Oven frying offers even heat distribution and the ability to cook large batches with minimal oil, promoting a healthier cooking method. Halogen frying provides rapid heating through intense infrared radiation, resulting in faster cooking times and crispier textures. Both equipment types optimize energy efficiency, but halogen frying excels in speed, while oven frying benefits from versatility and consistent temperature control.

Table of Comparison

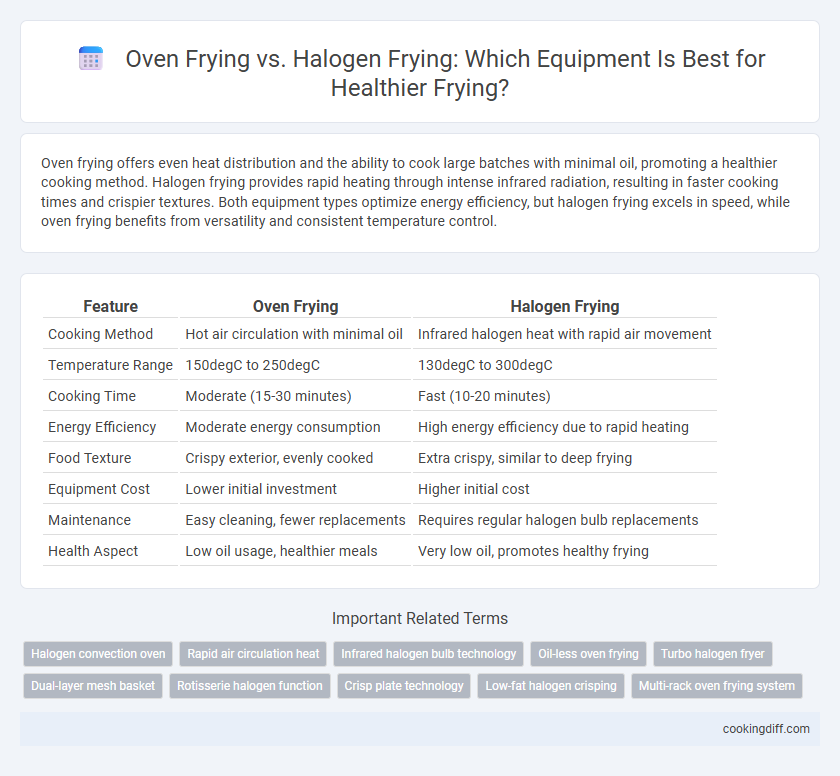

| Feature | Oven Frying | Halogen Frying |

|---|---|---|

| Cooking Method | Hot air circulation with minimal oil | Infrared halogen heat with rapid air movement |

| Temperature Range | 150degC to 250degC | 130degC to 300degC |

| Cooking Time | Moderate (15-30 minutes) | Fast (10-20 minutes) |

| Energy Efficiency | Moderate energy consumption | High energy efficiency due to rapid heating |

| Food Texture | Crispy exterior, evenly cooked | Extra crispy, similar to deep frying |

| Equipment Cost | Lower initial investment | Higher initial cost |

| Maintenance | Easy cleaning, fewer replacements | Requires regular halogen bulb replacements |

| Health Aspect | Low oil usage, healthier meals | Very low oil, promotes healthy frying |

Introduction to Oven Frying and Halogen Frying Equipment

| Frying Method | Equipment Type | Heat Source | Energy Efficiency | Food Texture Outcome |

|---|---|---|---|---|

| Oven Frying | Conventional Oven or Convection Oven | Electric or Gas Heating Elements | Moderate - uses hot air circulation | Crisp exterior with evenly cooked interior |

| Halogen Frying | Halogen Oven with Halogen Bulb | Infrared Halogen Light | High - rapid heating and shorter cooking times | Very crispy results with quick cooking |

Key Differences Between Oven Frying and Halogen Frying Machines

Oven frying and halogen frying machines offer distinct approaches to cooking with varying heat sources and efficiency levels. Understanding these differences helps in selecting the right equipment based on cooking needs and energy consumption.

- Heat Source - Oven frying uses electric or gas heating elements for indirect heat, while halogen frying relies on halogen bulbs emitting infrared radiation for rapid heating.

- Cooking Time - Halogen fryers typically cook food faster due to intense radiant heat, whereas oven fryers require longer cooking periods to achieve similar results.

- Energy Efficiency - Halogen frying machines generally consume less energy by quickly reaching target temperatures, compared to oven fryers that maintain prolonged heating cycles.

Choosing between oven and halogen frying depends on desired cooking speed, energy usage, and heat distribution preferences.

Energy Efficiency: Halogen Fryers vs. Traditional Ovens

Halogen fryers utilize infrared radiation to cook food quickly, resulting in significantly lower energy consumption compared to traditional ovens. Their efficient heat transfer minimizes cooking time, which reduces overall electricity usage by up to 40% in commercial kitchens. Traditional ovens rely on prolonged convection heating, making them less energy-efficient for frying applications.

Cooking Speed Comparison: Oven Fryers vs. Halogen Fryers

Which cooking method heats food faster, oven frying or halogen frying? Halogen fryers utilize infrared radiation, enabling them to cook food more quickly and evenly compared to traditional oven fryers. Oven fryers generally require longer preheating times and extended cooking durations due to slower heat transfer mechanisms.

Equipment Size and Kitchen Space Considerations

Oven frying equipment generally occupies a larger footprint compared to halogen frying machines, requiring more kitchen space due to its bulky design and integrated heating elements. Halogen fryers are compact, enabling efficient use of limited kitchen areas while still delivering rapid cooking times.

Choosing oven frying equipment necessitates ample room for ventilation and heat dissipation, impacting kitchen layout planning significantly. Halogen frying units offer flexibility with smaller dimensions, making them ideal for kitchens prioritizing space optimization and mobility.

Maintenance and Cleaning: Oven Fryers vs. Halogen Fryers

Oven fryers typically require less frequent maintenance due to their sealed cooking environment, which prevents oil splatters and reduces residue buildup. Cleaning is straightforward as most oven fryer components are dishwasher-safe or easily wiped down.

Halogen fryers demand more rigorous cleaning routines because their exposed heating elements can accumulate grease and food particles, increasing the risk of malfunction. Regular removal of crumb trays and thorough wiping of the halogen bulbs are necessary to maintain efficiency. Proper maintenance extends the lifespan of halogen fryers but requires more time and effort compared to oven fryers.

Safety Features in Oven and Halogen Frying Equipment

Oven frying equipment incorporates advanced heat insulation and automatic shut-off features to prevent overheating and reduce fire hazards, enhancing kitchen safety. Its enclosed cooking environment minimizes oil splatters, lowering the risk of burns and slips.

Halogen frying equipment uses rapid halogen heating elements with built-in temperature controls that ensure precise heat management and prevent accidental overheating. Safety mechanisms often include cool-touch exteriors and overheat protection sensors to safeguard users during operation.

Versatility and Cooking Options for Each Appliance

Oven frying offers versatility through adjustable temperature settings and multiple rack positions, enabling simultaneous cooking of various dishes. Halogen frying uses intense radiant heat for faster cooking but is generally limited to smaller food portions and single-layer frying.

- Oven Frying Versatility - Allows baking, roasting, and grilling with custom temperature controls.

- Halogen Frying Speed - Provides rapid cooking due to concentrated halogen heat elements.

- Cooking Options Limitation - Halogen fryers usually accommodate fewer food items at once compared to ovens.

Cost Analysis: Initial Investment and Long-Term Value

Oven frying typically requires a higher initial investment than halogen frying equipment due to its larger size and advanced technology. However, halogen fryers often deliver lower long-term operational costs through energy efficiency and faster cooking times.

- Initial Cost Difference - Oven fryers generally cost 20-30% more upfront compared to halogen fryers.

- Energy Consumption - Halogen frying reduces energy use by up to 40% compared to conventional oven frying.

- Maintenance and Durability - Oven fryers require less frequent maintenance but have higher repair costs than halogen fryers.

Related Important Terms

Halogen convection oven

Halogen convection ovens utilize infrared halogen lamps to deliver rapid, even heat distribution, enhancing energy efficiency and reducing cooking times in comparison to traditional oven frying. This technology ensures crispier textures and superior moisture retention, making it ideal for healthier frying with less oil.

Rapid air circulation heat

Oven frying and halogen frying both use rapid air circulation heat to cook food evenly without excessive oil, but halogen frying offers faster heat-up times and more precise temperature control due to its infrared heating element combined with convection. Oven frying relies solely on convection fans to circulate hot air, resulting in slightly longer cooking times and less intense crispiness compared to halogen frying.

Infrared halogen bulb technology

Infrared halogen bulb technology in halogen frying provides faster and more even heat distribution compared to traditional oven frying, significantly reducing cooking time while preserving moisture and texture. This equipment leverages intense infrared radiation to achieve crisp, golden results with lower oil usage and improved energy efficiency.

Oil-less oven frying

Oil-less oven frying utilizes hot air circulation to cook food evenly with significantly less fat compared to traditional frying methods, preserving nutritional value and enhancing flavor. Halogen frying employs infrared heat for rapid cooking but often requires additional oils, making oil-less oven frying a healthier and more energy-efficient option for low-fat cooking.

Turbo halogen fryer

Turbo halogen fryers offer rapid cooking with efficient heat distribution through halogen radiation, preserving moisture and reducing oil usage compared to traditional oven frying. This advanced technology ensures faster frying times and enhanced energy efficiency while delivering crispy, evenly cooked foods.

Dual-layer mesh basket

Oven frying with a dual-layer mesh basket allows for even heat distribution and enhanced air circulation, resulting in crispier and healthier food compared to halogen frying, which relies on concentrated infrared light but may produce uneven cooking. The dual-layer mesh design improves fat drainage and reduces oil absorption, optimizing texture and flavor in both cooking methods while maximizing equipment efficiency.

Rotisserie halogen function

Rotisserie halogen ovens use infrared heat combined with a rotating spit, ensuring even cooking and crispy texture without excessive oil, making them more energy-efficient and healthier compared to traditional oven frying. Their compact design with halogen bulbs offers faster preheating and uniform heat distribution, optimizing cooking time and enhancing flavor retention during frying.

Crisp plate technology

Crisp plate technology in oven frying provides even heat distribution, resulting in uniformly crispy textures without excessive oil absorption, enhancing health benefits and flavor retention. Halogen frying, utilizing rapid infrared heat, achieves faster cooking times but may lack the consistent crispness delivered by specialized crisp plate systems designed for optimal heat conductivity and moisture control.

Low-fat halogen crisping

Low-fat halogen crisping ovens utilize intense halogen light to rapidly cook food with minimal oil, resulting in healthier, evenly crisped dishes compared to traditional oven frying. These appliances offer faster cooking times and energy efficiency while preserving texture and flavor through precise temperature control.

Oven frying vs halogen frying for equipment. Infographic

cookingdiff.com

cookingdiff.com