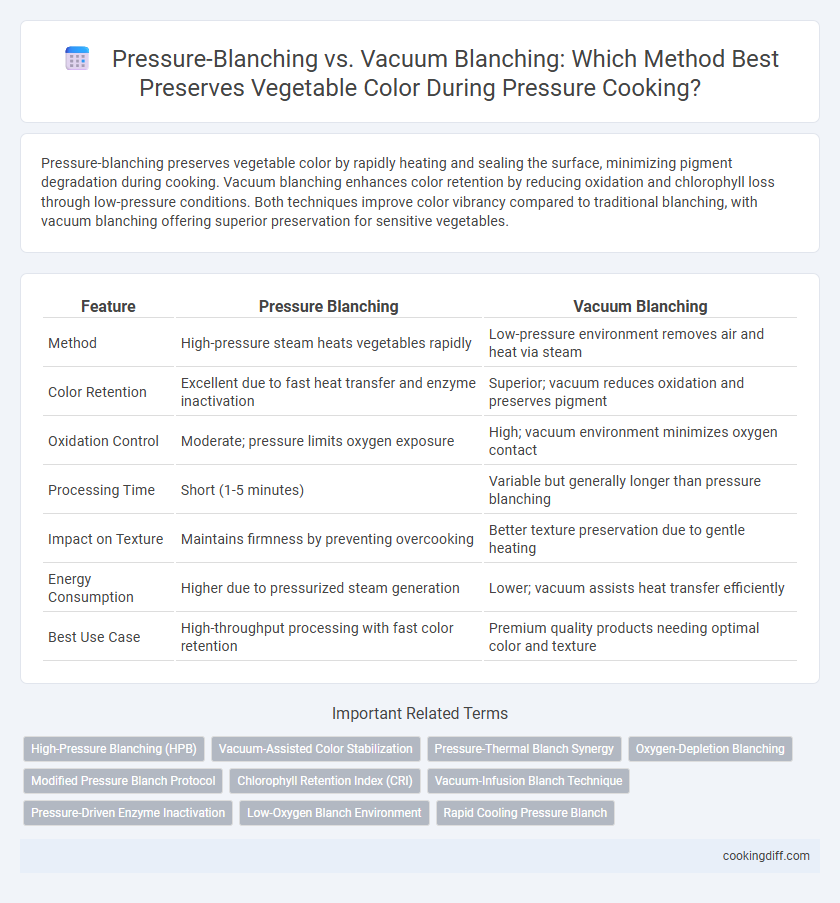

Pressure-blanching preserves vegetable color by rapidly heating and sealing the surface, minimizing pigment degradation during cooking. Vacuum blanching enhances color retention by reducing oxidation and chlorophyll loss through low-pressure conditions. Both techniques improve color vibrancy compared to traditional blanching, with vacuum blanching offering superior preservation for sensitive vegetables.

Table of Comparison

| Feature | Pressure Blanching | Vacuum Blanching |

|---|---|---|

| Method | High-pressure steam heats vegetables rapidly | Low-pressure environment removes air and heat via steam |

| Color Retention | Excellent due to fast heat transfer and enzyme inactivation | Superior; vacuum reduces oxidation and preserves pigment |

| Oxidation Control | Moderate; pressure limits oxygen exposure | High; vacuum environment minimizes oxygen contact |

| Processing Time | Short (1-5 minutes) | Variable but generally longer than pressure blanching |

| Impact on Texture | Maintains firmness by preventing overcooking | Better texture preservation due to gentle heating |

| Energy Consumption | Higher due to pressurized steam generation | Lower; vacuum assists heat transfer efficiently |

| Best Use Case | High-throughput processing with fast color retention | Premium quality products needing optimal color and texture |

Introduction to Vegetable Blanching Techniques

Pressure-blanching uses high pressure and temperature to quickly inactivate enzymes, preserving the vibrant color of vegetables more effectively than traditional methods. Vacuum blanching removes air and reduces oxidation, which helps maintain color but may be less efficient in enzyme inactivation compared to pressure-blanching. Both techniques enhance color retention, but pressure-blanching offers faster processing times and better preservation of nutritional quality in vegetables.

Understanding Pressure-Blanching: Method and Process

Pressure-blanching utilizes high pressure and temperature to rapidly inactivate enzymes in vegetables, enhancing color retention by minimizing oxidation. This method steam-cooks vegetables within a sealed environment, preserving chlorophyll and carotenoids more effectively than traditional blanching techniques.

In contrast, vacuum blanching removes oxygen, reducing enzymatic browning but operates at lower temperatures and pressures. Understanding the pressure-blanching process highlights its advantage in maintaining vibrant vegetable hues through accelerated heat transfer and enzyme deactivation.

What Is Vacuum Blanching?

Vacuum blanching is a technique that removes air and reduces pressure around vegetables to preserve their color and nutritional quality better than traditional methods. This method minimizes oxidation and enzyme activity, resulting in enhanced color retention compared to pressure-blanching.

- Vacuum Environment - Creates a low-pressure atmosphere that limits oxygen exposure, reducing discoloration.

- Temperature Control - Uses precise, lower temperatures to prevent overcooking and maintain vegetable texture.

- Enhanced Color Retention - Effectively preserves chlorophyll and carotenoids, improving appearance post-blanching.

Mechanisms of Color Degradation in Vegetables

Pressure-blanching preserves vegetable color by rapidly inactivating enzymes responsible for pigment degradation, such as polyphenol oxidase and peroxidase. Vacuum blanching reduces oxygen exposure, limiting oxidative reactions that lead to color loss and maintaining chlorophyll integrity.

- Enzymatic Degradation - Pressure-blanching rapidly deactivates enzymes that degrade pigments, preventing browning and color fading.

- Oxidative Reactions - Vacuum blanching minimizes oxygen presence, reducing oxidation of sensitive pigments like chlorophyll and carotenoids.

- Pigment Stability - Both methods aim to stabilize pigments by controlling thermal and environmental conditions during blanching.

Choosing between pressure and vacuum blanching depends on the specific color retention goals and vegetable type.

Comparative Benefits: Pressure-Blanching vs Vacuum Blanching

Pressure-blanching uses high pressure and temperature to quickly inactivate enzymes, preserving vibrant vegetable colors more effectively than traditional methods. Vacuum blanching employs reduced pressure to lower blanching temperature, minimizing color degradation while maintaining nutrient content.

- Pressure-Blanching enhances color retention - Rapid heating under pressure minimizes chlorophyll degradation and enzymatic browning in vegetables.

- Vacuum Blanching reduces thermal damage - Lower blanching temperatures under vacuum prevent pigment loss and maintain visual appeal.

- Both methods improve antioxidant preservation - Reduced exposure time and temperature help retain bioactive compounds and nutrient density in blanched vegetables.

Impact on Chlorophyll and Pigment Retention

How do pressure-blanching and vacuum blanching compare in retaining the color of vegetables? Pressure-blanching preserves chlorophyll by rapidly heating vegetables under high pressure, minimizing pigment degradation and maintaining vibrant green hues. Vacuum blanching reduces oxygen exposure, slowing chlorophyll breakdown and better preserving natural pigments in delicate vegetables prone to discoloration.

Texture and Nutrient Preservation Differences

| Blanching Method | Texture Preservation | Nutrient Retention | Color Retention |

|---|---|---|---|

| Pressure Blanching | Maintains crispness by rapidly heating, reducing enzyme activity that degrades texture. | Better preserves water-soluble vitamins like vitamin C due to shorter heating times. | Enhances color stability by quickly inactivating oxidative enzymes that cause browning. |

| Vacuum Blanching | Softens texture more gently but may lead to slight loss of firmness over time. | Preserves heat-sensitive nutrients by blanching at lower temperatures under vacuum conditions. | Effectively maintains vibrant vegetable colors by minimizing oxygen exposure during processing. |

Energy Efficiency and Processing Time Analysis

Pressure-blanching significantly reduces processing time by utilizing high-temperature steam under pressure, which accelerates heat penetration and enzyme inactivation, resulting in better color retention in vegetables. This method enhances energy efficiency by minimizing heat loss and shortening blanching duration compared to conventional methods.

Vacuum blanching operates at lower temperatures and reduced pressure, preserving vegetable color but requiring longer processing times, which may increase overall energy consumption. Energy efficiency in vacuum blanching is limited by extended operational periods despite gentler treatment conditions.

Practical Applications for Home and Industrial Cooks

Pressure-blanching utilizes high-pressure steam to preserve vibrant vegetable colors by reducing blanching time and minimizing nutrient loss, making it ideal for both home and industrial cooks seeking efficiency. Vacuum blanching, which removes air before heating, helps maintain color and texture by preventing oxidation and enzyme activity, favored in industrial settings for batch consistency. Home cooks benefit from pressure-blanchers' speed, while industrial processors prioritize vacuum blanching for large-scale, uniform color retention in vegetables.

Related Important Terms

High-Pressure Blanching (HPB)

High-Pressure Blanching (HPB) uses elevated pressure to inactivate enzymes, preserving vibrant vegetable colors more effectively than vacuum blanching by minimizing leaching and oxidation. Studies show HPB enhances chlorophyll retention and maintains nutrient integrity, resulting in superior visual and nutritional quality of blanched vegetables.

Vacuum-Assisted Color Stabilization

Vacuum blanching enhances vegetable color retention by reducing oxidation and enzymatic browning through low-oxygen environments, outperforming traditional pressure-blanching methods. This vacuum-assisted color stabilization preserves chlorophyll and carotenoids more effectively, maintaining vibrant green and orange hues in processed vegetables.

Pressure-Thermal Blanch Synergy

Pressure blanching preserves vegetable color more effectively than vacuum blanching due to its combined pressure-thermal blanch synergy, which accelerates enzyme inactivation while minimizing pigment degradation. This method enhances chlorophyll retention by maintaining cellular integrity under high pressure and temperature, resulting in higher-quality, visually appealing vegetables.

Oxygen-Depletion Blanching

Oxygen-depletion blanching, achieved through vacuum blanching, significantly enhances vegetable color retention by minimizing oxidative degradation compared to pressure blanching, which uses high temperature and steam but does not remove oxygen effectively. Studies show vacuum blanching under reduced oxygen environments preserves chlorophyll and carotenoids more efficiently, leading to brighter, more vibrant vegetable colors after processing.

Modified Pressure Blanch Protocol

Modified Pressure Blanch Protocol enhances vegetable color retention by combining controlled pressure levels with precise blanching times, outperforming traditional vacuum blanching which often leads to color leaching due to prolonged exposure to steam. This method optimizes pigment preservation, particularly chlorophyll and carotenoids, by minimizing oxidative degradation and enzyme activity during the pressure-cooking process.

Chlorophyll Retention Index (CRI)

Pressure-blanching exhibits a higher Chlorophyll Retention Index (CRI) compared to vacuum blanching, preserving the vibrant green color of vegetables more effectively by minimizing pigment degradation under controlled high-temperature steam conditions. Vacuum blanching, while beneficial for reducing oxidation, often results in lower CRI due to pressure and temperature variations that accelerate chlorophyll breakdown.

Vacuum-Infusion Blanch Technique

Vacuum-Infusion Blanch Technique enhances vegetable color retention by removing air from plant tissues, allowing blanching agents to penetrate more effectively and reduce oxidation. This method outperforms pressure-blanching by preserving chlorophyll and carotenoids, maintaining vibrant vegetable hues during processing.

Pressure-Driven Enzyme Inactivation

Pressure-blanching enhances enzyme inactivation by combining high pressure and temperature, effectively preserving the vibrant color of vegetables by reducing enzymatic browning more rapidly than vacuum blanching. Vacuum blanching primarily removes oxygen but lacks the synergistic pressure-induced enzyme denaturation that maximizes color retention during processing.

Low-Oxygen Blanch Environment

Pressure-blanching uses high pressure to rapidly heat vegetables in a low-oxygen environment, effectively preserving vibrant colors by minimizing oxidative degradation. Vacuum blanching further reduces oxygen exposure during heat treatment, enhancing color retention by limiting enzymatic browning and pigment loss in vegetables.

Pressure-blanching vs vacuum blanching for veggie color retention. Infographic

cookingdiff.com

cookingdiff.com