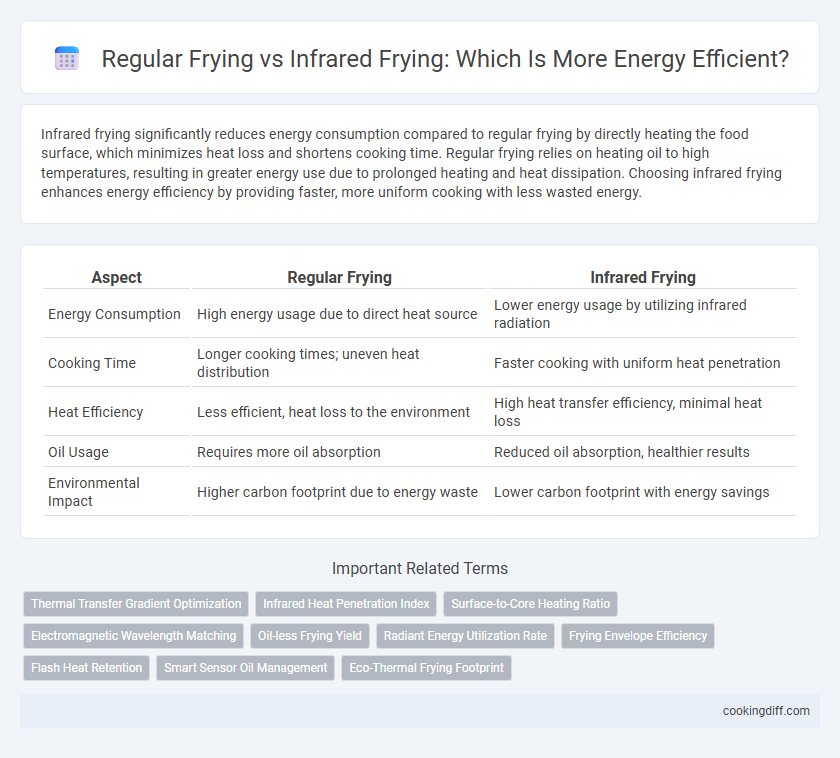

Infrared frying significantly reduces energy consumption compared to regular frying by directly heating the food surface, which minimizes heat loss and shortens cooking time. Regular frying relies on heating oil to high temperatures, resulting in greater energy use due to prolonged heating and heat dissipation. Choosing infrared frying enhances energy efficiency by providing faster, more uniform cooking with less wasted energy.

Table of Comparison

| Aspect | Regular Frying | Infrared Frying |

|---|---|---|

| Energy Consumption | High energy usage due to direct heat source | Lower energy usage by utilizing infrared radiation |

| Cooking Time | Longer cooking times; uneven heat distribution | Faster cooking with uniform heat penetration |

| Heat Efficiency | Less efficient, heat loss to the environment | High heat transfer efficiency, minimal heat loss |

| Oil Usage | Requires more oil absorption | Reduced oil absorption, healthier results |

| Environmental Impact | Higher carbon footprint due to energy waste | Lower carbon footprint with energy savings |

Introduction to Frying Methods: Regular vs Infrared

Regular frying uses direct contact with hot oil to cook food, relying heavily on thermal conduction to transfer heat. Infrared frying employs infrared radiation to heat food more uniformly, reducing oil absorption and cooking time.

Infrared frying provides greater energy efficiency by minimizing heat loss and maintaining consistent temperatures throughout the process. Regular frying typically consumes more energy due to prolonged heating periods and higher oil quantities.

Understanding Energy Consumption in Frying

Regular frying uses conventional heating elements that transfer heat through direct contact with oil, resulting in higher energy loss due to prolonged cooking times. Infrared frying employs radiant heat technology, providing faster heat transfer and reducing overall energy consumption by improving thermal efficiency.

- Heat Transfer Efficiency - Infrared frying achieves quicker surface heating, minimizing energy waste compared to regular frying methods.

- Energy Consumption - Studies show infrared fryers consume up to 30% less energy than traditional fryers while maintaining cooking quality.

- Cooking Time Reduction - Faster heating in infrared frying decreases cooking duration, directly lowering energy use and operational costs.

Optimizing energy consumption in frying processes enhances sustainability and cost-effectiveness in commercial and domestic kitchens.

How Regular Frying Works: A Brief Overview

Regular frying heats oil to cook food through direct contact, relying on convection and conduction to transfer heat. This method consumes significant energy due to prolonged heating times and heat loss to the environment. Infrared frying, by comparison, utilizes radiant heat for faster, more efficient energy transfer with less thermal waste.

The Infrared Frying Process Explained

| Infrared Frying Process | Infrared frying uses radiant heat to cook food by directly transferring energy to the surface, reducing cooking time by up to 30% compared to regular frying. |

| Energy Efficiency | This method consumes approximately 20-25% less energy, as it minimizes heat loss and requires lower oil temperatures. |

| Benefits Over Regular Frying | Infrared frying leads to faster heat penetration and less oil absorption, improving overall energy use and food quality. |

Comparing Cooking Times: Regular vs Infrared Frying

Infrared frying significantly reduces cooking times compared to regular frying by directly heating the food surface. This method promotes faster heat transfer and energy efficiency, leading to quicker meal preparation.

- Regular frying - Typically requires longer cooking times due to indirect heat conduction through oil.

- Infrared frying - Uses radiant heat to cook food faster by penetrating the surface more efficiently.

- Energy efficiency - Infrared frying consumes less energy overall by shortening cooking durations and minimizing heat loss.

Heat Transfer Efficiency in Regular and Infrared Frying

How does heat transfer efficiency differ between regular frying and infrared frying? Regular frying relies on convection and conduction, leading to moderate heat transfer efficiency as heat passes through the oil before reaching the food. Infrared frying uses radiant heat waves that directly penetrate the food surface, resulting in higher energy efficiency and faster cooking times.

Energy Usage Metrics: Which Method Consumes Less?

Regular frying typically consumes more energy due to longer heating times and uneven heat distribution, leading to higher electricity or gas usage. Infrared frying uses radiant heat to cook food faster and more evenly, significantly reducing overall energy consumption.

Energy usage metrics show infrared frying can decrease energy consumption by up to 30% compared to conventional methods. This efficiency results from direct heat transfer to the food surface, minimizing heat loss to the surrounding environment. Consequently, infrared frying not only lowers energy bills but also reduces the carbon footprint of cooking processes.

Impact on Food Quality and Consistency

Regular frying often results in uneven cooking and inconsistent texture due to direct oil contact and fluctuating temperatures, which can degrade food quality. Infrared frying provides more uniform heat distribution, maintaining food moisture and enhancing crispness for better consistency.

Infrared frying reduces oil absorption, leading to healthier and less greasy food while preserving flavor and appearance. Consistent temperature control in infrared frying minimizes overcooking and ensures a reliable outcome for each batch.

Real-World Energy Cost Savings

Regular frying typically consumes more energy due to prolonged heating times and constant oil temperature maintenance, leading to higher electricity or gas bills. Infrared frying uses targeted heat radiation, significantly reducing cooking time and energy usage, which translates to real-world energy cost savings of up to 30%. Businesses and households can benefit from lower utility expenses while maintaining consistent frying quality with this innovative technology.

Related Important Terms

Thermal Transfer Gradient Optimization

Infrared frying enhances energy efficiency by utilizing direct thermal radiation to create a uniform thermal transfer gradient, minimizing heat loss compared to regular frying where conduction and convection cause uneven temperature distribution. This optimized thermal gradient reduces cooking time and energy consumption while maintaining consistent food quality.

Infrared Heat Penetration Index

Infrared frying demonstrates superior energy efficiency compared to regular frying due to its higher Infrared Heat Penetration Index, which ensures deeper and faster heat transfer within food. This enhanced penetration minimizes cooking time and energy consumption while maintaining optimal frying quality.

Surface-to-Core Heating Ratio

Infrared frying achieves a higher surface-to-core heating ratio compared to regular frying, resulting in faster heat penetration and reduced cooking time. This efficiency decreases overall energy consumption by minimizing heat loss and optimizing heat transfer to the food's core.

Electromagnetic Wavelength Matching

Infrared frying offers superior energy efficiency by utilizing electromagnetic wavelengths that closely match the absorption spectrum of cooking oils, resulting in faster and more uniform heat transfer compared to regular frying methods. This precise wavelength matching minimizes energy loss and reduces cooking time, enhancing overall frying performance while conserving energy.

Oil-less Frying Yield

Infrared frying significantly enhances oil-less frying yield by directly heating food through infrared radiation, resulting in faster moisture evaporation and reduced oil absorption compared to regular frying methods. This energy-efficient technique minimizes oil usage while maintaining crispy texture, cutting energy consumption by up to 30% versus conventional deep frying processes.

Radiant Energy Utilization Rate

Infrared frying achieves a higher radiant energy utilization rate compared to regular frying, resulting in more efficient heat transfer and reduced energy consumption. The superior wavelength-specific radiation of infrared frying promotes rapid surface heating, minimizing energy loss and improving overall frying efficiency.

Frying Envelope Efficiency

Regular frying typically exhibits lower frying envelope efficiency due to significant heat loss through conduction and convection, resulting in higher energy consumption. Infrared frying enhances frying envelope efficiency by directly transferring infrared radiation energy to the food surface, minimizing heat loss and reducing overall energy use.

Flash Heat Retention

Regular frying loses significant heat to the surrounding environment due to open oil surfaces, resulting in lower energy efficiency, while infrared frying enhances flash heat retention by using targeted radiant energy to maintain consistent high temperatures quickly. This precise heat delivery minimizes heat loss, reduces cooking time, and lowers overall energy consumption compared to conventional frying methods.

Smart Sensor Oil Management

Regular frying consumes significantly more energy due to prolonged heating times and frequent oil replacement, whereas infrared frying utilizes smart sensor oil management systems to monitor oil quality in real-time, reducing energy waste and extending oil life. This sensor-driven approach optimizes frying temperature and timing, ensuring consistent food quality while minimizing overall energy consumption.

Regular Frying vs Infrared Frying for energy efficiency. Infographic

cookingdiff.com

cookingdiff.com