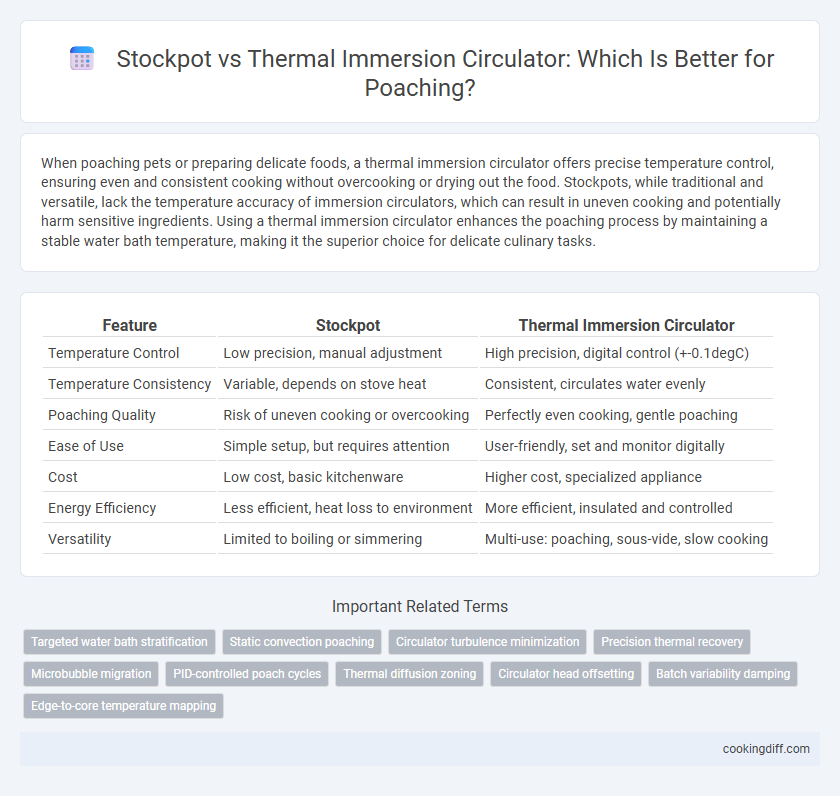

When poaching pets or preparing delicate foods, a thermal immersion circulator offers precise temperature control, ensuring even and consistent cooking without overcooking or drying out the food. Stockpots, while traditional and versatile, lack the temperature accuracy of immersion circulators, which can result in uneven cooking and potentially harm sensitive ingredients. Using a thermal immersion circulator enhances the poaching process by maintaining a stable water bath temperature, making it the superior choice for delicate culinary tasks.

Table of Comparison

| Feature | Stockpot | Thermal Immersion Circulator |

|---|---|---|

| Temperature Control | Low precision, manual adjustment | High precision, digital control (+-0.1degC) |

| Temperature Consistency | Variable, depends on stove heat | Consistent, circulates water evenly |

| Poaching Quality | Risk of uneven cooking or overcooking | Perfectly even cooking, gentle poaching |

| Ease of Use | Simple setup, but requires attention | User-friendly, set and monitor digitally |

| Cost | Low cost, basic kitchenware | Higher cost, specialized appliance |

| Energy Efficiency | Less efficient, heat loss to environment | More efficient, insulated and controlled |

| Versatility | Limited to boiling or simmering | Multi-use: poaching, sous-vide, slow cooking |

Introduction to Poaching Techniques

Poaching involves gently cooking food in liquid at low temperatures, typically between 160degF and 180degF, to preserve texture and moisture. A stockpot provides a traditional method for poaching by allowing ample liquid volume and consistent low heat maintenance.

Thermal immersion circulators offer precise temperature control for poaching, ensuring uniform cooking and preventing overcooking. This technique is favored in sous vide cooking, optimizing tenderness and flavor retention by maintaining exact poaching temperatures.

What is a Stockpot for Poaching?

What is a stockpot for poaching? A stockpot is a large, deep cooking vessel designed to hold substantial amounts of water, ideal for evenly poaching foods such as eggs, chicken, or fish. Its high capacity and even heat distribution make it a reliable choice for maintaining precise cooking temperatures during the poaching process.

Understanding Thermal Immersion Circulators

| Thermal Immersion Circulator | Maintains precise and consistent water temperature, ideal for controlled poaching of delicate foods like eggs and fish. |

| Stockpot Poaching | Traditional cooking method relying on manual temperature control, leading to potential temperature fluctuations and uneven cooking. |

| Advantages of Thermal Immersion Circulators | Provides uniform heat distribution with programmable settings, reducing the risk of overcooking and improving food texture and flavor. |

Temperature Precision: Stockpot vs Circulator

Temperature precision is crucial in poaching to achieve perfectly cooked food without overcooking. Thermal immersion circulators maintain consistent water temperatures within +-0.1degC, whereas stockpots rely on manual adjustments, leading to potential fluctuations.

- Thermal Immersion Circulator - Provides precise temperature control ensuring even and consistent poaching conditions.

- Stockpot - Temperature varies due to direct heat source and lack of regulation tools, risking uneven cooking.

- Result on Food Quality - Precise temperatures from circulators improve texture and flavor by preventing overcooking or undercooking.

Consistency in Results: Which Method Wins?

Thermal immersion circulators provide unparalleled temperature precision, ensuring consistent poaching results with minimal temperature fluctuations. Stockpots rely on manual heat control, leading to variability in cooking temperatures and less consistent outcomes.

- Temperature Accuracy - Immersion circulators maintain exact temperatures within 0.1degC for uniform cooking.

- Heat Distribution - Stockpots often have uneven heat zones, causing inconsistent doneness.

- Automation - Circulators regulate temperature automatically, reducing human error during poaching.

For consistent and repeatable poaching, thermal immersion circulators outperform traditional stockpots.

Energy Efficiency Comparison

Stockpots typically consume more energy due to longer heat retention and less precise temperature control compared to thermal immersion circulators. Thermal immersion circulators maintain consistent temperatures efficiently, minimizing energy waste during the poaching process.

- Stockpot energy consumption - Stockpots require continuous heating to maintain temperature, leading to higher overall energy usage.

- Thermal immersion circulator efficiency - Circulators use precise temperature control to reduce power output while sustaining heat, optimizing energy use.

- Energy savings potential - Thermal immersion circulators can reduce electricity consumption by up to 30% compared to stockpots during extended poaching.

Ease of Use and Convenience

Stockpots offer a straightforward setup with minimal equipment needed, making them convenient for traditional poaching methods. Thermal immersion circulators provide precise temperature control, ensuring consistent results with less monitoring, which enhances ease of use. Their compact design and programmable features add to the convenience for users seeking reliable poaching without frequent adjustments.

Versatility for Home Cooks

Stockpots offer spacious capacity, allowing home cooks to poach larger quantities or bulky items like whole fish with ease. Thermal immersion circulators provide precise temperature control, ensuring consistent poaching results for delicate foods such as eggs and seafood. The choice between these tools depends on the desired cooking precision and volume needs in a home kitchen.

Cost Considerations between Both Methods

Stockpots are generally less expensive upfront than thermal immersion circulators, making them a budget-friendly option for basic poaching needs. Thermal immersion circulators require a higher initial investment but provide precise temperature control that can justify the cost for advanced cooking techniques.

The cost of a stockpot is limited to the pot itself, often under $50, while thermal immersion circulators can range from $100 to $300 depending on features. Energy consumption is similar for both methods, but circulators achieve consistent temperatures faster, potentially saving energy over long cooking times. Investing in a thermal immersion circulator may increase cooking precision and efficiency, reducing waste and enhancing food quality in the long run.

Related Important Terms

Targeted water bath stratification

Stockpots offer limited water bath stratification, causing uneven temperature distribution during poaching and potentially inconsistent cooking results. Thermal immersion circulators provide precise temperature control by circulating water uniformly, ensuring targeted water bath stratification for consistent and optimal poaching outcomes.

Static convection poaching

Stockpots create a stable environment for static convection poaching by evenly circulating hot water around the food, maintaining consistent temperature without mechanical agitation. Thermal immersion circulators offer precise temperature control but rely on water movement, which can disrupt the gentle heat transfer characteristic of static convection poaching essential for delicate textures.

Circulator turbulence minimization

Thermal immersion circulators provide precise temperature control and create gentle water movement that minimizes turbulence, ensuring delicate foods retain their texture during poaching. Stockpots lack this controlled circulation, often resulting in uneven heat distribution and more turbulent water flow that can compromise the quality of poached items.

Precision thermal recovery

Thermal immersion circulators offer superior precision thermal recovery compared to stockpots, maintaining water temperature within +-0.1degC to ensure consistent poaching results. Stockpots rely on stovetop heat variations, causing slower recovery times and uneven temperature distribution that can compromise delicate foods.

Microbubble migration

Stockpots create uneven heat distribution, leading to inconsistent microbubble migration that can affect the delicate texture of poached foods, while thermal immersion circulators maintain precise temperature control and promote uniform microbubble formation for optimal cooking results. Consistent microbubble migration in thermal immersion circulators enhances protein coagulation and flavor infusion, ensuring superior poaching quality compared to traditional stockpots.

PID-controlled poach cycles

Stockpots provide a traditional method for poaching but often lack precise temperature control, resulting in inconsistent cooking outcomes. Thermal immersion circulators equipped with PID-controlled poach cycles maintain exact water temperatures, ensuring uniform heat distribution and optimal texture for delicate proteins.

Thermal diffusion zoning

Thermal immersion circulators provide precise thermal diffusion zoning, ensuring uniform temperature control critical for consistent poaching results, unlike stockpots which often suffer from uneven heat distribution. This targeted heat regulation prevents overcooking and preserves the delicate texture of poached foods.

Circulator head offsetting

Thermal immersion circulators with offset circulator heads ensure even water circulation and precise temperature control, reducing hotspots that can cause uneven poaching. In contrast, stockpots often lack efficient water movement, resulting in inconsistent temperatures and less reliable poached results.

Batch variability damping

Comparing stockpots to thermal immersion circulators for poaching reveals significant differences in batch variability damping, as thermal immersion circulators maintain precise, consistent temperatures that minimize fluctuations and ensure uniform cooking results. Stockpots, prone to uneven heat distribution, often lead to inconsistent poaching temperatures and increased variability across batches.

Stockpot vs thermal immersion circulator for poaching. Infographic

cookingdiff.com

cookingdiff.com