Standard lids for pickling provide a simple, airtight seal that helps preserve flavor and prevent contamination, but they may trap gases produced during fermentation. Airlock lids allow gas to escape without letting oxygen in, reducing the risk of spoilage and enabling safer fermentation. Choosing an airlock lid can improve the consistency and safety of homemade pickled products.

Table of Comparison

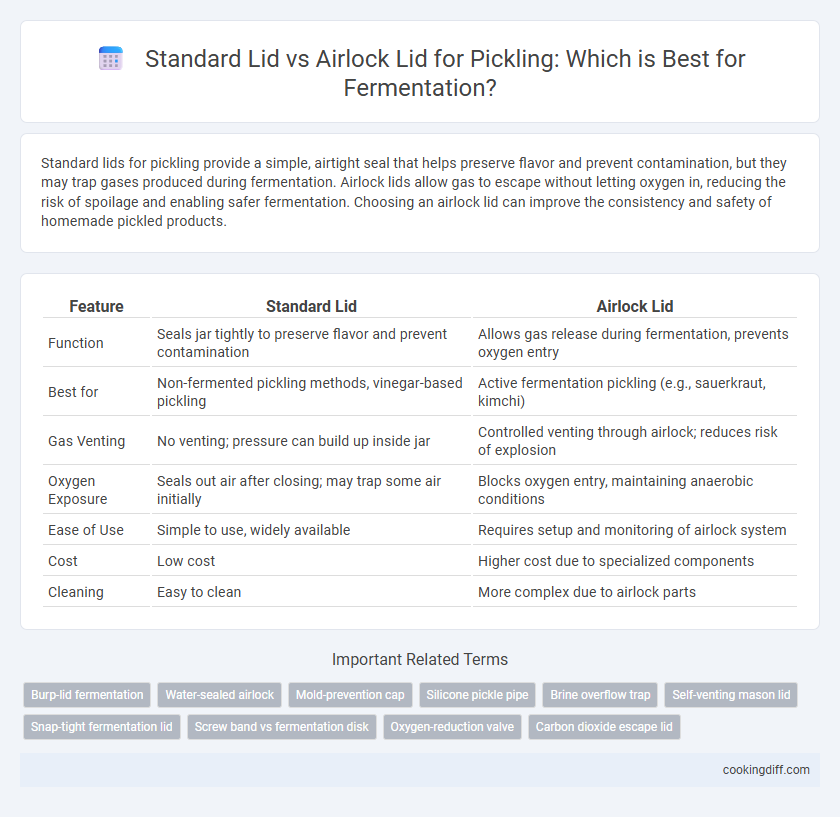

| Feature | Standard Lid | Airlock Lid |

|---|---|---|

| Function | Seals jar tightly to preserve flavor and prevent contamination | Allows gas release during fermentation, prevents oxygen entry |

| Best for | Non-fermented pickling methods, vinegar-based pickling | Active fermentation pickling (e.g., sauerkraut, kimchi) |

| Gas Venting | No venting; pressure can build up inside jar | Controlled venting through airlock; reduces risk of explosion |

| Oxygen Exposure | Seals out air after closing; may trap some air initially | Blocks oxygen entry, maintaining anaerobic conditions |

| Ease of Use | Simple to use, widely available | Requires setup and monitoring of airlock system |

| Cost | Low cost | Higher cost due to specialized components |

| Cleaning | Easy to clean | More complex due to airlock parts |

Overview of Pickling Lid Types

Standard lids for pickling jars create an airtight seal by using a two-piece design, which includes a flat metal lid and a screw band, preventing contamination during fermentation. Airlock lids feature a specialized valve or a water-filled chamber that allows gases to escape while blocking oxygen, reducing the risk of mold and ensuring optimal anaerobic conditions. Choosing between standard and airlock lids depends on the type of pickling process and desired fermentation control.

What Is a Standard Pickling Lid?

A standard pickling lid is a simple, solid metal or plastic cover used to seal jars during the pickling process. It does not allow gases to escape, which can affect fermentation but provides a tight seal for preserving flavors.

- Simple design - A standard lid consists of a flat disc that fits tightly onto a jar to prevent contamination.

- Seals airtight - It creates an airtight environment to keep pickles fresh by blocking air entry.

- Used for preservation - Suitable for non-fermented pickling methods that do not require gas release during processing.

Understanding Airlock Lids

| Airlock lids create a controlled fermentation environment by allowing gases to escape while preventing oxygen and contaminants from entering, reducing mold risk during pickling. |

| Unlike standard lids that seal jars completely and can trap gases causing pressure buildup, airlock lids maintain optimal anaerobic conditions for lactic acid bacteria to thrive. |

| Choosing an airlock lid enhances the safety and consistency of fermented pickles by preserving the natural fermentation process and preventing spoilage. |

How Standard Lids Work During Fermentation

Standard lids create a sealed environment by tightly covering the jar, preventing air from entering or escaping during fermentation. This anaerobic condition encourages beneficial bacteria to thrive while inhibiting harmful microbes.

As gases build up inside the jar, pressure increases and may cause the lid to bulge or pop, signaling active fermentation. To avoid jar breakage, it is important to periodically release the pressure by loosening the lid slightly during the process.

Airlock Lids: Features and Functionality

Airlock lids feature a built-in valve that allows gases produced during fermentation to escape while preventing oxygen and contaminants from entering the jar. This functionality helps maintain an anaerobic environment crucial for successful pickling and reduces the risk of mold growth. Their seal ensures consistent fermentation conditions, making them ideal for both beginners and experienced fermenters.

Oxygen Control: Standard vs Airlock Lids

Standard lids create a sealed environment but may trap oxygen inside jars, potentially affecting fermentation quality. Airlock lids allow gases like carbon dioxide to escape while preventing oxygen from entering, optimizing anaerobic conditions essential for proper pickling.

Oxygen control is crucial in pickling to prevent spoilage and encourage beneficial microbial activity. Airlock lids consistently maintain low oxygen levels, reducing the risk of mold growth and off-flavors common with standard lids. This controlled environment enhances fermentation efficiency and preserves pickled foods longer.

Mold and Contamination Risks Compared

Which lid type better prevents mold and contamination during pickling? Standard lids can trap moisture and oxygen, increasing the risk of mold growth and spoilage. Airlock lids allow gases to escape while keeping oxygen out, significantly reducing contamination risks and promoting safer fermentation.

Ease of Use: Standard Lid vs Airlock Lid

Standard lids for pickling jars are straightforward to use, requiring only a simple screw-on mechanism that secures the contents tightly. This simplicity makes them accessible for beginners and convenient for quick sealing.

Airlock lids incorporate a mechanism that allows gases to escape during fermentation while preventing air from entering, which can be more complex to set up. Despite the extra steps, airlock lids reduce the risk of contamination and help maintain an optimal environment for fermenting vegetables.

Flavor and Texture: Impact of Lid Choice

The choice between a standard lid and an airlock lid significantly influences the flavor and texture of pickled products. Airlock lids promote anaerobic fermentation, enhancing sourness and crispness, while standard lids may result in varied textures due to trapped gases.

- Airlock lids enable controlled fermentation - This allows beneficial bacteria to thrive, producing complex, tangy flavors and maintaining crunchiness.

- Standard lids trap gases - Gas buildup can lead to softer textures and inconsistent flavor profiles due to limited oxygen exchange.

- Airlock lids reduce spoilage risk - By preventing oxygen exposure, they help preserve desired pickling flavors and firm textures longer.

Related Important Terms

Burp-lid fermentation

Burp-lid fermentation lids allow excess gas to escape while preventing oxygen from entering, creating an ideal anaerobic environment crucial for optimal lacto-fermentation during pickling. Unlike standard lids that can trap pressure and risk jar bursting or promote mold growth, burp-lids enable consistent gas release, enhancing flavor development and ensuring safer fermentation outcomes.

Water-sealed airlock

Water-sealed airlock lids create an oxygen-free environment by allowing gases produced during fermentation to escape while preventing air and contaminants from entering, which significantly reduces the risk of mold and spoilage in pickling. Standard lids lack this venting mechanism, often requiring manual burping to release gas, increasing the chance of contamination and inconsistent fermentation results.

Mold-prevention cap

An airlock lid creates an anaerobic environment that significantly reduces mold formation during pickling by allowing gases to escape while preventing oxygen entry. Standard lids often trap moisture and oxygen, increasing the risk of mold growth and spoilage in fermented foods.

Silicone pickle pipe

Silicone pickle pipes in airlock lids provide a controlled release of gases during fermentation, reducing the risk of mold and maintaining an anaerobic environment essential for optimal pickling. Standard lids lack this specialized venting system, often leading to pressure buildup or exposure to oxygen, which can compromise the quality and safety of fermented pickles.

Brine overflow trap

Standard lids for pickling often lack a built-in brine overflow trap, increasing the risk of spills and contamination during fermentation, whereas airlock lids feature a designed brine overflow trap that effectively captures excess liquid, maintaining a clean fermentation environment. Airlock lids also allow gases to escape without letting oxygen in, promoting optimal anaerobic conditions for pickling.

Self-venting mason lid

Self-venting mason lids provide a controlled release of gases during pickling, preventing pressure buildup and reducing the risk of jar breakage compared to standard lids. These airlock lids maintain optimal anaerobic conditions essential for fermentation while minimizing contamination and spoilage.

Snap-tight fermentation lid

Snap-tight fermentation lids provide a reliable seal compared to standard lids and specialized airlock lids, preventing oxygen exposure while allowing carbon dioxide to escape during pickling. This controlled environment reduces the risk of contamination and ensures consistent fermentation, making snap-tight lids a preferred choice for home and small-scale fermenters.

Screw band vs fermentation disk

Screw bands secure the lid tightly on jars, preventing air entry during pickling, while fermentation disks under airlock lids allow gases to escape without letting oxygen in, essential for anaerobic fermentation. Choosing between a standard screw band and a fermentation disk depends on the desired fermentation control and ease of gas release during the pickling process.

Oxygen-reduction valve

An airlock lid for pickling incorporates an oxygen-reduction valve that allows carbon dioxide to escape while preventing oxygen from entering, thereby reducing oxidation and enhancing fermentation quality. Standard lids lack this valve, which can lead to oxygen exposure, increasing the risk of spoilage and less effective anaerobic fermentation.

Standard lid vs airlock lid for pickling. Infographic

cookingdiff.com

cookingdiff.com