Aluminum frying pans heat quickly and offer excellent heat conduction, but they can react with acidic foods, potentially altering flavor and causing discoloration. Anodized aluminum frying pans provide a harder, non-reactive surface that resists scratches and corrosion, making them more durable and safer for frying a variety of ingredients. Choosing anodized aluminum ensures even heat distribution while maintaining food quality and pan longevity.

Table of Comparison

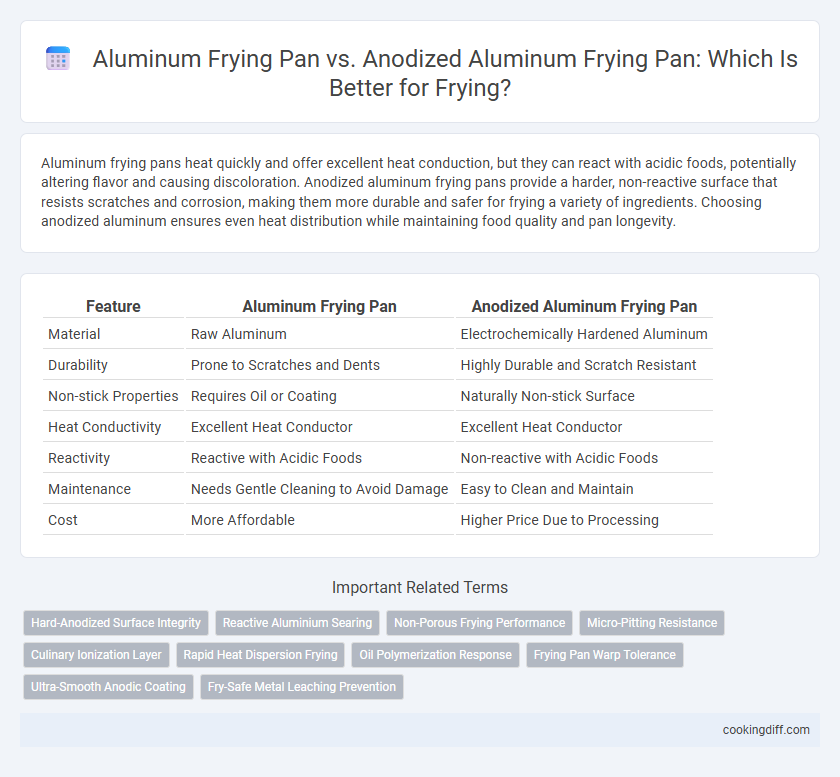

| Feature | Aluminum Frying Pan | Anodized Aluminum Frying Pan |

|---|---|---|

| Material | Raw Aluminum | Electrochemically Hardened Aluminum |

| Durability | Prone to Scratches and Dents | Highly Durable and Scratch Resistant |

| Non-stick Properties | Requires Oil or Coating | Naturally Non-stick Surface |

| Heat Conductivity | Excellent Heat Conductor | Excellent Heat Conductor |

| Reactivity | Reactive with Acidic Foods | Non-reactive with Acidic Foods |

| Maintenance | Needs Gentle Cleaning to Avoid Damage | Easy to Clean and Maintain |

| Cost | More Affordable | Higher Price Due to Processing |

Introduction to Aluminum vs Anodized Aluminum Frying Pans

Aluminum frying pans are popular for their excellent heat conductivity and lightweight design. Anodized aluminum pans feature a chemically treated surface, enhancing durability and resistance to corrosion.

- Heat Conductivity - Aluminum pans offer rapid and even heating for efficient frying.

- Durability - Anodized aluminum pans resist scratches and warping better than raw aluminum.

- Non-reactivity - The anodized layer prevents aluminum from reacting with acidic foods during cooking.

Choosing between aluminum and anodized aluminum pans depends on the balance between affordability and long-lasting performance.

Material Composition: What Sets Them Apart?

Aluminum frying pans consist of pure aluminum, offering excellent heat conductivity and lightweight handling. Anodized aluminum frying pans undergo an electrochemical process that hardens the surface, enhancing durability and corrosion resistance.

The key difference lies in material composition: standard aluminum pans are softer and prone to scratches and oxidation, while anodized versions feature a thicker oxide layer that prevents wear and improves non-stick properties. This anodized layer provides a tougher cooking surface, reducing the likelihood of metal leaching into food. As a result, anodized aluminum pans are preferred for long-term use and healthier frying experiences.

Heat Conductivity: Which Pan Fries Better?

Aluminum frying pans offer excellent heat conductivity, ensuring quick and even cooking, but they may warp or discolor over time. Anodized aluminum frying pans enhance this by providing a harder, non-reactive surface that preserves the pan's heat distribution while increasing durability. For frying, anodized aluminum pans maintain consistent heat better under high temperatures, leading to superior frying performance and food browning.

Durability and Scratch Resistance

Aluminum frying pans offer good heat conductivity but are prone to scratching and denting over time. Anodized aluminum pans provide enhanced durability and superior scratch resistance due to their treated surface.

- Durability - Anodized aluminum pans have a harder surface that resists warping and corrosion better than regular aluminum.

- Scratch Resistance - The anodizing process creates a protective oxide layer that minimizes surface scratches from utensils.

- Longevity - Due to increased hardness and resistance, anodized pans maintain appearance and functionality longer than standard aluminum pans.

Non-Stick Performance for Frying

| Pan Type | Non-Stick Performance | Durability |

|---|---|---|

| Aluminum Frying Pan | Moderate non-stick properties but prone to food sticking without added coatings | Less durable, may warp at high heat, surface can scratch easily |

| Anodized Aluminum Frying Pan | Superior non-stick performance due to a hard, smooth anodized surface that resists sticking | Highly durable, resistant to scratches and corrosion, maintains non-stick qualities longer |

Safety and Toxicity Concerns

Is an anodized aluminum frying pan safer than a regular aluminum pan when it comes to toxicity? Anodized aluminum pans have a hard, non-reactive surface that prevents aluminum from leaching into food, reducing potential health risks associated with aluminum exposure. Regular aluminum pans may release trace amounts of aluminum, especially when cooking acidic foods, raising safety concerns for long-term use.

Ease of Cleaning and Maintenance

Aluminum frying pans tend to require more careful cleaning to avoid surface scratches and discoloration, while anodized aluminum pans offer a more durable, non-porous surface that resists staining and is easier to maintain. The anodization process significantly enhances the pan's resistance to corrosion and wear, resulting in less frequent deep cleaning needs.

- Aluminum Pans Are Prone to Scratches - Regular use can cause surface damage that traps food residues, complicating cleaning.

- Anodized Aluminum Provides a Harder Surface - This makes wiping off burnt or stuck food easier without damaging the pan.

- Maintenance Frequency Differs - Anodized pans require less aggressive cleaning agents, preserving their finish longer than standard aluminum pans.

Price Comparison and Value for Money

Aluminum frying pans generally cost less, making them a budget-friendly choice for everyday cooking purposes. Their lightweight design offers decent heat conduction but often lacks durability compared to more specialized options.

Anodized aluminum frying pans are priced higher due to their enhanced non-stick surface and increased resistance to scratches and corrosion. This adds long-term value by reducing the need for frequent replacements and improving cooking performance.

Best Use Cases for Each Pan

Aluminum frying pans are ideal for quick, even heat distribution, making them perfect for sauteing vegetables and frying eggs at moderate temperatures. Their lightweight design ensures easy handling during fast cooking tasks.

Anodized aluminum frying pans offer enhanced durability and non-stick properties, suited for high-heat searing and cooking acidic foods without reacting. Their scratch-resistant surface makes them excellent for frequent use and longer-lasting performance in busy kitchens.

Related Important Terms

Hard-Anodized Surface Integrity

Hard-anodized aluminum frying pans feature a chemically reinforced surface that provides superior scratch resistance and enhanced corrosion protection compared to standard aluminum pans, ensuring long-lasting durability during high-heat frying. This hard-anodized surface maintains integrity under frequent use, preventing warping and preserving non-stick performance for optimal cooking results.

Reactive Aluminium Searing

Anodized aluminum frying pans offer a non-reactive, durable surface ideal for searing, preventing the metallic taste and discoloration common with standard aluminum pans that react with acidic or alkaline foods during frying. The hard, oxide layer in anodized pans enhances heat distribution and maintains food flavor integrity, making them superior for high-temperature searing tasks.

Non-Porous Frying Performance

Anodized aluminum frying pans offer superior non-porous frying performance due to their hard, corrosion-resistant surface, preventing food from sticking and ensuring even heat distribution. In contrast, regular aluminum pans have a softer, more porous surface that may absorb oils and flavors, leading to uneven cooking and potential staining over time.

Micro-Pitting Resistance

Anodized aluminum frying pans offer superior micro-pitting resistance compared to standard aluminum pans, enhancing durability and preventing surface degradation during high-heat frying. This treatment creates a harder, more corrosion-resistant surface, reducing the risk of tiny pits that can harbor bacteria and affect cooking performance.

Culinary Ionization Layer

Aluminum frying pans offer excellent heat conductivity but lack the durable culinary ionization layer present in anodized aluminum frying pans, which enhances non-stick properties and resists corrosion. The anodized aluminum frying pan's ionized surface provides a harder, more scratch-resistant cooking area ideal for even frying and longer-lasting performance.

Rapid Heat Dispersion Frying

Anodized aluminum frying pans offer superior rapid heat dispersion compared to standard aluminum pans due to their hardened surface, ensuring even cooking and preventing hot spots during frying. This enhanced thermal conductivity allows for precise temperature control, making anodized aluminum pans ideal for quick and consistent frying results.

Oil Polymerization Response

Anodized aluminum frying pans exhibit superior resistance to oil polymerization compared to standard aluminum pans, resulting in less sticky residue and easier cleaning after frying. This enhanced surface durability maintains pan integrity at high frying temperatures, preventing harmful buildup and extending cookware lifespan.

Frying Pan Warp Tolerance

Anodized aluminum frying pans offer superior warp tolerance compared to standard aluminum frying pans due to their harder oxide layer, which enhances structural integrity under high heat. This increased resistance to warping ensures even heat distribution and prolongs the lifespan of the pan during frequent frying tasks.

Ultra-Smooth Anodic Coating

Anodized aluminum frying pans feature an ultra-smooth anodic coating that enhances durability, prevents corrosion, and offers superior non-stick properties compared to regular aluminum frying pans. This coating also ensures even heat distribution, reducing hotspots for more consistent frying results and easier food release.

Aluminum Frying Pan vs Anodized Aluminum Frying Pan for Frying Infographic

cookingdiff.com

cookingdiff.com