Inner stainless steel pots offer superior durability and resistance to scratching or chipping compared to ceramic-coated pots, making them ideal for pressure cooking pets that require frequent use. Stainless steel ensures even heat distribution and does not react with acidic pet foods, preserving flavor and nutritional value. Ceramic coated pots may provide non-stick advantages but tend to degrade faster under the high heat and pressure conditions typical in pressure cooking.

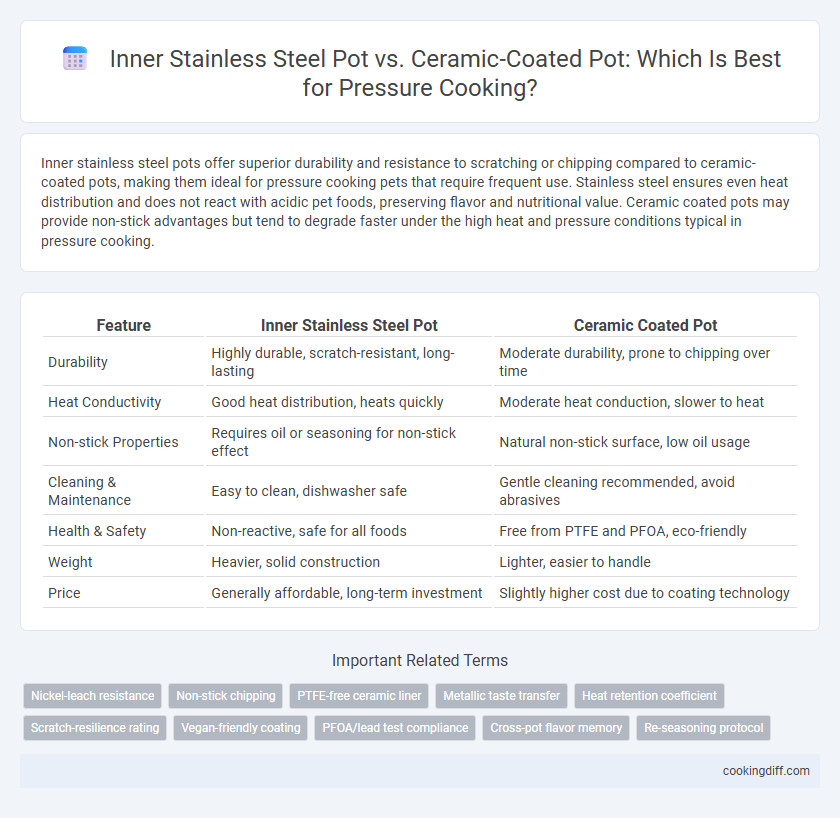

Table of Comparison

| Feature | Inner Stainless Steel Pot | Ceramic Coated Pot |

|---|---|---|

| Durability | Highly durable, scratch-resistant, long-lasting | Moderate durability, prone to chipping over time |

| Heat Conductivity | Good heat distribution, heats quickly | Moderate heat conduction, slower to heat |

| Non-stick Properties | Requires oil or seasoning for non-stick effect | Natural non-stick surface, low oil usage |

| Cleaning & Maintenance | Easy to clean, dishwasher safe | Gentle cleaning recommended, avoid abrasives |

| Health & Safety | Non-reactive, safe for all foods | Free from PTFE and PFOA, eco-friendly |

| Weight | Heavier, solid construction | Lighter, easier to handle |

| Price | Generally affordable, long-term investment | Slightly higher cost due to coating technology |

Overview: Stainless vs. Ceramic Coated Pots in Pressure Cooking

| Material | Stainless steel | Ceramic coated |

| Durability | Highly durable, resistant to scratches and dents | Less durable, prone to chipping and wear over time |

| Heat Conductivity | Moderate heat conductivity, often combined with aluminum base | Good heat distribution due to ceramic coating |

| Non-stick Properties | Does not have natural non-stick surface, requires oil or lining | Non-stick surface reduces need for oil and simplifies cleaning |

| Chemical Resistance | Resistant to acidic and alkaline foods | Generally safe but coating can degrade with harsh chemicals |

| Maintenance | Dishwasher safe and easy to clean | Hand wash recommended to preserve coating |

| Health Considerations | Non-reactive, no risk of coating leaching | Free from PTFE and PFOA but coating may chip, releasing particles |

Durability: Which Pot Lasts Longer?

Inner stainless steel pots in pressure cookers are highly durable due to their resistance to rust, scratches, and high temperatures, often lasting for many years without significant wear. Ceramic-coated pots, while non-stick and aesthetically pleasing, tend to be more prone to chipping and degrading over time, especially with heavy use or abrasive cleaning tools.

Stainless steel pots maintain their structural integrity and performance longer, making them a preferred choice for frequent pressure-cooking. Ceramic coatings may require more careful handling to preserve their lifespan, resulting in potentially shorter durability compared to stainless steel options.

Heat Conductivity and Cooking Performance

The inner stainless steel pot offers superior heat conductivity, ensuring even heat distribution and consistent cooking performance under pressure. Stainless steel's durability also allows it to withstand high temperatures without warping or degrading, making it ideal for frequent pressure-cooking.

Ceramic-coated pots provide a non-stick surface that eases food release but generally have lower heat conductivity compared to stainless steel, potentially leading to uneven cooking. The ceramic coating may wear over time, affecting long-term cooking efficiency and heat retention during pressure-cooking.

Safety Considerations: Toxins and Reactions

Inner stainless steel pots for pressure cooking are highly resistant to chemical reactions and do not leach harmful substances, ensuring food safety under high pressure and temperature. Ceramic-coated pots can offer non-stick properties but may degrade over time, potentially releasing toxins if the coating is scratched or damaged.

- Stainless steel durability - Stainless steel inner pots resist corrosion and do not react with acidic or alkaline foods, maintaining food purity.

- Ceramic coating risks - Ceramic-coated pots may chip or wear down with frequent use, posing a risk of toxin release from damaged layers.

- Safety in high heat - Stainless steel withstands high heat without altering its surface, making it safer for pressure cooking than compromised ceramic coatings.

Ease of Cleaning and Maintenance

Inner stainless steel pots for pressure cooking offer superior durability and resist staining and odor retention, making them easier to clean with simple washing or dishwasher use. Ceramic coated pots require gentler cleaning to preserve their non-stick surfaces, often needing non-abrasive sponges and mild detergents to prevent scratching. Over time, stainless steel maintains its ease of maintenance without the risk of coating degradation, ensuring long-term usability for pressure cooking tasks.

Scratch and Stain Resistance Comparison

Inner stainless steel pots exhibit superior scratch resistance compared to ceramic coated pots, maintaining a smooth cooking surface over extended use. Ceramic coated pots, while visually appealing, are more susceptible to scratches and staining, which can affect their durability and performance in pressure cooking.

- Scratch Resistance - Stainless steel withstands abrasive utensils and cleaning better than ceramic coatings, preventing surface damage.

- Stain Resistance - Stainless steel resists discoloration from acidic and oily foods more effectively than ceramic coatings.

- Longevity - The durable nature of stainless steel enhances the lifespan of pressure cooker inner pots compared to ceramic coated alternatives.

Food Flavor Preservation and Odor Retention

Which inner pot material better preserves food flavor and prevents odor retention in pressure cooking? Inner stainless steel pots are non-porous, resisting odor absorption and maintaining pure flavors across diverse recipes. Ceramic coated pots can retain some flavors and odors over time due to microscopic surface porosities, potentially affecting the taste of subsequent meals.

Compatibility with Pressure Cooker Models

Inner stainless steel pots boast broad compatibility with most pressure cooker models due to their durability and ability to withstand high pressure. Ceramic coated pots may have limited compatibility, often designed for specific pressure cookers with gentle heat requirements.

- Stainless steel pots support universal fit - Their robust construction allows use in electric and stovetop pressure cookers alike.

- Ceramic coated pots suit select models - These are typically compatible with electric pressure cookers that feature non-metallic inner pot requirements.

- Durability influences compatibility - Stainless steel endures frequent pressure cycles better than ceramic coatings do, expanding its compatibility range.

Choosing the right inner pot ensures optimal pressure cooking performance and longevity across various pressure cooker brands and types.

Price and Value for Money

Inner stainless steel pots for pressure cookers generally come at a higher initial cost but offer superior durability and resistance to corrosion, making them a long-term investment with excellent value for money. Ceramic coated pots are often more affordable upfront and provide non-stick convenience, but they tend to wear out faster and may require replacement sooner, impacting overall cost-effectiveness. Choosing between the two depends on budget priorities and how frequently the pressure cooker is used, with stainless steel delivering better value over extended use.

Related Important Terms

Nickel-leach resistance

Inner stainless steel pots offer superior nickel-leach resistance compared to ceramic-coated pots, making them safer for individuals with nickel allergies during pressure-cooking. Ceramic-coated pots may degrade over time under high-pressure heat, potentially increasing the risk of nickel exposure.

Non-stick chipping

Inner stainless steel pots for pressure cookers offer superior durability and resist non-stick coating chipping, ensuring long-lasting performance without peeling or flaking. Ceramic-coated pots, while providing excellent non-stick properties initially, are more prone to chipping and degradation over time, especially under high pressure and frequent use.

PTFE-free ceramic liner

Inner stainless steel pots in pressure cookers offer durability, non-reactivity, and ease of cleaning, whereas ceramic-coated pots provide a PTFE-free, non-toxic cooking surface that resists scratching and chemical leaching. The PTFE-free ceramic liner is especially valued for health-conscious users seeking a safe, eco-friendly alternative without compromising heat distribution or cooking performance.

Metallic taste transfer

Inner stainless steel pots in pressure cookers are highly resistant to metallic taste transfer, maintaining the food's pure flavor profile due to their non-reactive surface. Ceramic-coated pots may impart slight flavor changes over time as the coating can degrade or react with acidic ingredients, potentially causing subtle metallic aftertastes.

Heat retention coefficient

Inner stainless steel pots in pressure cookers have a higher heat retention coefficient due to their dense metal composition, enabling more efficient and consistent heat distribution during cooking. Ceramic coated pots, while offering non-stick benefits, generally have lower heat retention, which can result in slower temperature recovery and less energy efficiency under high-pressure conditions.

Scratch-resilience rating

Inner stainless steel pots for pressure cookers offer superior scratch resistance due to their durable, non-porous surface that withstands abrasive utensils and frequent use without degrading. Ceramic-coated pots, while providing a non-stick surface, typically have lower scratch-resilience and are more prone to chipping or wearing down over time with aggressive use.

Vegan-friendly coating

Inner stainless steel pots provide a durable, non-reactive surface that ensures no leaching of harmful chemicals, making them ideal for vegan-friendly pressure cooking. Ceramic coated pots offer a chemical-free, non-stick alternative but may wear over time, requiring careful maintenance to retain their vegan-safe coating integrity.

PFOA/lead test compliance

Inner stainless steel pots for pressure cooking consistently pass PFOA and lead compliance tests, offering a non-reactive and durable cooking surface free from harmful chemicals. Ceramic coated pots may vary in quality, with some products failing PFOA and lead safety standards, making stainless steel a safer choice for health-conscious consumers.

Cross-pot flavor memory

Inner stainless steel pots for pressure cooking resist cross-pot flavor memory due to their non-porous, durable surface that does not absorb food odors or flavors. Ceramic coated pots, while providing non-stick benefits, are more prone to retaining flavors over time because their porous surface allows subtle absorption, impacting the purity of subsequent dishes.

Inner stainless pot vs Ceramic coated pot for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com