaerobic environment that inhibits harmful microbial growth.

- Cloth covers allow gas exchange - but can let in unwanted particles and microorganisms during fermentation.

- Vacuum lids reduce contamination risk - improving the safety and consistency of fermented products compared to cloth coverings.

Moisture Retention: Cloth Cover Versus Vacuum Lid Performance

Cloth covers allow airflow during fermentation, which can lead to higher moisture evaporation and a drier environment on the ferment's surface. This evaporation helps prevent mold but may cause inconsistent moisture retention compared to sealed methods.

Vacuum fermentation lids create an airtight environment that significantly reduces moisture loss by preventing air exchange. This sealed environment maintains higher humidity levels, promoting uniform fermentation and preserving the brine concentration.

Ease of Use: Practicality of Cloth Covers and Vacuum Lids

Cloth covers offer a simple and affordable method for fermenting, allowing gases to escape while preventing contaminants. Vacuum fermentation lids provide a more controlled environment by sealing jars and reducing oxygen exposure, enhancing the fermentation process.

- Cloth covers are easy to use - They require no special equipment and can be secured with a rubber band.

- Vacuum lids save time - Their airtight seal eliminates the need for daily burping of fermentation jars.

- Maintenance varies - Cloth covers need frequent washing, whereas vacuum lids only require occasional cleaning.

Choosing between cloth covers and vacuum lids depends on the desired convenience and control during fermentation.

Flavor Development: Impact of Each Method on Fermentation

Cloth covers allow airflow and encourage the growth of wild yeasts and bacteria, resulting in complex, tangy flavors in fermented foods. Vacuum fermentation lids create an anaerobic environment that promotes lactic acid bacteria activity, leading to cleaner, more consistent taste profiles.

- Cloth covers promote complexity - Exposure to oxygen supports diverse microbial populations that enhance flavor depth.

- Vacuum lids ensure anaerobic conditions - Reduced oxygen levels favor lactic acid fermentation, producing milder, balanced flavors.

- Flavor consistency - Vacuum lids provide reproducible taste outcomes by limiting unwanted microbial growth compared to cloth covers.

Fermentation Time: Comparing Speed and Consistency

Using a cloth cover during fermentation allows airflow, which can slow down the process and introduce variability in fermentation time due to fluctuating oxygen levels. This method typically requires monitoring to ensure consistent results, especially for delicate fermentations like yogurt or kefir.

Vacuum fermentation lids create an anaerobic environment that accelerates fermentation by maintaining consistent pressure and limiting oxygen exposure, leading to faster and more uniform results. This controlled environment reduces the risk of contamination and shortens overall fermentation time by up to 30% compared to traditional cloth covers.

Reusability and Maintenance: Cloth Cover vs Vacuum Lid Durability

Cloth covers used in fermenting are highly reusable with simple maintenance, often requiring only regular washing and drying to prevent mold buildup. Their durability depends on fabric quality, but they generally wear out faster than vacuum fermentation lids due to exposure to moisture and organic acids.

Vacuum fermentation lids provide greater durability and longevity, constructed from robust materials designed to withstand repeated use and pressure changes. These lids require minimal maintenance, usually needing only occasional cleaning to maintain an airtight seal and prevent contamination. Their reusability surpasses cloth covers, making them a cost-effective option for frequent fermenters seeking consistent fermentation conditions.

Cost Comparison: Initial Investment and Long-Term Savings

Cloth covers for fermenting typically require a low initial investment, often costing just a few dollars, making them an economical choice for beginners. Vacuum fermentation lids involve higher upfront costs, ranging from $20 to $50, but they provide airtight sealing that reduces spoilage and extends shelf life. Over time, vacuum lids offer long-term savings by minimizing product loss and reducing the need for frequent replacements compared to disposable cloth covers.

Related Important Terms

Anaerobic Barrier Lid

Anaerobic Barrier Lids create an airtight seal that prevents oxygen exposure, significantly reducing the risk of mold and spoilage compared to cloth covers in fermentation. This vacuum-based lid maintains an optimal anaerobic environment, enhancing microbial activity and ensuring consistent, high-quality fermentation results.

Microbial Oxygen Gate

Cloth covers allow oxygen flow, promoting aerobic microbial activity ideal for wild fermentations, whereas vacuum fermentation lids create an anaerobic environment by limiting oxygen, optimizing lactic acid bacteria growth and preventing spoilage. The choice between cloth cover and vacuum lid directly influences the microbial oxygen gate, which controls oxygen exposure and shapes the fermentation microbiome's development.

Ferment Gaslock

Ferment gaslocks provide a controlled environment for fermentation by allowing carbon dioxide to escape while preventing oxygen and contaminants from entering, making them more effective than traditional cloth covers. Vacuum fermentation lids enhance this process by maintaining an airtight seal and reducing oxidation risk, thereby improving the quality and consistency of fermented products.

CO₂ Venting Valve

Cloth covers allow natural airflow but lack a CO2 venting valve, increasing the risk of pressure buildup and potential spoilage during fermentation. Vacuum fermentation lids with integrated CO2 venting valves enable controlled gas release, maintaining optimal anaerobic conditions and reducing contamination risks.

Cloth-Covered Open Fermentation

Cloth-covered open fermentation allows airflow while preventing contaminants such as dust and insects from entering, promoting natural microbial activity essential for developing complex flavors. This method supports aerobic fermentation, enhancing the growth of wild yeasts and bacteria, whereas vacuum fermentation lids create an anaerobic environment that may limit flavor complexity.

Vacuum-Sealed Airlock

Vacuum fermentation lids with vacuum-sealed airlocks maintain an anaerobic environment by efficiently expelling excess gas while preventing oxygen ingress, reducing contamination risk and promoting consistent fermentation. Unlike cloth covers that allow oxygen exchange and potential microbial exposure, vacuum-sealed airlocks ensure optimal preservation of flavor and texture during the fermentation process.

Silicone Ring Gasket Lid

A silicone ring gasket lid provides an airtight seal essential for vacuum fermentation, preventing oxygen exposure that can cause spoilage and mold growth, unlike cloth covers which allow airflow and risk contamination. This vacuum lid enhances fermentation control by maintaining optimal anaerobic conditions, resulting in consistent flavor development and extended shelf life of fermented products.

Spontaneous Wild Ferment Cover

A cloth cover for spontaneous wild fermenting allows natural gases to escape while preventing contaminants, supporting the activity of wild yeasts and bacteria crucial for authentic fermentation. Vacuum fermentation lids create an anaerobic environment, slowing unwanted microbial growth but potentially inhibiting the natural flux of beneficial microorganisms during wild fermenting processes.

Mold-Shield Fermentation Cap

The Mold-Shield Fermentation Cap offers an airtight seal that minimizes exposure to oxygen and contaminants, significantly reducing the risk of mold growth during fermentation compared to traditional cloth covers. Its durable silicone design also allows for controlled gas release, ensuring optimal anaerobic conditions essential for high-quality fermentation.

Cloth cover vs Vacuum fermentation lid for fermenting. Infographic

cookingdiff.com

cookingdiff.com