Open-air buckets allow natural airflow and microbial diversity during pet fermenting, promoting complex flavors through traditional methods. Automatic fermenters provide precise temperature and humidity control, ensuring consistent fermentation results and reducing the risk of contamination. Choosing between the two depends on desired flavor complexity versus convenience and reliability in the fermentation process.

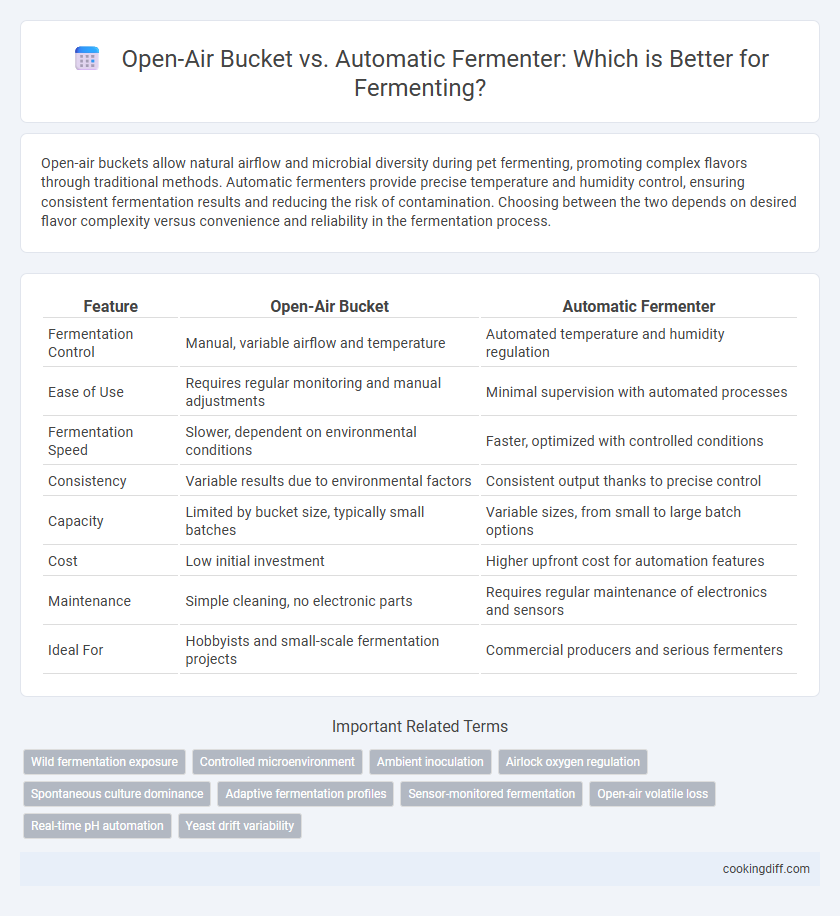

Table of Comparison

| Feature | Open-Air Bucket | Automatic Fermenter |

|---|---|---|

| Fermentation Control | Manual, variable airflow and temperature | Automated temperature and humidity regulation |

| Ease of Use | Requires regular monitoring and manual adjustments | Minimal supervision with automated processes |

| Fermentation Speed | Slower, dependent on environmental conditions | Faster, optimized with controlled conditions |

| Consistency | Variable results due to environmental factors | Consistent output thanks to precise control |

| Capacity | Limited by bucket size, typically small batches | Variable sizes, from small to large batch options |

| Cost | Low initial investment | Higher upfront cost for automation features |

| Maintenance | Simple cleaning, no electronic parts | Requires regular maintenance of electronics and sensors |

| Ideal For | Hobbyists and small-scale fermentation projects | Commercial producers and serious fermenters |

Comparing Open-Air Buckets and Automatic Fermenters

| Fermentation Method | Open-Air Bucket | Automatic Fermenter |

|---|---|---|

| Control | Limited temperature and airflow control, relies on natural conditions | Precise temperature, humidity, and airflow regulation for consistent fermentation |

| Monitoring | Manual observation required to track fermentation progress | Integrated sensors and automated monitoring enable real-time data tracking |

| Cost | Low initial investment, simple setup suitable for small batches | Higher upfront cost with advanced technology optimized for larger or commercial scale |

| Flavor Development | Variable results influenced by ambient microbes and environment | Controlled environment fosters predictable and repeatable flavor profiles |

| Maintenance | Easy to clean but requires frequent manual intervention | Automated cleaning features reduce labor and contamination risk |

Overview: Traditional vs Modern Fermenting Methods

Open-air buckets represent traditional fermenting methods relying on natural environmental conditions and manual monitoring, while automatic fermenters offer precise temperature and humidity control through digital systems. Modern fermenters improve consistency and reduce contamination risks compared to the exposed nature of open-air fermentation.

- Open-air bucket fermentation - Utilizes ambient air and natural yeasts, requiring frequent manual checks to maintain optimal conditions.

- Automatic fermenter - Employs sensors and automated controls to regulate temperature, humidity, and airflow for consistent results.

- Comparison overview - Traditional methods emphasize artisanal qualities and are cost-effective, whereas modern fermenters enhance efficiency and scalability in production.

Key Features of Open-Air Bucket Fermentation

Open-air bucket fermentation allows natural exposure to ambient microbes, enhancing yeast diversity and flavor complexity in the final product. It requires manual temperature control and regular monitoring to prevent contamination and manage fermentation kinetics.

The bucket's wide mouth facilitates oxygen exchange, promoting an aerobic environment ideal for early fermentation stages. Its cost-effective design and ease of cleaning appeal to small-scale and artisanal brewers. However, susceptibility to environmental fluctuations demands careful sanitation and consistent supervision.

Advantages of Automatic Fermenters

Automatic fermenters provide precise control over temperature and fermentation duration, leading to consistent and high-quality results. They minimize the risk of contamination compared to open-air buckets by offering sealed environments.

- Temperature Regulation - Maintains optimal fermentation temperature automatically for better yeast performance.

- Reduced Contamination Risk - Airtight design protects fermenting contents from airborne microbes and contaminants.

- Consistency and Repeatability - Programmable settings enable uniform batches every time without manual monitoring.

Flavor and Texture: Fermentation Outcomes

Open-air buckets expose fermenting ingredients to natural environmental microbes, often enhancing complexity and depth in flavor but can result in inconsistent texture due to fluctuating conditions. Automatic fermenters maintain precise temperature and humidity controls, promoting uniform fermentation and a more predictable, smoother texture.

The open-air method encourages unique, terroir-driven flavor profiles, which many artisans value for traditional fermentation. Automatic fermenters deliver consistent fermentation outcomes, optimizing enzyme activity and microbial balance for a reliable flavor and texture profile every batch.

Ease of Use and Maintenance

Open-air buckets offer simple operation but require frequent cleaning to prevent contamination, while automatic fermenters provide streamlined controls and easier maintenance routines. Automatic fermenters often include self-cleaning features that reduce manual labor and improve hygiene.

- Ease of Use - Open-air buckets need manual monitoring and adjustment throughout the fermentation process.

- Maintenance - Automatic fermenters feature built-in cleaning cycles that minimize hands-on upkeep.

- Hygiene - Automatic fermenters reduce contamination risks due to enclosed systems and automated controls.

Choosing between the two depends on user preference for hands-on involvement versus convenience and consistency.

Cost Analysis: Upfront and Ongoing Expenses

Open-air buckets typically have a lower upfront cost, ranging from $20 to $50, making them accessible for beginners and small-batch fermenters. Automatic fermenters can cost between $200 and $600, with advanced models featuring temperature control and timers that increase initial investment. Ongoing expenses for open-air buckets are minimal, while automatic fermenters may incur higher electricity costs and occasional maintenance fees.

Safety and Contamination Risks

Open-air buckets increase exposure to airborne contaminants and pests, heightening the risk of unsafe fermentation outcomes. Automatic fermenters feature sealed environments with controlled conditions, significantly reducing contamination risks and ensuring consistent safety. Choosing an automatic fermenter enhances product quality by minimizing exposure to harmful microorganisms and safeguarding the fermentation process.

Batch Size and Scalability Options

Open-air buckets are ideal for small-batch fermenting, typically accommodating up to 5 gallons, making them suitable for home use or experimental batches. Their manual operation limits scalability, as increasing batch size requires additional buckets and more hands-on monitoring.

Automatic fermenters support larger batch sizes, from 5 to 60 gallons or more, and offer programmable settings that enhance consistency and scalability for commercial production. These systems streamline fermentation workflows, allowing producers to scale operations efficiently without proportional increases in labor.

Related Important Terms

Wild fermentation exposure

Open-air buckets expose fermenting products to natural wild yeast and bacteria in the environment, enhancing the development of complex, unique flavors through spontaneous fermentation. Automatic fermenters provide controlled conditions that limit wild microbial exposure, resulting in more consistent but less diverse microbial activity during fermentation.

Controlled microenvironment

Open-air buckets allow natural airflow but expose fermenting products to variable temperatures and contaminants, making it challenging to maintain a controlled microenvironment. Automatic fermenters offer precise temperature regulation, humidity control, and reduced oxidation risk, ensuring consistent and optimized fermentation conditions.

Ambient inoculation

Open-air bucket fermenting relies on ambient inoculation, where wild yeast and bacteria naturally present in the environment initiate fermentation, enhancing microbial diversity and complex flavor profiles. Automatic fermenters utilize controlled environments and selected starter cultures, reducing reliance on ambient microbes and providing consistent fermentation conditions with minimized contamination risk.

Airlock oxygen regulation

Open-air buckets expose fermenting liquids to ambient oxygen, increasing the risk of contamination and inconsistent fermentation due to uncontrolled air exposure. Automatic fermenters feature built-in airlock oxygen regulation systems that maintain anaerobic conditions, ensuring consistent fermentation and preventing spoilage by limiting oxygen contact.

Spontaneous culture dominance

Open-air buckets allow for spontaneous culture dominance by exposing fermenting ingredients to ambient wild yeasts and bacteria, creating a unique and complex flavor profile influenced by the local environment. Automatic fermenters control temperature and fermentation parameters but often limit the diversity of spontaneous microorganisms, resulting in more consistent yet less variable microbial populations.

Adaptive fermentation profiles

Open-air buckets offer flexible, manual control over fermentation profiles, allowing precise adjustments to temperature and aeration based on environmental conditions. Automatic fermenters provide adaptive fermentation profiles through integrated sensors and programmable settings, ensuring consistent, repeatable results by dynamically regulating temperature, agitation, and oxygen levels.

Sensor-monitored fermentation

Sensor-monitored fermentation in automatic fermenters enhances precision by continuously tracking temperature, pH, and CO2 levels, ensuring optimal microbial activity and consistent results. Open-air buckets lack this real-time monitoring, increasing the risk of contamination and fermentation inconsistencies due to environmental fluctuations.

Open-air volatile loss

Open-air buckets for fermenting expose the product to ambient conditions, resulting in significant volatile compound loss due to evaporation and oxidation. Automatic fermenters minimize this volatile loss by maintaining controlled environments with sealed lids and regulated temperature, preserving flavor profiles more effectively.

Real-time pH automation

Open-air buckets lack real-time pH automation, requiring manual monitoring and adjustment to maintain optimal fermentation conditions. Automatic fermenters feature integrated sensors that continuously track pH levels, enabling precise control and consistent quality throughout the fermentation process.

Open-air bucket vs automatic fermenter for fermenting. Infographic

cookingdiff.com

cookingdiff.com