Nonstick pans offer easy release and quick cleanup, making them ideal for frying delicate items like eggs or fish without sticking. Ceramic-coated frypans provide a more natural, chemical-free surface that can withstand higher temperatures and resist scratching better than traditional nonstick coatings. Both options enhance frying efficiency, but ceramic coatings generally offer greater durability and are a healthier choice for everyday cooking.

Table of Comparison

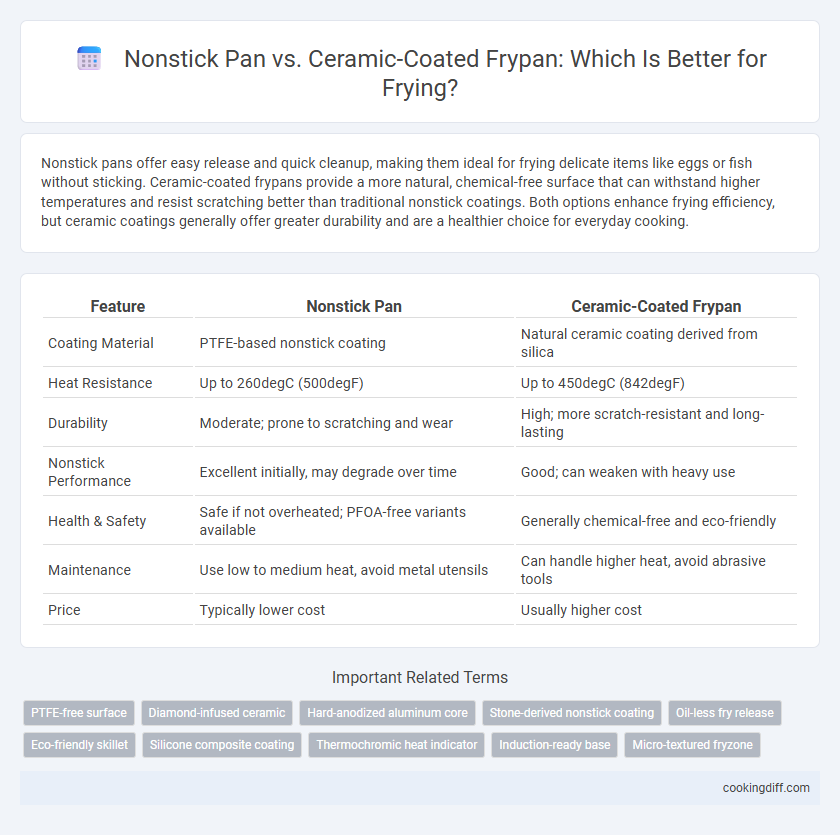

| Feature | Nonstick Pan | Ceramic-Coated Frypan |

|---|---|---|

| Coating Material | PTFE-based nonstick coating | Natural ceramic coating derived from silica |

| Heat Resistance | Up to 260degC (500degF) | Up to 450degC (842degF) |

| Durability | Moderate; prone to scratching and wear | High; more scratch-resistant and long-lasting |

| Nonstick Performance | Excellent initially, may degrade over time | Good; can weaken with heavy use |

| Health & Safety | Safe if not overheated; PFOA-free variants available | Generally chemical-free and eco-friendly |

| Maintenance | Use low to medium heat, avoid metal utensils | Can handle higher heat, avoid abrasive tools |

| Price | Typically lower cost | Usually higher cost |

Nonstick vs Ceramic-Coated Frypans: Quick Comparison

Which is better for frying: nonstick or ceramic-coated frypans? Nonstick frypans offer superior food release and require less oil, making them ideal for low-fat cooking. Ceramic-coated frypans provide a more natural, chemical-free surface but may wear faster and need more careful maintenance.

Surface Material: What Sets Frying Performance Apart?

Nonstick pans feature a PTFE-based coating that provides excellent food release and requires less oil for frying, ensuring a smoother cooking experience. Ceramic-coated frypans utilize a silica-based layer that offers higher heat resistance and a more natural, non-toxic surface for frying.

The surface material of nonstick pans tends to degrade faster under high heat, impacting frying performance and durability. Ceramic coatings maintain surface integrity longer but may need more careful maintenance to preserve their nonstick properties.

Heat Distribution and Retention in Frying

Nonstick pans typically offer superior heat retention due to their aluminum cores, which allow even temperature distribution essential for consistent frying. Ceramic-coated frypans excel in rapid heat distribution but may lose heat faster, impacting cooking efficiency during longer frying sessions.

- Heat Distribution - Nonstick pans distribute heat evenly across the surface, reducing hot spots.

- Heat Retention - Ceramic-coated pans tend to cool down quicker once removed from heat, affecting sustained frying.

- Efficiency in Frying - Aluminum-based nonstick pans maintain steady heat, enhancing frying control and food texture.

Oil Usage and Health Considerations

Nonstick pans require less oil due to their superior surface release, making them ideal for low-fat frying and promoting healthier cooking. Ceramic-coated frypans also offer good nonstick properties but often need slightly more oil to prevent sticking, which can impact overall oil usage. Health considerations favor ceramic coatings for their chemical-free, toxin-free surface, while some nonstick pans may release harmful fumes if overheated.

Durability and Lifespan of Each Frying Pan

Nonstick pans typically offer a durable surface that resists food sticking but tend to degrade faster under high heat, usually lasting around 2 to 3 years with regular use. Ceramic-coated frypans boast a more heat-resistant and scratch-resistant surface, often maintaining their nonstick properties for up to 5 years with proper care.

The lifespan of a ceramic-coated frypan is extended due to its inorganic coating, which withstands higher temperatures without breaking down. Nonstick pans made with PTFE coatings are more prone to wear, especially if exposed to metal utensils or harsh cleaning. Choosing ceramic-coated cookware can improve longevity, but both types require gentle maintenance to maximize durability.

Frying Results: Texture, Browning, and Consistency

Nonstick pans excel in producing evenly browned and consistently textured fried foods due to their superior heat distribution and smooth surface. Ceramic-coated frypans offer a slightly crisper texture but may have less uniform browning and occasional hot spots during frying.

- Texture Difference - Nonstick surfaces create tender, moist interiors, while ceramic coatings provide a firmer, crispier crust.

- Browning Efficiency - Nonstick pans promote uniform browning with minimal sticking, enhancing flavor development.

- Consistency in Cooking - Nonstick materials maintain consistent heat, leading to predictable frying results compared to ceramic coatings that can heat unevenly.

Choosing between nonstick and ceramic-coated frypans depends on desired frying outcomes and texture preferences.

Cleaning and Maintenance Differences

Nonstick pans typically require gentle cleaning with soft sponges and mild detergents to preserve their coating and prevent scratches. Avoiding abrasive materials and dishwasher use extends the pan's lifespan and maintains its nonstick properties.

Ceramic-coated frypans are more resistant to scratching and can often withstand dishwasher cleaning, making maintenance easier. However, they still require careful handling to prevent coating degradation and maintain optimal frying performance.

Safety: Chemical Exposure and Coatings

Nonstick pans typically use PTFE-based coatings, which may release harmful fumes if overheated above 500degF, posing risks during high-temperature frying. Ceramic-coated frypans contain no PTFE or PFOA, offering a safer alternative with fewer chemical exposure concerns when cooking at normal frying temperatures. Both options require proper use to minimize health risks, but ceramic coatings generally provide improved safety due to their inert, non-toxic materials.

Price Point and Value for Frying Enthusiasts

| Nonstick Pan | Typically more affordable with a wide price range from budget-friendly to premium brands, offering excellent value for everyday frying tasks due to superior food release and ease of cleaning. |

| Ceramic-Coated Frypan | Generally priced higher than basic nonstick pans; offers enhanced durability and toxin-free cooking, making it a preferred option for frying enthusiasts seeking a balance between health benefits and long-term value. |

Related Important Terms

PTFE-free surface

Ceramic-coated frypans offer a PTFE-free surface that ensures safer high-heat frying without releasing harmful fumes, while nonstick pans typically contain PTFE, which may degrade at higher temperatures. Choosing ceramic-coated pans enhances durability and environmentally conscious cooking, maintaining effective food release and easy cleanup.

Diamond-infused ceramic

Diamond-infused ceramic-coated frypans offer superior heat conductivity and exceptional scratch resistance compared to traditional nonstick pans, making them ideal for high-temperature frying without releasing harmful chemicals. Their enhanced durability and nonstick properties ensure even cooking and effortless food release, outperforming standard nonstick coatings in longevity and performance.

Hard-anodized aluminum core

Frying with a nonstick pan featuring a hard-anodized aluminum core ensures even heat distribution and excellent durability without warping, enhancing cooking performance and longevity. Ceramic-coated frypans with a similar core provide a non-toxic, scratch-resistant surface ideal for healthier frying but often require more delicate care to maintain their coating.

Stone-derived nonstick coating

Stone-derived nonstick coatings in ceramic-coated frypans offer superior heat distribution and durability compared to traditional nonstick pans, enhancing frying performance and reducing the risk of food sticking. These eco-friendly coatings resist high temperatures and scratching, making them ideal for healthier cooking with minimal oil usage.

Oil-less fry release

Ceramic-coated frypans offer superior oil-less fry release due to their naturally smooth surface and non-toxic, chemical-free coating, reducing the need for added fats while promoting healthier cooking. Nonstick pans may provide effective release but often rely on synthetic chemicals like PTFE, which can degrade over time and require careful maintenance to preserve their nonstick properties during frying.

Eco-friendly skillet

Ceramic-coated frypans offer an eco-friendly alternative to traditional nonstick pans, utilizing natural minerals and fewer harmful chemicals in their manufacturing process. These ceramic skillets provide excellent heat distribution and durability while reducing environmental impact through non-toxic, PFOA- and PTFE-free materials.

Silicone composite coating

Silicone composite coatings on nonstick pans offer superior heat resistance and enhanced durability compared to ceramic-coated frypans, ensuring even frying without hot spots. These coatings also provide excellent food release properties while maintaining safer chemical stability at high temperatures, making them ideal for consistent frying performance.

Thermochromic heat indicator

Nonstick pans with thermochromic heat indicators offer precise temperature control by visually signaling optimal frying heat, enhancing cooking accuracy and preventing overheating. Ceramic-coated frypans also feature thermochromic markers but provide a more natural, chemical-free surface while maintaining reliable heat indication for even cooking.

Induction-ready base

Nonstick pans with induction-ready bases typically feature magnetic stainless steel layers, ensuring quick and even heat distribution, while ceramic-coated frypans may lack consistent induction compatibility due to variable base materials. Choosing an induction-ready pan enhances cooking efficiency and maintains a durable frying surface, essential for optimal frying performance.

Nonstick pan vs ceramic-coated frypan for frying. Infographic

cookingdiff.com

cookingdiff.com