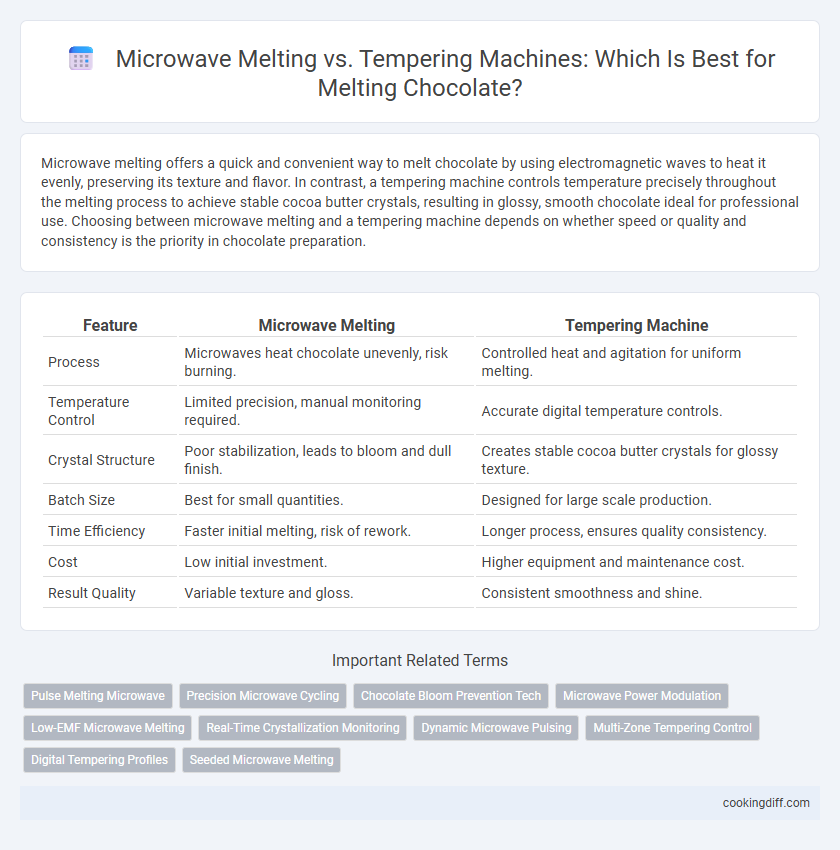

Microwave melting offers a quick and convenient way to melt chocolate by using electromagnetic waves to heat it evenly, preserving its texture and flavor. In contrast, a tempering machine controls temperature precisely throughout the melting process to achieve stable cocoa butter crystals, resulting in glossy, smooth chocolate ideal for professional use. Choosing between microwave melting and a tempering machine depends on whether speed or quality and consistency is the priority in chocolate preparation.

Table of Comparison

| Feature | Microwave Melting | Tempering Machine |

|---|---|---|

| Process | Microwaves heat chocolate unevenly, risk burning. | Controlled heat and agitation for uniform melting. |

| Temperature Control | Limited precision, manual monitoring required. | Accurate digital temperature controls. |

| Crystal Structure | Poor stabilization, leads to bloom and dull finish. | Creates stable cocoa butter crystals for glossy texture. |

| Batch Size | Best for small quantities. | Designed for large scale production. |

| Time Efficiency | Faster initial melting, risk of rework. | Longer process, ensures quality consistency. |

| Cost | Low initial investment. | Higher equipment and maintenance cost. |

| Result Quality | Variable texture and gloss. | Consistent smoothness and shine. |

Introduction to Chocolate Melting Methods

Microwave melting and tempering machines are two common methods used for processing chocolate, each offering distinct advantages. Microwave melting provides rapid and convenient heating by using electromagnetic waves to evenly melt chocolate without direct heat sources. Tempering machines heat and cool chocolate precisely to stabilize cocoa butter crystals, essential for achieving the ideal glossy finish and snap in fine chocolate products.

How Microwaving Melts Chocolate

Microwaving melts chocolate by using electromagnetic waves to excite water molecules, generating heat that evenly softens the chocolate. This method allows for quick melting without direct contact, reducing the risk of burning compared to traditional tempering machines.

- Efficient Heat Transfer - Microwaves penetrate the chocolate, providing uniform heating for consistent melting results.

- Time-Saving Process - Melting chocolate in a microwave significantly cuts down the heating time compared to tempering machines.

- Controlled Temperature - Microwaving enables precise heat adjustments to avoid overheating and preserve chocolate quality.

What is a Tempering Machine?

A tempering machine carefully controls the temperature of melted chocolate to stabilize cocoa butter crystals, ensuring a glossy finish and proper snap. Unlike simple melting methods, it cools and reheats chocolate in precise cycles to achieve optimal texture and durability.

- Temperature Control - Maintains chocolate within exact temperature ranges during heating and cooling phases.

- Crystal Formation - Promotes the formation of stable cocoa butter crystals for uniform texture and sheen.

- Consistent Quality - Produces chocolate with enhanced gloss, snap, and shelf life suitable for confectionery applications.

Comparing Melting Speed: Microwave vs Tempering Machine

| Method | Melting Speed |

|---|---|

| Microwave | Microwaves melt chocolate rapidly, often within 1-3 minutes depending on wattage and quantity, but require frequent stirring to prevent burning. |

| Tempering Machine | Tempering machines melt chocolate more slowly, typically taking 10-20 minutes, ensuring controlled temperature for smooth texture and consistent crystallization. |

Control Over Temperature: Precision Differences

Microwave melting offers rapid heating but lacks precise temperature control, often resulting in uneven chocolate textures due to hotspots. Tempering machines use controlled temperature settings between 82degF and 90degF to ensure consistent crystal formation and optimal gloss in chocolate.

Precision temperature regulation in tempering machines prevents overheating and preserves chocolate viscosity, critical for professional quality products. In contrast, microwaves can surpass ideal melt points quickly, increasing the risk of burning or seizing chocolate during the melting process.

Effects on Chocolate Texture and Shine

Microwave melting rapidly heats chocolate, often leading to uneven texture and dull shine due to inconsistent temperature control. Tempering machines, by contrast, use precise temperature regulation to preserve chocolate's smooth texture and glossy finish.

- Microwave Melting Causes Graininess - Rapid heating can cause chocolate to seize, resulting in a gritty texture.

- Tempering Ensures Crystalline Structure - Controlled cooling promotes stable cocoa butter crystals, enhancing texture and shine.

- Microwave Leads to Matte Appearance - Uneven heat distribution often dulls the chocolate's surface gloss.

Tempering machines produce superior chocolate quality by maintaining consistent texture and high shine essential for professional confectionery.

Impact on Chocolate Flavor and Quality

How does the choice between microwave melting and tempering machines impact chocolate flavor and quality? Microwave melting can cause uneven heating, leading to burnt spots that negatively affect the flavor and texture of chocolate. Tempering machines ensure precise temperature control, preserving the chocolate's glossy finish, snap, and smooth mouthfeel for superior sensory quality.

Best Uses for Microwaving in Chocolate Work

Microwave melting provides fast, even heating ideal for small batches of chocolate, preserving texture and flavor without overheating. This method is best suited for quick tempering and remelting tasks in chocolate work, ensuring smooth consistency.

Tempering machines offer precise temperature control for large-scale chocolate production, enhancing gloss and snap by stabilizing cocoa butter crystals. Microwaving excels in convenience and speed, making it the preferred choice for artisan chocolatiers and home use.

When to Choose a Tempering Machine

Tempering machines are ideal when precise chocolate crystallization is required for a glossy finish and stable texture. They maintain consistent temperatures during the melting process, ensuring professional-quality results.

Choose a tempering machine when producing large batches or high-volume chocolate products to guarantee uniformity. This equipment reduces the risk of overheating and chocolate bloom, common issues in microwaving methods. The controlled environment of a tempering machine streamlines production, making it essential for commercial chocolatiers and confectionery businesses.

Related Important Terms

Pulse Melting Microwave

Pulse Melting Microwave technology offers precise control over temperature and timing, preventing chocolate from overheating and preserving its smooth texture during melting. This method outperforms traditional tempering machines by enabling rapid, uniform heat distribution, which reduces processing time and enhances chocolate quality.

Precision Microwave Cycling

Microwave melting ensures precise temperature control through advanced precision microwave cycling, preventing chocolate from overheating and maintaining optimal texture. Tempering machines utilize controlled microwave pulses to cycle heat accurately, delivering consistent viscosity and sheen critical for quality chocolate production.

Chocolate Bloom Prevention Tech

Microwave melting with advanced chocolate bloom prevention technology ensures uniform heating that preserves the chocolate's crystalline structure, reducing the risk of fat and sugar bloom. Tempering machines, while effective for controlled temperature cycling, may lack the rapid, even heat distribution provided by specialized microwave systems, which minimizes bloom and maintains optimal chocolate texture.

Microwave Power Modulation

Microwave power modulation in chocolate melting ensures precise temperature control to prevent chocolate from burning or seizing, unlike tempering machines that rely on mechanical temperature adjustments. This modulation allows for uniform heat distribution, preserving the chocolate's texture and flavor during melting.

Low-EMF Microwave Melting

Low-EMF microwave melting machines utilize reduced electromagnetic fields to evenly and gently melt chocolate, preserving its texture and flavor integrity compared to traditional tempering machines. These specialized microwaves minimize heat hotspots, resulting in smooth, glossy chocolate with consistent temper ideal for professional confectionery applications.

Real-Time Crystallization Monitoring

Microwave melting machines efficiently soften chocolate by utilizing precise energy control, while tempering machines maintain stable temperature profiles crucial for crystalline structure formation. Real-time crystallization monitoring integrates sensors and feedback mechanisms to optimize crystal phase transitions, ensuring consistent texture and gloss in chocolate production.

Dynamic Microwave Pulsing

Dynamic microwave pulsing in microwave melting machines enhances the precision and consistency of melting chocolate by controlling heat distribution more effectively than tempering machines. This technology reduces overheating risks and preserves chocolate's quality by delivering targeted energy bursts tailored to the chocolate's thermal properties.

Multi-Zone Tempering Control

Multi-zone tempering control in a tempering machine offers precise temperature regulation across different heating zones, ensuring uniform chocolate crystal formation and superior texture. Unlike microwave melting, which often causes uneven heating, multi-zone tempering allows consistent chocolate quality by maintaining stable thermal conditions throughout the entire batch.

Digital Tempering Profiles

Digital tempering profiles in microwave melting vs tempering machines enable precise temperature control essential for chocolate crystallization, ensuring consistent texture and gloss. These profiles automate the delicate process, reducing the risk of overheating and preserving chocolate's quality during both melting and tempering phases.

Microwave Melting vs Tempering Machine for melting chocolate Infographic

cookingdiff.com

cookingdiff.com