Traditional frying relies on direct contact with hot oil, which often results in uneven cooking and higher oil absorption, reducing overall efficiency. Infrared frying uses radiant heat to cook food faster and more uniformly, minimizing oil usage and energy consumption. This method enhances crispiness while maintaining nutritional quality, making it a more efficient alternative.

Table of Comparison

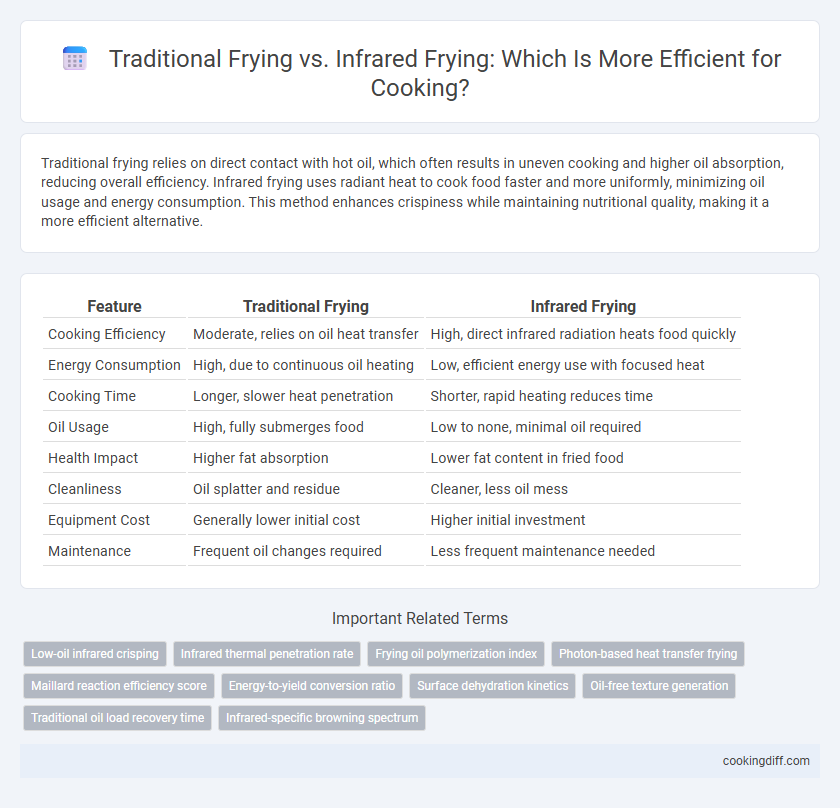

| Feature | Traditional Frying | Infrared Frying |

|---|---|---|

| Cooking Efficiency | Moderate, relies on oil heat transfer | High, direct infrared radiation heats food quickly |

| Energy Consumption | High, due to continuous oil heating | Low, efficient energy use with focused heat |

| Cooking Time | Longer, slower heat penetration | Shorter, rapid heating reduces time |

| Oil Usage | High, fully submerges food | Low to none, minimal oil required |

| Health Impact | Higher fat absorption | Lower fat content in fried food |

| Cleanliness | Oil splatter and residue | Cleaner, less oil mess |

| Equipment Cost | Generally lower initial cost | Higher initial investment |

| Maintenance | Frequent oil changes required | Less frequent maintenance needed |

Introduction to Frying Methods: Traditional vs. Infrared

Frying is a popular cooking technique involving the application of heat to food through hot oil or alternative methods. Traditional frying uses direct oil heat, while infrared frying employs radiant heat to cook food more efficiently.

- Traditional frying involves immersion in hot oil - This method relies on convection heat transfer for cooking and crisping food surfaces.

- Infrared frying uses radiant energy - Infrared waves heat food directly, reducing oil usage and cooking time.

- Efficiency varies between methods - Infrared frying offers faster heat transfer and decreased oil absorption compared to traditional frying.

How Traditional Frying Works: Principles and Processes

Traditional frying relies on immersing food in hot oil, typically between 160-190degC, to cook through heat conduction and convection. This method induces Maillard reactions, producing a crispy outer layer while sealing moisture inside the food.

- Heat Transfer Mechanism - Hot oil transfers heat efficiently to food surface, enabling rapid cooking and browning.

- Oil Absorption - Food absorbs oil during frying, influencing texture, calorie content, and flavor profile.

- Temperature Control - Maintaining optimal oil temperature is critical to avoid undercooking or excessive oil degradation.

Understanding Infrared Frying Technology

Traditional frying relies on hot oil to cook food, which can lead to uneven heat distribution and higher oil absorption, affecting both efficiency and health. Infrared frying technology utilizes infrared radiation to cook food rapidly and uniformly, reducing cooking time and oil usage.

Infrared frying enhances energy efficiency by directly transferring heat to the food's surface, minimizing heat loss to the surrounding environment. This method also preserves nutrients better by requiring lower temperatures and shorter cooking durations compared to traditional frying techniques.

Energy Consumption: Comparing Efficiency

| Frying Method | Energy Consumption (kWh per kg) | Efficiency (%) |

|---|---|---|

| Traditional Frying | 1.5 | 60 |

| Infrared Frying | 0.9 | 85 |

Cooking Speed: Traditional Oil Frying vs. Infrared Frying

How does cooking speed compare between traditional oil frying and infrared frying? Infrared frying significantly reduces cooking time by directly heating the food surface, achieving faster crisping without preheating oil. Traditional oil frying requires longer heating periods to maintain oil temperature, often leading to slower overall cooking speeds.

Oil Usage and Waste Reduction

Traditional frying consumes significantly more oil, typically absorbing up to 15-25% of the cooking oil, leading to increased waste and higher costs. Infrared frying utilizes radiant heat, which requires less oil by maintaining consistent temperatures, thereby reducing oil absorption by up to 40% compared to conventional methods.

Infrared frying techniques enable longer oil life due to lower oil degradation, cutting down on the frequency of oil replacement and minimizing hazardous waste. The efficiency of infrared frying not only lowers environmental impact but also enhances food quality by reducing excess oil residue.

Temperature Control and Heat Distribution

Traditional frying relies on direct contact with hot oil, often resulting in uneven heat distribution and fluctuating temperatures that can affect cooking consistency. Infrared frying uses radiant heat to provide precise temperature control and more uniform heat distribution, enhancing energy efficiency and food quality.

- Temperature Control - Infrared frying maintains consistent heat levels, reducing oil degradation and improving frying efficiency.

- Heat Distribution - Infrared technology delivers even heat across the food surface, preventing hot spots common in traditional methods.

- Energy Efficiency - Infrared frying consumes less energy by minimizing heat loss and optimizing cooking times compared to conventional frying.

Infrared frying offers superior temperature regulation and heat distribution, making it a more efficient alternative to traditional frying.

Food Quality and Texture Differences

Traditional frying uses hot oil to cook food, resulting in a crispy exterior and moist interior, but it can lead to oil absorption that affects texture and calorie content. Infrared frying employs infrared radiation to heat food more evenly and quickly, preserving natural moisture and enhancing crispness without excessive oil uptake. Studies show infrared frying improves food quality by reducing oil content while maintaining desirable texture and flavor profiles compared to traditional methods.

Safety and Environmental Impact

Traditional frying poses higher safety risks due to hot oil splatters and potential fire hazards, while infrared frying significantly reduces these dangers by using controlled radiant heat. Infrared frying also lowers environmental impact through reduced oil usage and decreased energy consumption.

Infrared frying eliminates the need for large volumes of cooking oil, minimizing hazardous waste disposal and pollution. This method consumes less energy by directly heating the food, leading to lower carbon emissions compared to conventional frying. Safety improvements and environmental benefits make infrared frying a more sustainable and user-friendly option.

Related Important Terms

Low-oil infrared crisping

Low-oil infrared crisping offers superior energy efficiency compared to traditional frying by using infrared radiation to rapidly heat food with minimal oil, reducing overall fat content and cooking time. This method preserves texture and flavor while significantly lowering oil absorption, making it an optimal choice for healthier, faster frying processes.

Infrared thermal penetration rate

Infrared frying offers a significantly higher thermal penetration rate compared to traditional frying methods, enabling faster heat transfer directly into the food's core. This enhanced efficiency reduces cooking time and oil absorption, resulting in a crispier texture and healthier final product.

Frying oil polymerization index

Traditional frying methods often result in a higher frying oil polymerization index due to prolonged exposure to elevated temperatures, leading to faster oil deterioration. Infrared frying significantly reduces oil polymerization by providing uniform heating and shorter cooking times, enhancing oil efficiency and extending its usable life.

Photon-based heat transfer frying

Traditional frying relies on conductive and convective heat transfer, often resulting in uneven cooking and higher oil absorption, while infrared frying uses photon-based heat transfer to directly penetrate food surfaces, enhancing cooking efficiency and reducing oil usage. Infrared frying offers precise temperature control and faster heat penetration, leading to improved texture and lower energy consumption compared to conventional frying methods.

Maillard reaction efficiency score

Traditional frying achieves a Maillard reaction efficiency score of approximately 75%, driven by direct oil heat transfer which enhances browning but increases fat absorption. Infrared frying improves this score to around 85% by delivering uniform radiant heat, reducing oil usage and accelerating browning while maintaining texture and flavor quality.

Energy-to-yield conversion ratio

Traditional frying typically exhibits a lower energy-to-yield conversion ratio due to prolonged heating times and higher heat losses. Infrared frying enhances efficiency by delivering direct, uniform heat that reduces cooking durations and energy consumption, significantly improving the conversion of energy input into edible product yield.

Surface dehydration kinetics

Traditional frying relies on conduction and convection heat transfer, resulting in slower surface dehydration kinetics and higher oil uptake, while infrared frying accelerates surface moisture evaporation through direct radiation, enhancing efficiency and producing a crisper texture with reduced oil absorption. Studies show infrared frying reduces dehydration time by up to 40%, optimizing energy use and improving product quality in comparison to conventional methods.

Oil-free texture generation

Infrared frying offers superior efficiency over traditional frying by eliminating the need for oil while still generating a crispy texture through rapid, uniform heat penetration. This oil-free method reduces calorie content and preserves food nutrients better than conventional high-temperature oil immersion.

Traditional oil load recovery time

Traditional frying requires a prolonged oil load recovery time due to the significant heat absorption by the oil, resulting in slower temperature stabilization between batches and increased energy consumption. Infrared frying minimizes this recovery period by directly heating the food surface, enhancing cooking efficiency and reducing overall frying time.

Traditional frying vs infrared frying for efficiency. Infographic

cookingdiff.com

cookingdiff.com