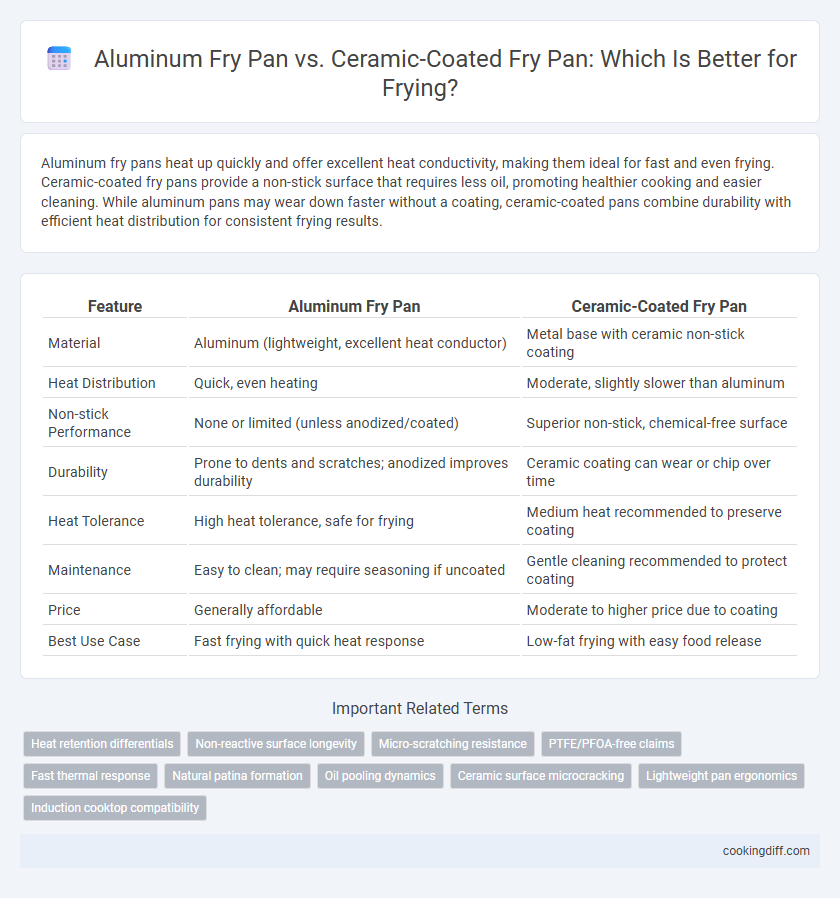

Aluminum fry pans heat up quickly and offer excellent heat conductivity, making them ideal for fast and even frying. Ceramic-coated fry pans provide a non-stick surface that requires less oil, promoting healthier cooking and easier cleaning. While aluminum pans may wear down faster without a coating, ceramic-coated pans combine durability with efficient heat distribution for consistent frying results.

Table of Comparison

| Feature | Aluminum Fry Pan | Ceramic-Coated Fry Pan |

|---|---|---|

| Material | Aluminum (lightweight, excellent heat conductor) | Metal base with ceramic non-stick coating |

| Heat Distribution | Quick, even heating | Moderate, slightly slower than aluminum |

| Non-stick Performance | None or limited (unless anodized/coated) | Superior non-stick, chemical-free surface |

| Durability | Prone to dents and scratches; anodized improves durability | Ceramic coating can wear or chip over time |

| Heat Tolerance | High heat tolerance, safe for frying | Medium heat recommended to preserve coating |

| Maintenance | Easy to clean; may require seasoning if uncoated | Gentle cleaning recommended to protect coating |

| Price | Generally affordable | Moderate to higher price due to coating |

| Best Use Case | Fast frying with quick heat response | Low-fat frying with easy food release |

Overview: Aluminum vs Ceramic-Coated Fry Pans for Frying

Aluminum fry pans offer excellent heat conductivity, ensuring even cooking and quick temperature adjustments, making them ideal for frying. Ceramic-coated fry pans provide a non-stick surface that requires less oil, promoting healthier cooking and easier cleanup. While aluminum pans are lightweight and durable, ceramic coatings can wear over time, affecting their performance and lifespan.

Heat Conductivity: Aluminum vs Ceramic-Coated Fry Pans

Aluminum fry pans offer superior heat conductivity, allowing for even and rapid heating during frying. Ceramic-coated fry pans provide a more moderate heat distribution, which can prevent hot spots but may result in slower cooking times.

- Aluminum Pan Heat Conductivity - Aluminum's thermal conductivity is approximately 235 W/m*K, significantly higher than ceramic coatings, ensuring quick and uniform temperature changes.

- Ceramic-Coated Pan Heat Distribution - Ceramic coatings generally conduct heat at around 1.5 W/m*K, offering gentler and more gradual heat transfer, reducing the risk of burning food.

- Impact on Frying Efficiency - The high heat conductivity of aluminum pans enhances frying efficiency by minimizing cooking time and improving temperature control, whereas ceramic-coated pans prioritize heat retention and non-stick benefits.

Nonstick Performance: Ceramic-Coated vs Traditional Aluminum

Ceramic-coated fry pans provide superior nonstick performance due to their smooth, non-porous surface that resists food sticking even without excessive oil. Traditional aluminum fry pans rely on seasoning or synthetic coatings that can wear off, leading to decreased nonstick effectiveness over time.

Ceramic coatings also offer better heat retention and distribute heat evenly, enhancing frying results by preventing hot spots where food might stick or burn. Aluminum pans heat quickly but may require more maintenance to maintain their nonstick properties, making ceramic-coated options more convenient for consistent frying performance.

Durability and Longevity Comparison

Aluminum fry pans offer excellent heat conductivity but tend to warp and scratch more easily over time, reducing their durability. Their non-stick coating often wears off after extensive use, necessitating replacement within a few years.

Ceramic-coated fry pans provide superior scratch resistance and maintain their non-stick surface longer, contributing to enhanced longevity. However, they require careful handling to avoid chipping, which can compromise their durability over time.

Health and Safety: Frying with Aluminum vs Ceramic-Coated Pans

Is frying with aluminum pans safe compared to ceramic-coated pans? Aluminum fry pans may leach trace amounts of aluminum into food, especially when cooking acidic ingredients, raising health concerns over long-term exposure. Ceramic-coated pans provide a non-toxic, non-reactive surface that reduces the risk of chemical contamination during frying, enhancing kitchen safety.

Ease of Cleaning: Which Pan is More User-Friendly?

Aluminum fry pans typically offer a smooth surface that resists food sticking, making them easier to clean with just a quick wipe or rinse. Ceramic-coated fry pans provide a non-stick experience but may require more careful cleaning to prevent damaging the coating. Users often find aluminum pans more user-friendly for routine cleaning due to their durability and resistance to scrubbing.

Cooking Results: Texture and Browning in Frying

| Aluminum Fry Pan | Offers rapid, even heat distribution, ensuring consistent browning and a crispy texture on fried foods. Its excellent thermal conductivity minimizes hot spots, enhancing Maillard reaction outcomes for richer flavors. |

| Ceramic-Coated Fry Pan | Provides a non-stick surface that requires less oil, promoting healthier frying with tender textures. However, ceramic coatings can heat unevenly, sometimes resulting in less pronounced browning compared to aluminum pans. |

Maintenance Requirements: Aluminum vs Ceramic-Coated Fry Pans

Aluminum fry pans require regular seasoning to maintain their non-stick properties and prevent oxidation, while ceramic-coated fry pans demand gentle cleaning with non-abrasive sponges to preserve their coating. Both types avoid metal utensils to reduce surface damage.

Maintenance for aluminum pans includes avoiding acidic foods that can discolor or corrode the surface, and hand washing is recommended to prolong lifespan. Ceramic-coated pans deteriorate if exposed to high heat or harsh detergents, which can cause the coating to crack or peel. Proper storage and care significantly extend the durability and performance of both aluminum and ceramic-coated fry pans.

Price and Value: Which Fry Pan is Worth the Investment?

Aluminum fry pans generally offer a lower upfront cost and excellent heat conductivity, making them a budget-friendly option for everyday frying. Ceramic-coated fry pans come at a higher price but provide superior non-stick properties and durability, potentially saving money over time by reducing the need for replacement.

- Aluminum pans are affordable - Typically priced lower due to simple manufacturing processes and widespread availability.

- Ceramic coating adds value - Enhances non-stick performance and requires less oil, promoting healthier cooking.

- Longevity differs - Ceramic-coated pans often last longer than aluminum ones if properly maintained, offsetting initial costs.

Choosing the right fry pan depends on balancing initial investment with long-term cooking needs and maintenance preferences.

Related Important Terms

Heat retention differentials

Aluminum fry pans heat up quickly but have lower heat retention, causing temperature fluctuations during frying, while ceramic-coated fry pans maintain consistent heat longer due to better heat retention properties. This difference affects cooking performance, with ceramic coatings providing more even and stable frying temperatures.

Non-reactive surface longevity

Aluminum fry pans often have a reactive surface that can degrade with acidic foods, reducing longevity, while ceramic-coated fry pans provide a durable, non-reactive surface that maintains performance over extended use. The ceramic coating prevents metal leaching and corrosion, making it ideal for long-term frying with minimal surface deterioration.

Micro-scratching resistance

Aluminum fry pans offer high thermal conductivity but are prone to micro-scratching, which can compromise their surface over time. Ceramic-coated fry pans provide superior micro-scratching resistance due to their hard, non-porous surface, maintaining durability and non-stick performance during frequent frying.

PTFE/PFOA-free claims

Aluminum fry pans offer excellent heat conductivity but often require a non-stick coating that may contain PTFE or PFOA, whereas ceramic-coated fry pans provide a PTFE/PFOA-free alternative with durable, non-toxic surfaces ideal for healthier frying. Ceramic coatings resist high temperatures without releasing harmful chemicals, making them a safer choice compared to traditional PTFE-based non-stick aluminum pans.

Fast thermal response

Aluminum fry pans offer superior fast thermal response due to their high thermal conductivity of approximately 237 W/mK, enabling quick and even heat distribution for precise frying control. In contrast, ceramic-coated fry pans have lower thermal conductivity, resulting in slower heat-up times and less responsive temperature adjustment during cooking.

Natural patina formation

Aluminum fry pans develop a natural patina over time that enhances non-stick properties and improves heat distribution, while ceramic-coated fry pans rely on their synthetic layer which may wear off and reduce durability. This patina formation in aluminum pans creates a resilient surface ideal for frying compared to the potential chipping and reduced performance of ceramic coatings.

Oil pooling dynamics

Aluminum fry pans heat rapidly and distribute temperature evenly, minimizing oil pooling and enabling consistent frying with less oil waste. Ceramic-coated fry pans tend to have a slightly rougher surface texture that can cause more oil pooling and uneven heat distribution, potentially leading to inconsistent frying results and increased oil usage.

Ceramic surface microcracking

Ceramic-coated fry pans are prone to surface microcracking due to thermal stress and frequent temperature changes, which can compromise their non-stick properties and durability during frying. Aluminum fry pans, while excellent for heat conduction, do not face microcracking issues but may require seasoning or additional coatings to prevent food sticking.

Lightweight pan ergonomics

Aluminum fry pans offer superior lightweight ergonomics, enhancing maneuverability and reducing wrist strain during frying, while ceramic-coated fry pans, although slightly heavier, provide a comfortable grip and even heat distribution that supports precise cooking control. The low mass of aluminum ensures faster response to temperature changes, making it ideal for quick frying techniques.

Aluminum fry pan vs ceramic-coated fry pan for frying. Infographic

cookingdiff.com

cookingdiff.com