A stainless steel strainer offers durability and resistance to high temperatures, making it ideal for handling hot pickling liquids without retaining odors or stains. Fine-mesh nylon strainers provide a delicate filtration that captures smaller particles, ensuring a clearer brine but may absorb flavors and are less heat-resistant. Choosing between them depends on whether you prioritize toughness and heat tolerance with stainless steel or finer filtration with nylon.

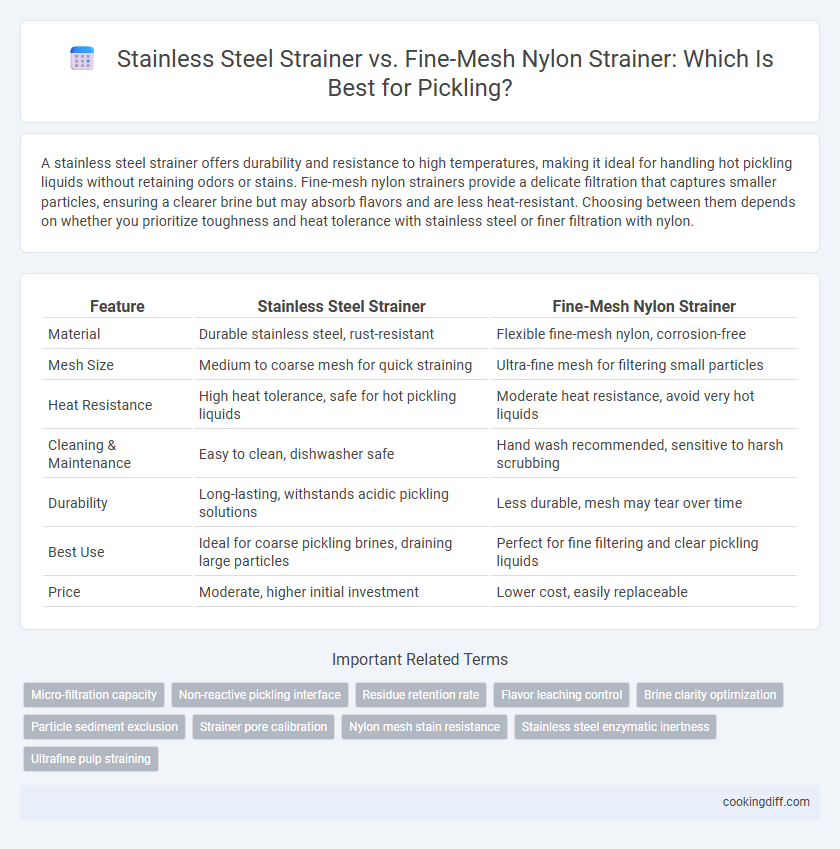

Table of Comparison

| Feature | Stainless Steel Strainer | Fine-Mesh Nylon Strainer |

|---|---|---|

| Material | Durable stainless steel, rust-resistant | Flexible fine-mesh nylon, corrosion-free |

| Mesh Size | Medium to coarse mesh for quick straining | Ultra-fine mesh for filtering small particles |

| Heat Resistance | High heat tolerance, safe for hot pickling liquids | Moderate heat resistance, avoid very hot liquids |

| Cleaning & Maintenance | Easy to clean, dishwasher safe | Hand wash recommended, sensitive to harsh scrubbing |

| Durability | Long-lasting, withstands acidic pickling solutions | Less durable, mesh may tear over time |

| Best Use | Ideal for coarse pickling brines, draining large particles | Perfect for fine filtering and clear pickling liquids |

| Price | Moderate, higher initial investment | Lower cost, easily replaceable |

Introduction: Importance of Strainers in Pickling

Strainers play a crucial role in the pickling process by ensuring the removal of unwanted solids and achieving a clear brine for optimal preservation. Choosing between stainless steel and fine-mesh nylon strainers impacts flavor retention and ease of cleaning.

- Stainless steel strainer durability - Resistant to corrosion and high temperatures, ideal for long-term use in acidic pickling solutions.

- Fine-mesh nylon strainer filtration - Captures smaller particles effectively, enhancing the clarity of the pickling liquid.

- Maintenance and hygiene - Stainless steel strainers are easy to sanitize, while nylon strainers require gentle cleaning to avoid damage.

Material Matters: Stainless Steel vs Fine-Mesh Nylon

Stainless steel strainers offer durability and resistance to acidic pickling brines, ensuring no metallic taste transfer during the pickling process. Fine-mesh nylon strainers provide a lightweight, flexible option that effectively filters small particles but may degrade over time with frequent acid exposure.

- Durability - Stainless steel withstands corrosion and high temperatures better than nylon.

- Filtration - Nylon strainers capture finer particles due to their tighter mesh construction.

- Maintenance - Stainless steel is easier to sanitize and less absorbent than nylon, reducing bacterial growth risk.

Durability and Longevity Comparison

Stainless steel strainers offer superior durability and resistance to corrosion, making them ideal for the acidic environment of pickling. Fine-mesh nylon strainers, while effective for filtering small particles, tend to degrade faster due to exposure to vinegar and salt. Choosing stainless steel ensures long-term use without warping or material breakdown in pickling processes.

Straining Efficiency for Pickling Brines

The stainless steel strainer offers superior durability and resists corrosion, making it ideal for handling acidic pickling brines without imparting flavors. Its rigid structure ensures efficient separation of solids, maintaining clarity in the brine.

Fine-mesh nylon strainers excel at filtering smaller particles due to their tightly woven fibers, producing a smoother brine consistency. However, nylon mesh can absorb odors and degrade over time with acidic exposure, reducing long-term straining efficiency.

Impact on Flavor and Food Safety

Stainless steel strainers offer a non-reactive surface that preserves the original flavor of pickling brines, while fine-mesh nylon strainers may absorb flavors and odors, slightly altering the taste. From a food safety perspective, stainless steel is more resistant to bacteria buildup and easier to sterilize compared to nylon, which can degrade over time and harbor microbes.

- Flavor Preservation - Stainless steel maintains the purity of pickling flavors without imparting any metallic taste.

- Material Durability - Nylon strainers may retain flavors and oils, potentially affecting subsequent pickling batches.

- Food Safety - Stainless steel's smooth, non-porous surface reduces bacterial contamination risks.

Choosing stainless steel strainers enhances both flavor integrity and hygienic safety in pickling processes.

Cleaning and Maintenance Differences

Stainless steel strainers are highly durable and resistant to rust, making them easy to clean and maintain after pickling, often requiring just warm soapy water and minimal scrubbing. Fine-mesh nylon strainers, while effective for filtering small particles, tend to retain pickling residues and odors, necessitating more thorough cleaning and occasional deep soaking to prevent bacterial growth. Regular maintenance of stainless steel strainers is simpler, as they can withstand high temperatures and dishwasher cycles, unlike delicate nylon strainers which may degrade over time with repeated washing.

Heat Resistance and Performance

| Material | Stainless steel | Fine-mesh nylon |

| Heat Resistance | Withstands high temperatures without warping or melting, ideal for hot pickling brines. | Susceptible to melting or deformation at temperatures above 200degF, limiting use with boiling liquids. |

| Performance | Durable and corrosion-resistant, allows quick straining of solids while maintaining structural integrity. | Excellent for fine particles and seeds, but less durable and prone to tearing under heavy use or heat stress. |

Cost Analysis: Stainless Steel vs Nylon

Stainless steel strainers typically have a higher initial cost compared to fine-mesh nylon strainers due to the durability and longevity of the metal. Nylon strainers are more affordable upfront but may require frequent replacement because they can degrade or tear with prolonged exposure to acidic pickling solutions.

Over time, the investment in a stainless steel strainer often results in lower costs since it resists corrosion and maintains structural integrity under repeated use. Nylon strainers, while budget-friendly initially, may incur higher cumulative expenses due to their shorter lifespan and susceptibility to damage from heat and acidic environments. Evaluating the total cost of ownership favors stainless steel for sustained pickling operations where durability and reusability are essential.

Best Uses in Pickling Process

Which strainer is best suited for the pickling process, stainless steel or fine-mesh nylon? Stainless steel strainers excel in durability and resistance to acidic vinegar solutions, making them ideal for rinsing and draining pickled vegetables. Fine-mesh nylon strainers are perfect for filtering out fine particles and seeds, ensuring a clear brine during the pickling stage.

Related Important Terms

Micro-filtration capacity

Stainless steel strainers offer robust durability but have larger pores that limit their micro-filtration capacity compared to fine-mesh nylon strainers, which provide superior filtration by effectively capturing smaller particles and impurities during pickling. This enhanced micro-filtration of fine-mesh nylon strainers ensures clearer brine solutions and improved overall pickling quality.

Non-reactive pickling interface

Stainless steel strainers provide a durable, non-reactive surface ideal for pickling, preventing metallic taste or chemical reactions with acidic brines, while fine-mesh nylon strainers offer a lightweight, corrosion-resistant option that avoids metal contact but may retain odors or stains over time. Choosing a non-reactive strainer ensures consistent flavor preservation and food safety during the pickling process.

Residue retention rate

Stainless steel strainers offer a lower residue retention rate due to their rigid structure and smooth surface, allowing brine and small particles to pass through efficiently during pickling. Fine-mesh nylon strainers, with their denser weave, tend to trap more solid particles, increasing residue retention and potentially affecting the clarity of pickling liquids.

Flavor leaching control

Stainless steel strainers prevent flavor leaching during pickling by resisting corrosion and maintaining a neutral taste, ensuring the brine's original flavor remains intact. Fine-mesh nylon strainers, while effective at filtering small particles, may absorb oils and odors over time, potentially imparting unwanted flavors to the pickled product.

Brine clarity optimization

Stainless steel strainers provide superior durability and corrosion resistance for pickling, ensuring brine clarity without flavor alteration, while fine-mesh nylon strainers offer finer filtration to remove smaller particles, enhancing brine transparency though they may degrade over time. Choosing stainless steel strainers optimizes brine clarity in long-term use, whereas fine-mesh nylon strainers are ideal for delicate pickling processes requiring precise sediment control.

Particle sediment exclusion

A stainless steel strainer offers superior durability and resists staining while effectively filtering larger particles during pickling, but a fine-mesh nylon strainer excels at excluding finer sediment thanks to its tighter weave. For optimal clarity in pickling brine, a fine-mesh nylon strainer provides enhanced exclusion of small particulate matter, ensuring a cleaner final product.

Strainer pore calibration

Stainless steel strainers offer precise pore calibration with uniform holes typically ranging from 0.5 to 2 millimeters, ideal for maintaining consistent brine clarity and filtering out larger solids in pickling. Fine-mesh nylon strainers provide a tighter pore size often below 0.1 millimeters, allowing superior filtration of fine particles and sediments while resisting corrosion in acidic pickling solutions.

Nylon mesh stain resistance

Fine-mesh nylon strainers provide superior stain resistance during pickling, maintaining clarity and preventing discoloration compared to stainless steel strainers, which can develop rust or corrosion over time when exposed to acidic brines. The non-metallic nylon material also avoids metallic taste transfer, ensuring a cleaner flavor profile in pickled products.

Stainless steel enzymatic inertness

Stainless steel strainers offer superior enzymatic inertness during pickling, preventing unwanted chemical reactions that can alter flavor and texture. Unlike fine-mesh nylon strainers, stainless steel maintains durability and resists staining or odor retention, ensuring consistent, uncontaminated pickling results.

Stainless steel strainer vs Fine-mesh nylon strainer for pickling. Infographic

cookingdiff.com

cookingdiff.com