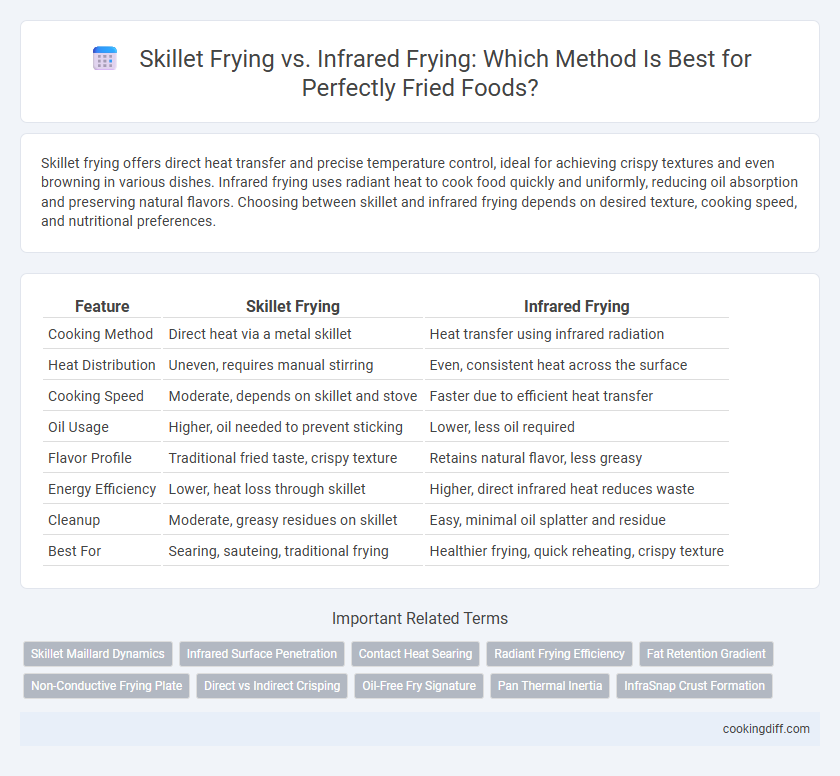

Skillet frying offers direct heat transfer and precise temperature control, ideal for achieving crispy textures and even browning in various dishes. Infrared frying uses radiant heat to cook food quickly and uniformly, reducing oil absorption and preserving natural flavors. Choosing between skillet and infrared frying depends on desired texture, cooking speed, and nutritional preferences.

Table of Comparison

| Feature | Skillet Frying | Infrared Frying |

|---|---|---|

| Cooking Method | Direct heat via a metal skillet | Heat transfer using infrared radiation |

| Heat Distribution | Uneven, requires manual stirring | Even, consistent heat across the surface |

| Cooking Speed | Moderate, depends on skillet and stove | Faster due to efficient heat transfer |

| Oil Usage | Higher, oil needed to prevent sticking | Lower, less oil required |

| Flavor Profile | Traditional fried taste, crispy texture | Retains natural flavor, less greasy |

| Energy Efficiency | Lower, heat loss through skillet | Higher, direct infrared heat reduces waste |

| Cleanup | Moderate, greasy residues on skillet | Easy, minimal oil splatter and residue |

| Best For | Searing, sauteing, traditional frying | Healthier frying, quick reheating, crispy texture |

Introduction to Skillet Frying and Infrared Frying

Skillet frying involves cooking food in a hot, flat-bottomed pan using direct heat, allowing for even browning and a crispy texture. This traditional method uses oil or fat to conduct heat and enhance flavor, making it ideal for searing meats and sauteing vegetables.

Infrared frying utilizes infrared radiation to cook food quickly and evenly without submerging it in oil, promoting a healthier cooking process. The technology heats food surfaces directly, resulting in less oil absorption and faster cooking times compared to conventional frying methods.

How Skillet Frying Works

Skillet frying uses direct contact heat from a heated pan to cook food by transferring thermal energy through conduction. This method allows precise control over temperature, making it ideal for searing and browning.

Infrared frying, in contrast, relies on radiant heat to cook food without direct contact, enabling faster and more even heat distribution. Skillet frying provides a tactile cooking experience, essential for adjusting heat and texture in real-time.

How Infrared Frying Works

| Infrared frying utilizes infrared radiation to directly heat the surface of the food, enabling rapid and even cooking without overheating the surrounding air. This method enhances heat transfer efficiency by converting electrical energy into radiant heat waves, which penetrate the food's outer layer to promote crispiness while retaining moisture inside. Compared to skillet frying, infrared frying reduces oil absorption and cooking time, resulting in healthier and more consistent results. |

Heat Distribution: Skillet vs Infrared

How does heat distribution differ between skillet frying and infrared frying? Skillet frying provides direct contact heat with some uneven hotspots due to pan thickness and material. Infrared frying offers rapid, uniform heat distribution by emitting infrared energy that evenly penetrates food surfaces.

Cooking Time Comparison

Skillet frying typically requires longer cooking times due to uneven heat distribution, often taking 10-15 minutes to cook a standard portion. Infrared frying uses radiant heat to cook food faster, reducing cooking time to around 7-10 minutes.

Infrared frying achieves higher surface temperatures quickly, leading to faster browning and crisping of food. Skillet frying relies on direct contact heat, which heats unevenly and may require flipping to ensure even cooking. This difference results in infrared frying consistently outperforming skillet frying in overall cooking time efficiency.

Flavor and Texture Differences

Skillet frying creates a rich, caramelized flavor and crispy texture due to direct contact with hot oil, enhancing Maillard reactions. Infrared frying offers more even heat distribution, resulting in a tender interior while maintaining a delicate crispness on the surface. Flavor intensity tends to be more pronounced in skillet frying, whereas infrared frying preserves subtle natural food flavors and moisture.

Oil Usage and Health Considerations

Skillet frying typically requires a larger amount of oil to prevent sticking and achieve even cooking, which can lead to higher calorie intake. Infrared frying uses less oil by cooking food with direct infrared heat, making it a healthier alternative with reduced fat absorption.

- Oil Consumption - Skillet frying demands more oil, increasing the fat content of the cooked food.

- Health Impact - Infrared frying reduces oil usage, lowering calorie and fat intake for better heart health.

- Cooking Efficiency - Infrared frying provides even heat distribution, minimizing oil degradation and harmful compound formation.

Energy Efficiency and Cost

Skillet frying typically consumes more energy due to prolonged preheating and uneven heat distribution, increasing cooking time and overall cost. Infrared frying offers higher energy efficiency by directly heating the food surface, reducing both energy usage and cooking time.

- Energy Use - Skillet frying relies on conduction through a metal surface, which takes longer to heat and retains heat inefficiently.

- Cost Efficiency - Infrared frying reduces fuel or electricity consumption, lowering operational costs over time.

- Heating Speed - Infrared fryers heat instantly, optimizing energy consumption and minimizing waste.

Infrared frying is generally the more cost-effective and energy-efficient choice compared to traditional skillet frying methods.

Cleaning and Maintenance

Skillet frying often requires thorough scrubbing to remove grease and food residue, making cleaning more time-consuming. Infrared frying features a less oily cooking process, resulting in easier maintenance and quicker wipe-downs.

- Grease buildup - Skillets accumulate oil and charred bits, requiring soaking and scrubbing after each use.

- Surface material - Non-stick and cast iron skillets need specialized care to preserve seasoning and coating.

- Infrared fryer design - Infrared fryers use radiant heat that minimizes oil splatter and reduces residue, simplifying cleanup.

Related Important Terms

Skillet Maillard Dynamics

Skillet frying leverages direct contact heat to induce Maillard reactions rapidly on food surfaces, producing complex flavors and a crispy texture through precise temperature control and even heat distribution. Infrared frying relies on radiant heat, which can achieve high temperatures quickly but may result in uneven Maillard browning compared to the consistent searing dynamics of a skillet.

Infrared Surface Penetration

Infrared frying offers superior surface penetration by directly heating the food's interior through infrared radiation, resulting in faster and more even cooking compared to traditional skillet frying which relies on conductive heat transfer primarily at the surface. This deeper heat penetration in infrared frying reduces cooking time, enhances moisture retention, and improves texture by minimizing surface overcooking and promoting uniform temperature distribution.

Contact Heat Searing

Skillet frying delivers intense contact heat searing by directly applying a hot metal surface to food, creating a rich Maillard reaction and crispy crusts essential for flavor development. Infrared frying utilizes radiant heat transfer without direct contact, offering even searing while minimizing oil absorption and promoting faster cooking times.

Radiant Frying Efficiency

Skillet frying relies on direct heat conduction through the metal surface, often causing uneven temperature distribution and longer cooking times, whereas infrared frying utilizes radiant heat to penetrate food more evenly, enhancing cooking speed and energy efficiency. Infrared frying's ability to emit consistent radiant heat reduces oil absorption and preserves food texture, making it a more efficient method in terms of energy consumption and cooking quality.

Fat Retention Gradient

Skillet frying typically results in higher fat absorption due to direct contact between food and hot oil, creating a significant fat retention gradient in the crust. Infrared frying uses radiant heat to cook food more evenly and reduce oil uptake, leading to lower fat retention and a healthier cooking outcome.

Non-Conductive Frying Plate

Non-conductive frying plates in skillet frying provide even heat distribution without hot spots, preserving food texture and preventing burning. Infrared frying, utilizing radiant heat, achieves faster cooking times and enhanced flavor retention while minimizing oil absorption for healthier meals.

Direct vs Indirect Crisping

Skillet frying delivers direct crisping by applying high heat through direct contact with the pan's surface, creating a golden, textured crust on food. Infrared frying uses indirect crisping by emitting radiant heat that cooks food evenly and quickly, reducing oil absorption while maintaining a crispy exterior.

Oil-Free Fry Signature

Skillet frying traditionally requires oil to prevent sticking and achieve even cooking, while infrared frying utilizes high-frequency infrared waves to cook food without oil, preserving natural flavors and reducing calories. Infrared frying offers a healthier, oil-free fry signature by promoting crisp textures and faster heat transfer, making it an innovative alternative to conventional skillet frying methods.

Pan Thermal Inertia

Skillet frying relies heavily on the pan's thermal inertia, which allows consistent heat retention and even cooking but may result in slower temperature recovery between batches. Infrared frying uses rapid, direct heat emission that minimizes thermal inertia effects, enabling faster temperature adjustments and potentially healthier cooking with less oil absorption.

Skillet Frying vs Infrared Frying for Cooking. Infographic

cookingdiff.com

cookingdiff.com