Wooden barrels provide a traditional, breathable environment ideal for natural fermentation, allowing subtle oxygen exchange that enhances flavor complexity in fermented pet foods. Anaerobic fermenters create a sealed, oxygen-free environment that accelerates fermentation and reduces the risk of contamination, ensuring consistent and controlled results. Choosing between wooden barrels and anaerobic fermenters depends on whether flavor development or process control is prioritized during pet food fermentation.

Table of Comparison

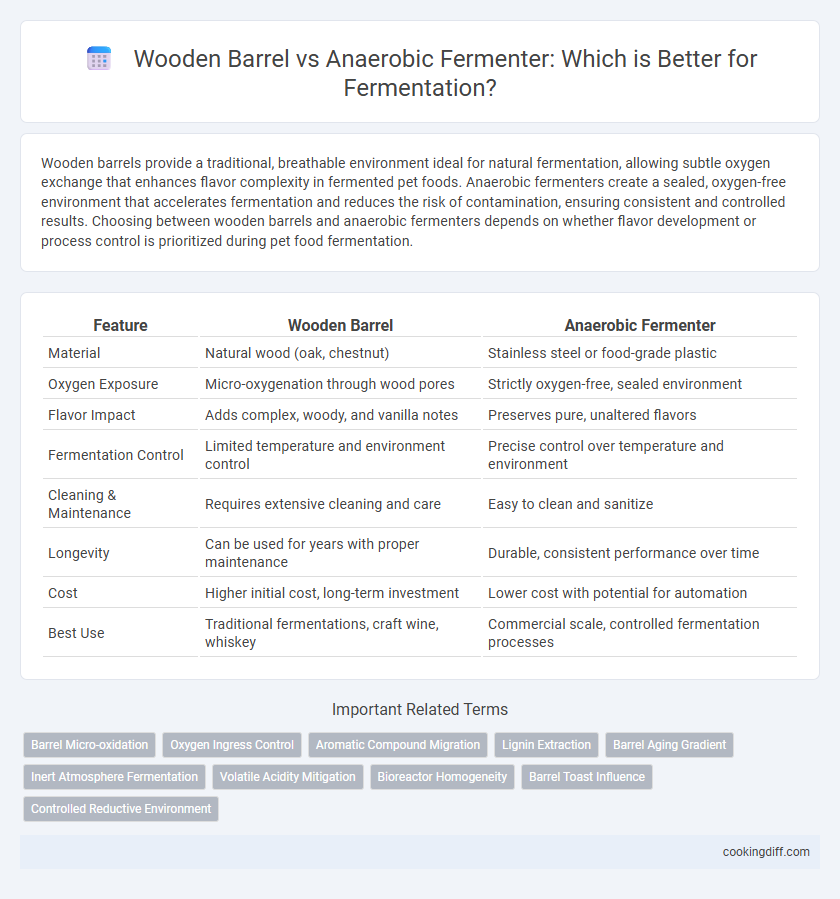

| Feature | Wooden Barrel | Anaerobic Fermenter |

|---|---|---|

| Material | Natural wood (oak, chestnut) | Stainless steel or food-grade plastic |

| Oxygen Exposure | Micro-oxygenation through wood pores | Strictly oxygen-free, sealed environment |

| Flavor Impact | Adds complex, woody, and vanilla notes | Preserves pure, unaltered flavors |

| Fermentation Control | Limited temperature and environment control | Precise control over temperature and environment |

| Cleaning & Maintenance | Requires extensive cleaning and care | Easy to clean and sanitize |

| Longevity | Can be used for years with proper maintenance | Durable, consistent performance over time |

| Cost | Higher initial cost, long-term investment | Lower cost with potential for automation |

| Best Use | Traditional fermentations, craft wine, whiskey | Commercial scale, controlled fermentation processes |

Introduction to Fermentation: Wooden Barrels vs Anaerobic Fermenters

Fermentation in wooden barrels allows for natural oxygen exchange, which can enhance flavor complexity in beverages like wine and whiskey. Anaerobic fermenters provide a controlled environment that limits oxygen exposure, reducing contamination risks and ensuring consistent fermentation outcomes.

- Wooden barrels facilitate micro-oxygenation - This process influences the aging and taste profile by allowing slow oxygen penetration through the wood pores.

- Anaerobic fermenters maintain strict oxygen-free conditions - They prevent oxidation and microbial spoilage by sealing fermentation vessels tightly.

- Wooden barrels contribute to unique flavor compounds - The wood imparts tannins and other elements that enrich the fermented product's aroma and texture.

Historical Overview of Wooden Barrel Fermentation

Wooden barrel fermentation has been practiced for centuries, with origins tracing back to ancient civilizations like the Romans and Celts, who utilized oak barrels for wine and beer production. The porous nature of wood allows micro-oxygenation, enhancing the complexity and depth of fermented beverages.

In contrast, anaerobic fermenters provide a controlled environment that minimizes oxygen exposure, preserving the pure yeast flavors without the influence of wood tannins. Despite modern advancements, wooden barrels remain valued for imparting unique sensory characteristics and tradition in craft fermentation.

Modern Innovations: Anaerobic Fermenters Explained

Modern anaerobic fermenters offer precise control over fermentation conditions such as temperature, pH, and oxygen levels, leading to consistent and efficient microbial activity. Unlike traditional wooden barrels that allow slow oxygen exchange influencing flavor complexity, anaerobic fermenters create completely oxygen-free environments to optimize anaerobic microorganism growth. This innovation results in faster fermentation cycles and improved product purity, making it ideal for industrial-scale fermenting processes.

Key Differences in Fermentation Environments

Wooden barrels allow slow oxygen diffusion, creating micro-oxidation that influences flavor complexity, while anaerobic fermenters provide a strictly oxygen-free environment for controlled fermentation. The material differences result in varied microbial activity and fermentation rates affecting the final product's taste and texture.

- Oxygen Exposure - Wooden barrels permit limited oxygen ingress, enhancing flavor development, whereas anaerobic fermenters maintain an oxygen-free setting to prevent oxidation.

- Microbial Activity - The porous nature of wood supports diverse microbial ecosystems, while stainless steel anaerobic fermenters restrict microorganisms to those intentionally introduced.

- Temperature Control - Anaerobic fermenters often have precise temperature regulation systems, contrasting with wooden barrels that have natural temperature fluctuations impacting fermentation dynamics.

Impact on Flavor and Aroma Profiles

Wooden barrels impart complex, woody flavors and subtle tannins to fermented products, enhancing aroma profiles with notes of vanilla, spice, and oak. Anaerobic fermenters preserve the pure, fruit-forward characteristics of the fermenting ingredients by minimizing oxygen exposure, resulting in cleaner and more consistent flavors.

Fermentation in wooden barrels introduces micro-oxygenation, which promotes the development of nuanced aromatic compounds and smooths harsh elements in the product. The porous nature of wood allows beneficial microorganisms to interact, adding depth and richness to the flavor complexity. Anaerobic fermenters, often made of stainless steel or other inert materials, maintain strict oxygen-free conditions that prioritize freshness and clarity over flavor complexity.

Control and Consistency: Barrel vs Fermenter

Wooden barrels offer natural micro-oxygenation that can enhance flavor complexity but result in less precise control over fermentation conditions. Anaerobic fermenters provide consistent, controlled environments minimizing variables and ensuring replicable results.

- Oxygen Exposure - Barrels allow slow oxygen ingress impacting yeast activity and flavor development.

- Temperature Control - Fermenters enable precise temperature regulation crucial for predictable fermentation.

- Sanitation - Stainless steel fermenters are easier to clean, reducing contamination risks compared to porous wood.

Choosing between a wooden barrel and an anaerobic fermenter depends on the desired balance of tradition and precision in fermentation control.

Maintenance and Longevity: Which Lasts Longer?

Wooden barrels require regular maintenance such as cleaning, hydration, and occasional repairs to prevent leaks and microbial contamination, which can shorten their lifespan. Their porous nature allows oxygen exchange, necessitating careful upkeep to maintain fermentation quality and barrel integrity.

Anaerobic fermenters, typically made from stainless steel or food-grade plastic, offer easier maintenance with simple cleaning protocols and no risk of oxygen exposure. These fermenters generally last longer due to their durable, non-porous materials and resistance to corrosion and microbial growth.

Cost Analysis: Investment and Operational Expenses

Wooden barrels require a higher initial investment due to craftsmanship and material costs, often ranging from $500 to $2,000 per barrel depending on size and wood quality. Anaerobic fermenters have a larger upfront expense, typically between $10,000 and $50,000, driven by stainless steel construction and integrated temperature control systems. Operational costs for wooden barrels include maintenance and replacement every few years, while anaerobic fermenters incur energy and cleaning expenses, but offer greater longevity and consistent fermentation conditions.

Sustainability and Material Considerations

How do wooden barrels compare to anaerobic fermenters in terms of sustainability and material considerations? Wooden barrels are made from natural, renewable resources and often have a lower carbon footprint due to their biodegradability and long lifespan. Anaerobic fermenters, typically constructed from stainless steel or plastic, offer greater durability and easier cleaning but involve higher energy consumption and potential environmental impacts from production and disposal.

Related Important Terms

Barrel Micro-oxidation

Wooden barrels enable natural micro-oxidation during fermentation, enhancing complex flavor development and aging potential through controlled oxygen exposure. In contrast, anaerobic fermenters prevent oxygen contact entirely, preserving fresh, fruit-forward characteristics without the oxidative nuances imparted by barrel aging.

Oxygen Ingress Control

Wooden barrels provide micro-oxygenation due to their porous structure, enabling controlled oxygen ingress that enhances fermentation complexity and flavor development. Anaerobic fermenters maintain a strict oxygen-free environment using airtight seals and inert gas blankets, minimizing oxygen exposure to preserve fresh and consistent fermentation profiles.

Aromatic Compound Migration

Wooden barrels promote aromatic compound migration through micro-oxygenation and interaction with wood tannins, enriching complexity and depth in fermentation products. Anaerobic fermenters maintain a sealed environment, preserving fresh and primary aromas by preventing oxygen exposure and limiting flavor compound evolution.

Lignin Extraction

Wooden barrels enhance lignin extraction during fermentation by allowing micro-oxygenation that breaks down lignin compounds, enriching the flavor profile of fermented products. Anaerobic fermenters, by contrast, limit oxygen exposure, resulting in lower lignin degradation and a different chemical composition in the final product.

Barrel Aging Gradient

Wooden barrels provide a natural barrel aging gradient, allowing for slow oxygen diffusion and complex flavor development through micro-oxidation; anaerobic fermenters, by contrast, maintain a strictly oxygen-free environment, preventing oxidation but lacking the nuanced maturation gradients of barrel aging. The porous nature of wood promotes gradual fermentation changes and tannin integration, while anaerobic fermenters prioritize consistency and control over the oxidative aging process.

Inert Atmosphere Fermentation

Wooden barrels naturally allow micro-oxygenation through their porous structure, impacting flavor complexity during fermentation, while anaerobic fermenters maintain a strict inert atmosphere that prevents oxygen exposure, optimizing preservation of desired volatile compounds. Inert atmosphere fermentation utilizing stainless steel or glass tanks ensures controlled conditions, reducing oxidation risks and microbial contamination for consistent product quality.

Volatile Acidity Mitigation

Wooden barrels naturally allow micro-oxygenation, which can reduce volatile acidity by stabilizing the fermentation environment, while anaerobic fermenters provide a sealed atmosphere that minimizes oxygen exposure but may increase the risk of volatile acid buildup if not properly managed. Monitoring fermentation parameters such as temperature and pH is crucial in both systems to effectively mitigate volatile acidity and ensure product quality.

Bioreactor Homogeneity

Wooden barrels often provide uneven fermentation environments due to natural porosity and variable oxygen permeability, which can lead to inconsistent microbial activity and flavor profiles. Anaerobic fermenters enhance bioreactor homogeneity by maintaining controlled, oxygen-free conditions and uniform temperature and mixing, optimizing microbial growth and metabolite production.

Barrel Toast Influence

Barrel toast level significantly impacts flavor compounds during fermentation, with heavier toasting enhancing smoky, caramelized notes in wooden barrels, while anaerobic fermenters preserve more pure, unaltered fruit characteristics by limiting oxygen exposure. The choice between wooden barrels and stainless steel anaerobic fermenters directly influences the chemical reactions of Maillard compounds and phenolic extraction, shaping the final profile of fermented products such as wine and beer.

Wooden barrel vs Anaerobic fermenter for fermenting. Infographic

cookingdiff.com

cookingdiff.com