Microwave defrosting rapidly raises the temperature of frozen meat by agitating water molecules with electromagnetic waves, which can cause uneven thawing and partial cooking. Ultrasonic thawing uses high-frequency sound waves to generate localized heat within the meat, promoting uniform defrosting while preserving texture and moisture retention. Compared to microwave defrosting, ultrasonic thawing offers gentler, more consistent thawing, reducing the risk of bacterial growth and quality degradation.

Table of Comparison

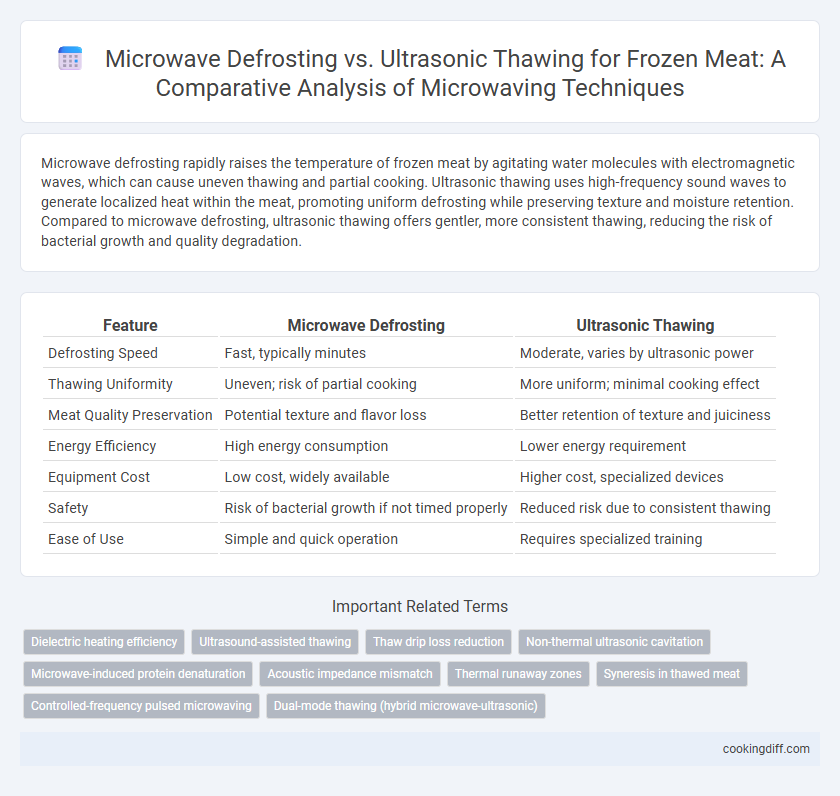

| Feature | Microwave Defrosting | Ultrasonic Thawing |

|---|---|---|

| Defrosting Speed | Fast, typically minutes | Moderate, varies by ultrasonic power |

| Thawing Uniformity | Uneven; risk of partial cooking | More uniform; minimal cooking effect |

| Meat Quality Preservation | Potential texture and flavor loss | Better retention of texture and juiciness |

| Energy Efficiency | High energy consumption | Lower energy requirement |

| Equipment Cost | Low cost, widely available | Higher cost, specialized devices |

| Safety | Risk of bacterial growth if not timed properly | Reduced risk due to consistent thawing |

| Ease of Use | Simple and quick operation | Requires specialized training |

Introduction to Modern Meat Thawing Technologies

| Microwave defrosting leverages electromagnetic waves to rapidly increase the temperature of frozen meat, reducing thawing time significantly compared to conventional methods. Ultrasonic thawing employs high-frequency sound waves to generate microscopic vibrations within the meat, promoting even heat distribution and preserving texture by minimizing cellular damage. Both technologies represent advances in modern meat thawing by enhancing efficiency and maintaining quality, with ultrasonic thawing offering gentler and more uniform thawing, while microwave defrosting provides speed and convenience. |

How Microwave Defrosting Works

Microwave defrosting works by emitting electromagnetic waves that cause water molecules within frozen meat to vibrate, generating heat and accelerating the thawing process. This method heats unevenly, often leading to partial cooking of the outer layers while the interior remains frozen. Ultrasonic thawing, in contrast, uses high-frequency sound waves to uniformly thaw meat without raising the temperature too quickly, preserving texture and quality better than microwave defrosting.

What Is Ultrasonic Thawing?

Ultrasonic thawing employs high-frequency sound waves to generate localized heat, rapidly defrosting frozen meat without partially cooking it. This method preserves meat quality better than microwave defrosting by minimizing temperature gradients and moisture loss.

- Mechanism - Ultrasonic waves cause microscopic vibrations within the meat, producing uniform internal heat.

- Efficiency - It reduces thawing time compared to conventional thawing methods while maintaining texture.

- Quality Preservation - Ultrasonic thawing prevents bacterial growth due to its quick and even warming process.

This innovative technique offers a promising alternative to microwave defrosting for safe, high-quality meat preparation.

Speed Comparison: Microwave vs Ultrasonic Thawing

Microwave defrosting rapidly penetrates frozen meat using electromagnetic waves, reducing thaw time to minutes. Ultrasonic thawing utilizes high-frequency sound waves to generate localized heat, resulting in a more gradual thawing process.

Microwave thawing typically completes within 5-10 minutes for standard meat cuts, while ultrasonic thawing may require 15-30 minutes depending on meat thickness. The speed advantage of microwaves makes them ideal for quick meal preparation, whereas ultrasonic thawing is preferred for preserving meat texture and quality.

Effects on Meat Texture and Quality

Microwave defrosting heats frozen meat unevenly, often causing partial cooking and resulting in a compromised texture with tougher, drier edges. This rapid energy absorption can degrade protein structures and diminish overall meat quality.

Ultrasonic thawing uses high-frequency sound waves to uniformly disrupt ice crystals within the meat, preserving a tender texture and maintaining juiciness. The gentle, controlled process minimizes muscle fiber damage, ensuring superior meat quality compared to microwave methods.

Nutrient Retention in Thawed Meat

Microwave defrosting often leads to uneven thawing, which can cause nutrient loss due to localized overheating. Ultrasonic thawing preserves more nutrients by maintaining a lower, consistent temperature throughout the meat.

- Microwave Defrosting Causes Nutrient Degradation - Exposure to higher temperatures during microwave thawing can degrade heat-sensitive vitamins such as B-complex and Vitamin C.

- Ultrasonic Thawing Maintains Cellular Integrity - The use of ultrasonic waves reduces ice crystal formation, preventing cell rupture and nutrient leakage in frozen meat.

- Greater Retention of Antioxidants - Ultrasonic thawing better preserves antioxidant compounds compared to microwave defrosting, enhancing meat's nutritional quality.

Energy Efficiency: Which Method Uses Less Power?

Microwave defrosting typically consumes more energy due to rapid heating cycles and uneven thawing, leading to frequent power bursts. Ultrasonic thawing uses low-frequency sound waves to generate localized heat, resulting in a more energy-efficient process with consistent thawing. Studies show ultrasonic thawing can reduce power consumption by up to 40% compared to traditional microwave defrosting techniques.

Safety Concerns: Even Thawing and Bacterial Risks

How do microwave defrosting and ultrasonic thawing compare in terms of safety and bacterial risks? Microwave defrosting can cause uneven thawing, leading to partial cooking and the potential growth of harmful bacteria in colder spots. Ultrasonic thawing typically provides more even thawing, reducing bacterial risks by maintaining consistent temperatures throughout the frozen meat.

Cost and Accessibility of Both Methods

Microwave defrosting is generally more cost-effective due to the widespread availability of microwave ovens in households and commercial kitchens. Ultrasonic thawing requires specialized equipment that is less common and typically incurs higher upfront costs.

Microwave defrosting is easily accessible for most consumers, as standard microwaves are a common household appliance. Ultrasonic thawing, while potentially more gentle on meat texture, is mainly found in industrial or research settings and not widely available for everyday use. The higher cost and limited accessibility of ultrasonic devices restrict their use primarily to specialized applications rather than general consumer markets.

Related Important Terms

Dielectric heating efficiency

Microwave defrosting uses dielectric heating by generating electromagnetic waves that cause polar molecules in frozen meat to oscillate, producing internal heat, which results in rapid thawing but can lead to uneven temperature distribution and partial cooking. Ultrasonic thawing enhances dielectric heating efficiency by inducing cavitation and mechanical vibrations that improve heat transfer and water molecule agitation, promoting more uniform defrosting with reduced quality degradation.

Ultrasound-assisted thawing

Ultrasound-assisted thawing uses high-frequency sound waves to accelerate ice crystal melting in frozen meat, preserving texture and minimizing drip loss compared to microwave defrosting. This method enhances thawing uniformity and reduces microbial growth by maintaining lower temperatures throughout the process, making it a superior alternative for maintaining meat quality and safety.

Thaw drip loss reduction

Ultrasonic thawing significantly reduces thaw drip loss in frozen meat by preserving cellular integrity through low-frequency vibrations, compared to microwave defrosting which often causes uneven heating and exacerbates moisture loss. Studies demonstrate ultrasonic thawing decreases drip loss by up to 30%, enhancing meat quality and yield during the thawing process.

Non-thermal ultrasonic cavitation

Non-thermal ultrasonic cavitation in ultrasonic thawing generates microbubbles that implode to break ice crystals in frozen meat, preserving texture and reducing drip loss compared to microwave defrosting, which often causes uneven heating and partial cooking. This method accelerates thawing rates while maintaining meat quality, making it a superior alternative for delicate protein retention and minimizing thermal damage.

Microwave-induced protein denaturation

Microwave defrosting causes rapid heating that can lead to microwave-induced protein denaturation, resulting in altered texture and moisture loss in frozen meat. Ultrasonic thawing employs high-frequency sound waves to gently thaw meat, minimizing protein damage and preserving the meat's structural integrity.

Acoustic impedance mismatch

Microwave defrosting uses electromagnetic waves that heat frozen meat unevenly due to varying water content and density, often leading to partial cooking and texture changes. Ultrasonic thawing exploits acoustic impedance mismatch between ice and meat tissues to generate localized vibrations, resulting in more uniform and quicker defrosting without affecting meat quality.

Thermal runaway zones

Microwave defrosting often creates thermal runaway zones where localized overheating can partially cook the meat while other areas remain frozen, leading to uneven thawing and potential bacterial growth. Ultrasonic thawing provides more uniform energy distribution, minimizing thermal hotspots and preserving the meat's texture by avoiding these critical thermal runaway zones.

Syneresis in thawed meat

Microwave defrosting often causes uneven heating that leads to increased syneresis, resulting in greater water loss and compromised meat texture. Ultrasonic thawing minimizes cell damage by promoting uniform thawing, reducing syneresis and preserving the juiciness and quality of frozen meat.

Controlled-frequency pulsed microwaving

Controlled-frequency pulsed microwaving offers precise energy delivery, reducing hot spots and uneven thawing commonly seen in traditional microwave defrosting of frozen meat. Ultrasonic thawing generates mechanical vibrations that accelerate heat transfer without cooking the meat surface, but controlled-frequency pulsed microwaving is more efficient for uniform thawing while preserving meat texture and moisture content.

Microwave defrosting vs Ultrasonic thawing for frozen meat. Infographic

cookingdiff.com

cookingdiff.com