Microwaving chocolate offers convenience and speed but risks uneven heating, resulting in burnt spots or seizing. Precision induction provides consistent control over temperature, ensuring smooth, evenly melted chocolate without the risk of overheating. For culinary accuracy and quality, precision induction is superior to microwaving in melting chocolate.

Table of Comparison

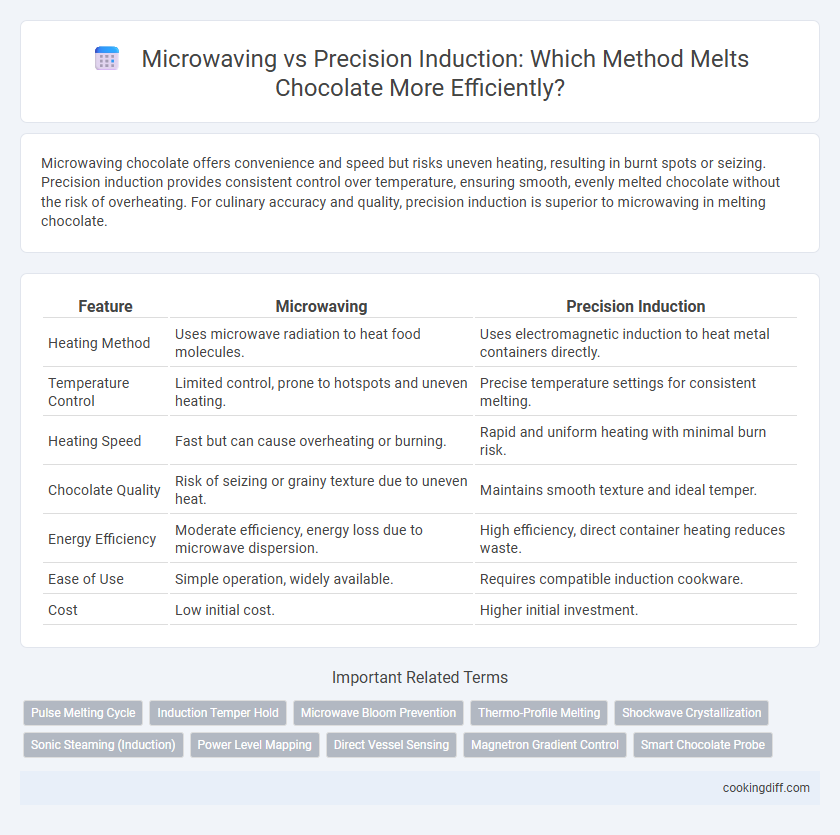

| Feature | Microwaving | Precision Induction |

|---|---|---|

| Heating Method | Uses microwave radiation to heat food molecules. | Uses electromagnetic induction to heat metal containers directly. |

| Temperature Control | Limited control, prone to hotspots and uneven heating. | Precise temperature settings for consistent melting. |

| Heating Speed | Fast but can cause overheating or burning. | Rapid and uniform heating with minimal burn risk. |

| Chocolate Quality | Risk of seizing or grainy texture due to uneven heat. | Maintains smooth texture and ideal temper. |

| Energy Efficiency | Moderate efficiency, energy loss due to microwave dispersion. | High efficiency, direct container heating reduces waste. |

| Ease of Use | Simple operation, widely available. | Requires compatible induction cookware. |

| Cost | Low initial cost. | Higher initial investment. |

Speed and Efficiency: Microwaving vs Precision Induction

Microwaving chocolate offers rapid melting by directly heating the water molecules, but it often results in uneven heat distribution. Precision induction provides controlled, consistent heat, ensuring even melting with less risk of burning.

- Speed - Microwaves heat chocolate quickly within seconds due to direct radiation absorption.

- Efficiency - Precision induction uses electromagnetic fields to maintain precise temperatures, reducing energy waste.

- Control - Induction allows fine temperature adjustments for smooth chocolate melting without hotspots.

Precision induction's superior temperature control enhances melting quality despite slower initial heat-up compared to microwaving.

Temperature Control: Achieving the Perfect Melt

Microwaving chocolate offers quick melting but often results in uneven temperature control, risking scorching or grainy texture. Precision induction melting provides consistent temperature management, ensuring the chocolate melts smoothly without burning.

Precision induction uses electromagnetic fields to maintain exact temperatures ideal for chocolate melting, typically between 104degF and 113degF (40degC and 45degC). This precise control prevents overheating and preserves the chocolate's glossy finish and rich flavor. Microwaving, while convenient, requires frequent stirring and short bursts of heat to avoid temperature spikes that can compromise the final product.

Consistency and Texture in Chocolate Melting

| Microwaving | Can cause uneven heating, leading to inconsistent chocolate texture with potential graininess or burning spots. |

| Precision Induction | Provides uniform temperature control, resulting in consistently smooth, glossy chocolate with ideal texture for tempering. |

Ease of Use: Simplicity of Microwaving vs Induction

Microwaving chocolate involves simple, timer-based heating with intermittent stirring, making it a straightforward method for most users. Precision induction offers controlled, adjustable temperature settings that prevent overheating but requires familiarity with the device's interface.

- Microwaving is widely accessible - Most kitchens have a microwave, allowing immediate use without extra equipment.

- Induction demands technical understanding - Users must manage precise temperature controls to avoid burning chocolate.

- Microwaving benefits from intuitive operation - Setting short bursts and stirring can be done easily without learning curves.

Risk of Chocolate Seizing or Burning

Microwaving chocolate can lead to uneven heating, increasing the risk of seizing or burning due to hot spots. Precision induction offers controlled, consistent temperature regulation, minimizing the likelihood of chocolate damage during melting.

- Microwaving risks - Microwave ovens can create uneven heat distribution, causing chocolate to overheat and seize quickly.

- Precision induction control - Induction cooktops maintain steady, precise temperatures that prevent chocolate from burning or hardening prematurely.

- Chocolate quality preservation - Using precision induction ensures smooth melting and preserves the glossy texture and flavor integrity of chocolate.

Equipment Needed for Each Melting Method

Microwaving chocolate requires only a microwave-safe bowl and a microwave oven, making it a simple and accessible method for most users. Precision induction melting necessitates specialized induction cooktops and compatible cookware designed to evenly distribute heat and control temperature precisely. The difference in equipment highlights microwaving's convenience versus the induction method's focus on temperature accuracy and efficiency.

Suitability for Different Chocolate Types

Microwaving is suitable for melting most common chocolate types, such as milk and semi-sweet, due to its ease and quick heat application. However, it risks uneven heating and burning if not carefully monitored, making it less ideal for delicate chocolates like white or couverture.

Precision induction offers controlled, consistent heat that is perfect for maintaining the integrity of fine chocolates, including dark and specialty varieties. This method reduces the risk of seizing or burning, ensuring a smooth, glossy finish ideal for professional use.

Cleaning and Maintenance After Melting

Microwaving chocolate often results in sticky residue and uneven heating, requiring frequent cleaning of turntables and microwave interiors to prevent buildup and odors. Precision induction melting offers more controlled temperature management, minimizing spills and reducing cleaning frequency and effort. Maintaining induction devices involves wiping smooth surfaces and occasional descaling, making them more convenient for regular chocolate melting tasks.

Energy Consumption and Kitchen Safety

Microwaving chocolate typically consumes more energy due to uneven heating cycles and frequent stirring, which increases overall cooking time. Precision induction heating offers consistent temperature control, resulting in lower energy consumption and faster melting.

Microwaves pose a higher risk of overheating or burning chocolate, increasing kitchen hazards such as steam or splattering. Precision induction systems maintain safe, stable temperatures, minimizing the chance of accidents and ensuring a safer kitchen environment.

Related Important Terms

Pulse Melting Cycle

Pulse melting cycle in microwaving allows controlled bursts of heat to prevent chocolate from scorching, but precision induction offers more consistent temperature regulation for melting chocolate evenly. Induction's targeted energy delivery reduces hot spots and maintains optimal tempering conditions critical for glossy, smooth chocolate finishes.

Induction Temper Hold

Precision induction cooktops maintain a consistent temperature hold ideal for melting chocolate without scorching, providing better control over the delicate process compared to microwaving. Microwaving often heats unevenly, risking hotspots that can seize or burn chocolate, while induction's precise temperature settings ensure smooth, even melting.

Microwave Bloom Prevention

Microwaving chocolate can cause uneven heating, leading to sugar bloom and fat bloom due to rapid temperature fluctuations that disrupt the cocoa butter crystals. Precision induction heating offers controlled and uniform temperature management, effectively preventing bloom by maintaining chocolate within the optimal melting range of 40-45degC (104-113degF).

Thermo-Profile Melting

Microwaving heats chocolate unevenly, causing hot spots and risking burn or seizing due to rapid, uncontrolled temperature spikes. Precision induction offers a controlled thermo-profile melting process that ensures uniform heat distribution and maintains ideal temperature ranges for smooth, consistent chocolate texture.

Shockwave Crystallization

Microwaving chocolate can cause uneven heating, leading to inconsistent melting and crystallization, whereas precision induction offers controlled temperature regulation crucial for managing Shockwave Crystallization, which stabilizes cocoa butter crystals for a smooth, glossy finish. The precise energy pulses from induction promote uniform nucleation and prevent overheating, minimizing grainy textures and preserving chocolate's temper.

Sonic Steaming (Induction)

Sonic Steaming in precision induction melting provides uniform heat distribution, reducing the risk of scorching chocolate compared to variable microwave hotspots. This technology ensures precise temperature control, maintaining chocolate's smooth texture and ideal tempering for culinary precision.

Power Level Mapping

Microwaving chocolate requires careful power level mapping, typically using low or medium settings to prevent overheating and seizing, as uneven energy distribution can cause hotspots. Precision induction offers consistent temperature control and precise power adjustments, ensuring uniform melting without the risk of burning or uneven texture.

Direct Vessel Sensing

Microwaving relies on electromagnetic waves to heat chocolate unevenly, often causing hotspots and potential burning due to lack of precise temperature control. Precision induction with direct vessel sensing uses magnetic fields to heat cookware directly, enabling accurate temperature monitoring and uniform melting, which preserves chocolate quality and texture.

Magnetron Gradient Control

Microwaving relies on magnetron gradient control to generate uneven heat distribution, often causing hotspots and inconsistent melting of chocolate. Precision induction uses targeted electromagnetic fields to maintain uniform temperature, ensuring smoother and controlled chocolate melting without scorching.

Microwaving vs Precision Induction for melting chocolate Infographic

cookingdiff.com

cookingdiff.com