Microwave defrosting rapidly heats frozen proteins by agitating water molecules, offering time efficiency but potential uneven thawing and partial cooking risks. Cryogenic thawing uses ultra-low temperatures to gradually transition proteins from frozen to unfrozen, preserving texture and structural integrity without heat damage. Choosing between methods depends on balancing speed with maintaining protein quality, especially for sensitive or premium products.

Table of Comparison

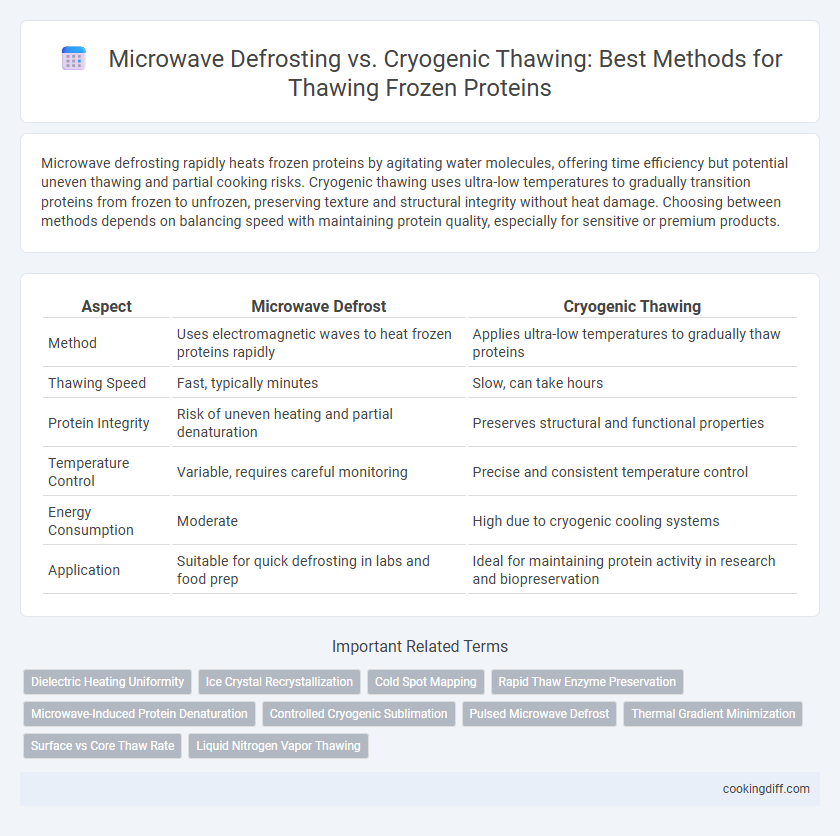

| Aspect | Microwave Defrost | Cryogenic Thawing |

|---|---|---|

| Method | Uses electromagnetic waves to heat frozen proteins rapidly | Applies ultra-low temperatures to gradually thaw proteins |

| Thawing Speed | Fast, typically minutes | Slow, can take hours |

| Protein Integrity | Risk of uneven heating and partial denaturation | Preserves structural and functional properties |

| Temperature Control | Variable, requires careful monitoring | Precise and consistent temperature control |

| Energy Consumption | Moderate | High due to cryogenic cooling systems |

| Application | Suitable for quick defrosting in labs and food prep | Ideal for maintaining protein activity in research and biopreservation |

Introduction to Thawing Methods for Frozen Proteins

Microwave defrost and cryogenic thawing are two prominent methods used for thawing frozen proteins, each with distinct mechanisms and effects on protein integrity. Microwave defrosting utilizes electromagnetic waves to rapidly heat and thaw proteins, while cryogenic thawing relies on controlled temperature increases from extremely low temperatures.

Microwave defrost offers the advantage of speed, often significantly reducing thawing time, which is critical in preserving protein functionality during processing. However, uneven heating and localized overheating can compromise protein structure and activity. Cryogenic thawing, although slower, provides a gentler approach that minimizes thermal shock and maintains molecular stability, making it more suitable for sensitive protein samples.

How Microwave Defrosting Works

How does microwave defrosting work for frozen proteins? Microwave defrosting uses electromagnetic waves to excite water molecules within the protein, generating heat that rapidly thaws the product. This method provides faster thawing compared to cryogenic thawing by directly targeting molecular vibrations without causing ice crystal formation.

Principles of Cryogenic Thawing

Cryogenic thawing utilizes extremely low temperatures, typically involving liquid nitrogen, to rapidly and uniformly thaw frozen proteins without causing thermal shock or denaturation. This method preserves the structural integrity and functionality of proteins by minimizing ice crystal formation and preventing localized overheating common in microwave defrosting. The principle relies on controlled warming rates that maintain protein stability, making cryogenic thawing superior for sensitive biomolecules compared to microwave defrost techniques.

Speed Comparison: Microwave vs. Cryogenic Thawing

| Thawing Method | Average Time for Frozen Proteins | Effect on Protein Integrity |

|---|---|---|

| Microwave Defrost | 2-5 minutes | May cause uneven heating and partial protein denaturation |

| Cryogenic Thawing | 30-60 minutes | Preserves protein structure effectively due to controlled temperature |

Impact on Protein Texture and Quality

Microwave defrosting rapidly thaws frozen proteins but can cause uneven heating, leading to texture degradation and partial protein denaturation. Cryogenic thawing preserves protein integrity by maintaining low temperatures during the thaw, resulting in minimal structural damage and superior quality retention.

- Microwave defrost causes localized overheating - This leads to protein aggregation and negatively affects the texture of the meat.

- Cryogenic thawing maintains uniform low temperatures - This method minimizes ice crystal formation and preserves the original texture.

- Protein quality degradation is higher in microwave thawing - Rapid temperature changes disrupt protein structures more than slow cryogenic processes.

Nutrient Retention in Both Thawing Methods

Microwave defrosting rapidly heats frozen proteins, preserving more water-soluble vitamins but risking uneven temperature distribution that can degrade heat-sensitive nutrients. Cryogenic thawing maintains nutrient integrity by using ultra-low temperatures, minimizing enzymatic activity and oxidation during thawing. Studies show cryogenic methods retain higher levels of essential amino acids and antioxidants compared to microwave defrosting, optimizing nutrient preservation in frozen proteins.

Food Safety Considerations: Avoiding Bacterial Growth

Microwave defrosting rapidly raises the temperature of frozen proteins, minimizing the time food spends in the bacterial growth "danger zone" between 40degF and 140degF. Cryogenic thawing maintains proteins at ultra-low temperatures, preventing bacterial proliferation but requiring additional cooking time after thawing to ensure safety.

- Rapid heating - Microwave defrosting quickly warms proteins, reducing the risk of bacterial growth by limiting time in unsafe temperature ranges.

- Temperature control - Cryogenic thawing keeps proteins below freezing during thawing, inhibiting bacterial activity but potentially prolonging thaw-to-cook intervals.

- Food safety balance - Microwave defrosting demands careful monitoring to avoid partial cooking and uneven heating, which can create bacterial hotspots.

Convenience and Accessibility in the Home Kitchen

Microwave defrosting offers quick and convenient thawing of frozen proteins directly in the home kitchen, reducing overall meal prep time. Cryogenic thawing, while effective, requires specialized equipment and is less accessible for everyday home use.

- Microwave defrosting is widely available - Most kitchens are equipped with microwaves capable of defrosting efficiently without additional tools.

- Cryogenic thawing demands specialized tools - This method typically involves liquid nitrogen or ultra-cold gases, making it impractical for home environments.

- Microwave defrost supports spontaneous cooking - Users can quickly thaw proteins as needed, enhancing flexibility in meal planning.

Microwave defrosting remains the most accessible and convenient option for safely thawing frozen proteins in home kitchens.

Cost and Equipment Requirements

Microwave defrosting offers a cost-effective solution with minimal equipment, typically requiring only a standard microwave oven, making it accessible for most laboratories. The process is rapid but may cause uneven thawing and partial protein denaturation, impacting sample integrity.

Cryogenic thawing requires specialized and expensive equipment such as liquid nitrogen storage and controlled thawing chambers, significantly increasing operational costs. Despite higher expenses, cryogenic thawing provides uniform and gentle thawing, preserving protein structure and functionality more effectively than microwave methods.

Related Important Terms

Dielectric Heating Uniformity

Microwave defrosting utilizes dielectric heating to rapidly raise the temperature of frozen proteins by agitating polar molecules, but often suffers from uneven heating patterns leading to partial thawing and potential protein denaturation. Cryogenic thawing relies on controlled, uniform heat transfer through low-temperature gases or liquids, ensuring consistent thawing and preserving protein structure by minimizing thermal gradients.

Ice Crystal Recrystallization

Microwave defrosting rapidly heats frozen proteins, minimizing ice crystal recrystallization that can cause structural damage, whereas cryogenic thawing involves slow warming that promotes larger ice crystal formation, compromising protein integrity. Controlling ice crystal recrystallization during thawing is critical for preserving the functional properties of frozen proteins in food and biological applications.

Cold Spot Mapping

Microwave defrosting rapidly heats frozen proteins but often creates uneven thawing with cold spots that can promote microbial growth, making cold spot mapping essential for identifying and mitigating these areas. Cryogenic thawing, by contrast, ensures uniform temperature distribution and minimizes cold spot formation, enhancing protein quality and safety through precise thermal control.

Rapid Thaw Enzyme Preservation

Microwave defrosting rapidly thaws frozen proteins by using electromagnetic waves to excite water molecules, minimizing thaw time and preserving enzyme activity through controlled heating. Cryogenic thawing, while slower, maintains enzyme functionality by avoiding thermal stress and preventing protein denaturation during gradual temperature increase.

Microwave-Induced Protein Denaturation

Microwave defrosting rapidly heats frozen proteins, often causing uneven temperature distribution that leads to microwave-induced protein denaturation, altering their structural integrity and functional properties. Cryogenic thawing provides controlled, gradual warming that preserves protein conformation by minimizing thermal stress and preventing the denaturation associated with microwave exposure.

Controlled Cryogenic Sublimation

Controlled cryogenic sublimation offers precise temperature regulation and minimal protein denaturation compared to microwave defrosting, which can cause localized overheating and uneven thawing. This method preserves structural integrity and functional properties of frozen proteins by enabling gradual ice conversion directly to vapor under low temperatures.

Pulsed Microwave Defrost

Pulsed microwave defrosting uses intermittent bursts of microwave energy to selectively target and rapidly thaw frozen proteins, minimizing thermal damage and preserving structural integrity compared to continuous microwave defrosting. This method offers superior control over thawing rates and reduces localized overheating, outperforming cryogenic thawing by accelerating the process without exposure to extreme cold temperatures that can cause protein denaturation.

Thermal Gradient Minimization

Microwave defrosting rapidly reduces ice crystals in frozen proteins but often creates uneven thermal gradients, risking partial denaturation due to localized hotspots. Cryogenic thawing offers superior thermal gradient minimization by uniformly increasing temperature, preserving protein integrity and functionality during the thawing process.

Surface vs Core Thaw Rate

Microwave defrosting rapidly heats the surface of frozen proteins while often leaving the core partially frozen due to uneven energy distribution, resulting in inconsistent thaw rates. Cryogenic thawing, in contrast, provides more uniform core thawing by gradually warming the entire sample, preserving protein integrity and reducing thermal gradients.

Microwave Defrost vs Cryogenic Thawing for frozen proteins Infographic

cookingdiff.com

cookingdiff.com