Choosing between a plastic container and a pickle pipe for pickling depends on space, convenience, and flavor infusion. Plastic containers provide a lightweight and versatile option ideal for small batches and easy storage, while pickle pipes offer an innovative airflow system that enhances fermentation by allowing gases to escape without introducing contaminants. For optimal pickling, the choice hinges on balancing durability and the desired fermentation control.

Table of Comparison

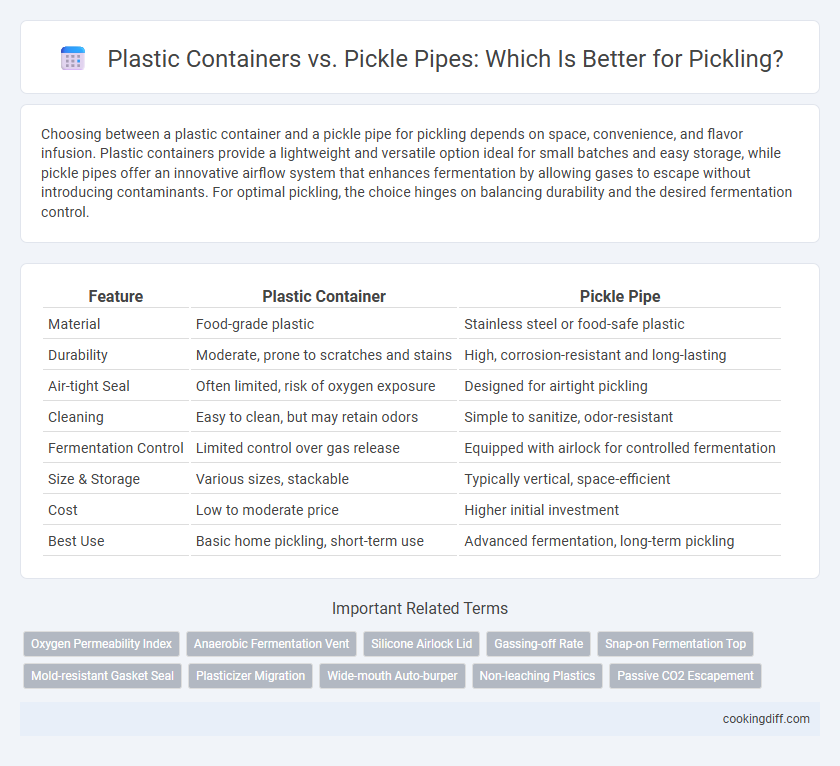

| Feature | Plastic Container | Pickle Pipe |

|---|---|---|

| Material | Food-grade plastic | Stainless steel or food-safe plastic |

| Durability | Moderate, prone to scratches and stains | High, corrosion-resistant and long-lasting |

| Air-tight Seal | Often limited, risk of oxygen exposure | Designed for airtight pickling |

| Cleaning | Easy to clean, but may retain odors | Simple to sanitize, odor-resistant |

| Fermentation Control | Limited control over gas release | Equipped with airlock for controlled fermentation |

| Size & Storage | Various sizes, stackable | Typically vertical, space-efficient |

| Cost | Low to moderate price | Higher initial investment |

| Best Use | Basic home pickling, short-term use | Advanced fermentation, long-term pickling |

Introduction to Pickling Containers

| Plastic Container | Lightweight, affordable, and widely available, plastic containers offer ease of use and minimal risk of corrosion during the pickling process. |

| Pickle Pipe | Specialized stainless steel or PVC pipes designed for optimized brine circulation and durability, enhancing the consistency of fermentation and flavor development. |

| Conclusion | Choosing between plastic containers and pickle pipes depends on scale, durability requirements, and fermentation control, with plastic suited for small batches and pickle pipes ideal for industrial or long-term pickling operations. |

Understanding Plastic Containers in Pickling

Plastic containers are a popular choice for pickling due to their lightweight nature and resistance to corrosion compared to metal alternatives. Food-grade, BPA-free plastics ensure safety by preventing chemical leaching during the acidic fermentation process. These containers are also transparent, allowing easy monitoring of the pickle's color and progress without opening the container.

What is a Pickle Pipe?

A pickle pipe is a specialized fermentation airlock designed to allow gases to escape during the pickling process while preventing oxygen and contaminants from entering. Unlike plastic containers that may require manual burping, pickle pipes automate gas release, maintaining optimal anaerobic conditions for fermentation.

- Gas Release Mechanism - The pickle pipe enables continuous escape of carbon dioxide produced during fermentation to prevent pressure buildup.

- Contamination Prevention - It prevents oxygen and airborne microbes from entering, reducing the risk of mold growth and spoilage.

- Ease of Use - Pickle pipes fit standard fermentation lids, making them a convenient and effective alternative to traditional plastic containers with airlocks.

Benefits of Using Plastic Containers

Plastic containers offer superior durability and resistance to corrosion compared to traditional pickle pipes, making them ideal for long-term pickling processes. Their airtight seals prevent contamination and maintain consistent fermentation environments, crucial for achieving optimal flavor and texture in pickled products. Lightweight and easy to clean, plastic containers enhance convenience and hygiene in both commercial and home pickling setups.

Advantages of Pickle Pipes in Fermentation

Pickle pipes offer enhanced oxygen control, crucial for optimal anaerobic fermentation conditions in pickling processes. Their design allows consistent brine circulation, improving flavor development and texture in fermented vegetables.

- Improved Oxygen Barrier - Pickle pipes minimize oxygen exposure, preventing spoilage and promoting lactic acid bacteria growth.

- Consistent Brine Distribution - Even brine flow ensures uniform fermentation, reducing the risk of uneven pickling.

- Reusable and Durable - Made from food-grade materials, pickle pipes withstand repeated use without contaminating the pickle batch.

Choosing pickle pipes enhances fermentation reliability and product quality compared to conventional plastic containers.

Potential Risks of Plastic Containers

Plastic containers can leach harmful chemicals such as BPA and phthalates into pickling brine, potentially compromising food safety and flavor. The porous nature of some plastics may also harbor bacteria, increasing the risk of contamination during fermentation.

Exposure to heat or acidic environments during pickling can accelerate the breakdown of plastic materials, releasing toxins into preserved foods. Unlike glass or ceramic containers, plastic lacks durability and may warp or crack, leading to leaks and spoilage. Long-term use of plastic containers for pickling heightens the chances of chemical leaching and health hazards.

Pickle Pipe: Hygiene and Safety Aspects

Pickle pipes offer superior hygiene and safety compared to plastic containers due to their non-porous material, which prevents bacterial growth and contamination during the pickling process. Their design ensures consistent fermentation conditions, reducing the risk of spoilage and maintaining food safety standards.

Unlike plastic containers, pickle pipes are resistant to chemical leaching and do not absorb odors or stains, ensuring a safer environment for preserving cucumbers and other vegetables. This makes pickle pipes a preferred choice for maintaining high-quality, safe, and hygienic pickled products.

Flavor and Texture Differences

Plastic containers are non-porous and do not interact with the brine or vegetables, preserving the original flavor but sometimes leading to a less complex taste profile in pickles. The smooth surface of plastic can result in a crisp texture but might lack the slight fermentation nuances that develop in other containers.

Pickle pipes, typically made from ceramic or other porous materials, allow micro-oxygenation during the fermentation process, enhancing the depth and complexity of pickle flavors. This controlled airflow can also contribute to a more tender and evenly fermented texture, making pickles more flavorful and uniquely textured compared to those fermented in plastic containers.

Cost Comparison: Plastic Container vs Pickle Pipe

Which is more cost-effective for pickling: a plastic container or a pickle pipe? Plastic containers typically have lower upfront costs and are widely available, making them accessible for small-scale pickling. Pickle pipes, while more expensive initially, offer durability and reusable features that can reduce long-term expenses.

Related Important Terms

Oxygen Permeability Index

Plastic containers typically have a higher Oxygen Permeability Index (OPI) compared to pickle pipes, which can lead to faster oxidation and spoilage during the pickling process. Using pickle pipes with a lower OPI helps maintain anaerobic conditions, preserving the texture, flavor, and shelf life of pickled products more effectively.

Anaerobic Fermentation Vent

Plastic containers provide an airtight seal essential for anaerobic fermentation vents in pickling, preventing oxygen exposure that causes spoilage. Pickle pipes, designed with built-in airlocks, allow carbon dioxide to escape while maintaining an anaerobic environment, optimizing fermentation and flavor development.

Silicone Airlock Lid

Silicone airlock lids provide a flexible, airtight seal for plastic containers, enhancing fermentation by preventing oxygen exposure while allowing gas release. Compared to traditional pickle pipes, silicone airlock lids offer superior durability, ease of cleaning, and consistent pressure regulation crucial for maintaining ideal pickling conditions.

Gassing-off Rate

Plastic containers generally exhibit a lower gassing-off rate compared to pickle pipes due to their airtight seals, which help retain carbon dioxide during fermentation, enhancing flavor development. In contrast, pickle pipes allow more gas exchange, leading to a higher gassing-off rate that can speed up fermentation but may result in less consistent acidity levels.

Snap-on Fermentation Top

Snap-on fermentation tops provide an airtight seal ideal for plastic containers, preventing oxygen exposure crucial for proper fermentation during pickling. Unlike pickle pipes, these tops allow controlled gas release and reduce contamination risk, enhancing flavor development and preserving crispness in pickled vegetables.

Mold-resistant Gasket Seal

A mold-resistant gasket seal in plastic containers provides a durable barrier against moisture and contaminants, ensuring optimal preservation during pickling compared to traditional pickle pipes. Plastic containers with advanced gasket seals reduce the risk of mold growth by maintaining an airtight environment that supports consistent fermentation conditions.

Plasticizer Migration

Plastic containers are more prone to plasticizer migration during pickling, which can leach harmful chemicals into acidic brines and compromise food safety. In contrast, pickle pipes made from food-grade PVC or polyethylene are designed to minimize plasticizer migration, ensuring safer preservation and maintaining pickle flavor integrity.

Wide-mouth Auto-burper

Wide-mouth auto-burper plastic containers provide airtight sealing and contamination prevention, making them ideal for controlled fermentation during pickling. Compared to traditional pickle pipes, these containers offer ease of use, improved gas release, and consistent flavor retention throughout the pickling process.

Non-leaching Plastics

Non-leaching plastics such as high-density polyethylene (HDPE) and polypropylene (PP) are preferred for pickle pipes due to their chemical resistance and durability, preventing harmful contaminants from leaching into the brine. Plastic containers made from non-leaching materials also provide a safe environment for prolonged pickling, maintaining the integrity and flavor of the pickled product without the risk of chemical migration.

Plastic Container vs Pickle Pipe for pickling. Infographic

cookingdiff.com

cookingdiff.com