Traditional pressure sealing relies on creating a completely airtight environment to build steam pressure, speeding up cooking times and retaining moisture. Air fryer pressure crisping combines pressure cooking with hot air circulation to achieve both tender interiors and crispy exteriors. This innovative method enhances texture while preserving the efficiency of conventional pressure cooking.

Table of Comparison

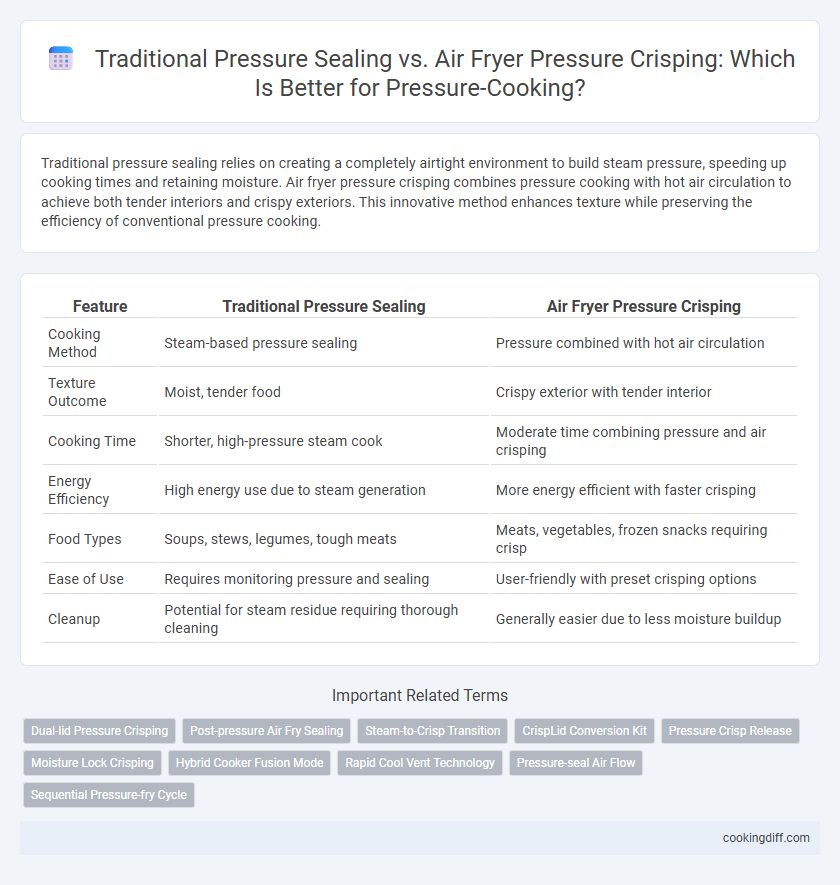

| Feature | Traditional Pressure Sealing | Air Fryer Pressure Crisping |

|---|---|---|

| Cooking Method | Steam-based pressure sealing | Pressure combined with hot air circulation |

| Texture Outcome | Moist, tender food | Crispy exterior with tender interior |

| Cooking Time | Shorter, high-pressure steam cook | Moderate time combining pressure and air crisping |

| Energy Efficiency | High energy use due to steam generation | More energy efficient with faster crisping |

| Food Types | Soups, stews, legumes, tough meats | Meats, vegetables, frozen snacks requiring crisp |

| Ease of Use | Requires monitoring pressure and sealing | User-friendly with preset crisping options |

| Cleanup | Potential for steam residue requiring thorough cleaning | Generally easier due to less moisture buildup |

Introduction to Pressure Cooking Technologies

Traditional pressure sealing relies on steam pressure to cook food quickly by trapping moisture inside a sealed pot, which enhances flavor and texture. Air fryer pressure crisping combines high-pressure steam with circulating hot air to achieve a crispy exterior while maintaining tender interiors. This hybrid technology revolutionizes pressure cooking by delivering faster cooking times and improved food texture compared to conventional methods.

What is Traditional Pressure Sealing?

Traditional pressure sealing involves locking moisture and steam inside a sealed cooking vessel to rapidly raise temperature and cook food under high pressure. This method relies on steam pressure to tenderize ingredients and reduce cooking time efficiently.

- Moisture retention - Seals in steam to create a high-pressure environment that accelerates cooking.

- Temperature control - Maintains consistent heat by preventing steam escape, enabling uniform cooking.

- Flavor enhancement - Locks in natural juices and flavors by minimizing evaporation during the cooking process.

Overview of Air Fryer Pressure Crisping

How does air fryer pressure crisping improve the pressure-cooking process compared to traditional pressure sealing? Air fryer pressure crisping combines high-pressure steam cooking with rapid air circulation to achieve a crispy exterior and tender interior. This method enhances texture and flavor while reducing cooking time, unlike traditional pressure sealing that primarily focuses on moisture retention without crisping.

Key Differences Between Pressure Sealing and Pressure Crisping

Traditional pressure sealing uses steam and high pressure to cook food quickly, maintaining moisture and tenderness. Air fryer pressure crisping combines pressure cooking with hot air circulation, creating a crispy exterior while preserving juiciness inside. The key difference lies in texture: pressure sealing focuses on moisture retention, whereas pressure crisping enhances crispiness without added oil.

Cooking Time and Efficiency Comparison

| Method | Cooking Time | Efficiency |

|---|---|---|

| Traditional Pressure Sealing | Typically requires 15-30 minutes depending on food type. | Relies on steam pressure, which speeds up cooking by up to 70% compared to conventional methods but can retain moisture, sometimes requiring longer post-cook browning. |

| Air Fryer Pressure Crisping | Combines pressure cooking with rapid hot air circulation for a total of 10-20 minutes. | Increases cooking efficiency by crisping food faster and reducing overall preparation time by approximately 25%, while delivering a crunchy texture without additional oil. |

Texture and Flavor Outcomes

Traditional pressure sealing produces tender, moist textures by trapping steam and maintaining high moisture levels during cooking. Air fryer pressure crisping enhances texture by combining pressure cooking with rapid air circulation, resulting in a crispy exterior and intensified flavors.

- Moisture Retention - Traditional pressure sealing locks in steam, preserving juiciness and softness in foods.

- Crisp Texture - Air fryer pressure crisping creates a golden, crunchy crust that traditional methods cannot achieve.

- Flavor Development - The rapid air flow in air fryer systems promotes Maillard browning, enriching taste complexity.

The innovative air fryer pressure crisping technique offers a superior balance of tenderness and crispness, enhancing both texture and flavor in pressure-cooked meals.

Nutritional Impacts of Each Method

Traditional pressure sealing cooks food by trapping steam, preserving nutrients like vitamins and minerals more effectively than boiling methods, but can sometimes lead to slight nutrient degradation due to high heat and steam exposure. Air fryer pressure crisping uses rapid air circulation combined with pressure, which tends to reduce fat content and retains texture while maintaining higher levels of certain antioxidants compared to traditional methods.

- Traditional pressure sealing retains water-soluble vitamins - The steam environment minimizes nutrient loss compared to open boiling.

- Air fryer pressure crisping lowers fat content - Rapid air circulation allows for crisp textures with less added fat.

- Air fryer method preserves antioxidants better - Shorter cooking times and controlled temperature reduce oxidation of sensitive compounds.

Equipment Maintenance and Durability

Traditional pressure cookers feature simple sealing rings and metal locks that require regular inspection and replacement to maintain airtight performance, ensuring long-term durability. Their straightforward design allows for easy maintenance but can suffer from wear due to constant pressure and heat exposure.

Air fryer pressure crisping systems incorporate advanced silicone gaskets and electronic locking mechanisms, demanding more specialized maintenance but offering enhanced sealing precision. These components typically enhance equipment lifespan by reducing the risk of leaks and wear compared to conventional pressure cookers.

Cost and Space Considerations

Traditional pressure cookers are generally more affordable and compact, making them suitable for small kitchens and budget-conscious users. They require less storage space due to their simpler design and multifunctionality.

Air fryer pressure crispers combine pressure cooking with air frying, resulting in a higher upfront cost and larger footprint. These appliances often demand more counter space and may not fit well in smaller kitchens. However, their versatility can reduce the need for multiple kitchen gadgets, potentially offsetting space concerns for some users.

Related Important Terms

Dual-lid Pressure Crisping

Dual-lid pressure crisping combines traditional pressure sealing with advanced air fryer technology, creating a sealed environment that locks in moisture while applying hot air circulation for a crispy finish. This method enhances flavor and texture by pressure-cooking food quickly and then crisping it without excess oil, unlike conventional pressure sealing that lacks the ability to achieve a crispy exterior.

Post-pressure Air Fry Sealing

Post-pressure air fry sealing combines the intense steam heat of traditional pressure cooking with rapid hot air circulation to create a crisp, golden exterior without moisture loss. Unlike conventional sealing methods, air fryer pressure crisping locks in juices while delivering a texture similar to frying, enhancing flavor and reducing cooking time.

Steam-to-Crisp Transition

Traditional pressure sealing relies on high-pressure steam to cook food quickly but often results in a moist, soft texture due to trapped condensation. Air fryer pressure crisping incorporates hot air circulation after pressure cooking, enabling a steam-to-crisp transition that creates a crispy exterior while maintaining tender, juicy interior.

CrispLid Conversion Kit

The CrispLid Conversion Kit transforms traditional pressure sealing methods by enabling air fryer pressure crisping within pressure cookers, enhancing browning and texture without sacrificing moisture retention. This innovative lid attachment integrates air frying technology directly into pressure cooking, delivering crispy, evenly cooked results faster than conventional pressure sealing techniques.

Pressure Crisp Release

Pressure crisp release in air fryer pressure cooking uses precise temperature and airflow control to quickly reduce internal pressure while achieving a crispy exterior, unlike traditional pressure sealing that relies on gradual steam venting. This innovative method enhances texture and flavor by balancing rapid pressure release with optimal heat distribution, minimizing moisture retention often found in conventional pressure cooking.

Moisture Lock Crisping

Traditional pressure sealing traps steam to cook food quickly while retaining moisture, but often results in softer textures. Air fryer pressure crisping combines high-pressure cooking with circulating hot air to lock in moisture while creating a crispy, golden exterior.

Hybrid Cooker Fusion Mode

Hybrid Cooker Fusion Mode combines traditional pressure sealing with Air fryer pressure crisping to deliver fast cooking times while preserving food texture and flavor. This technology uses sealed high-pressure steam for tenderizing, followed by intense dry heat circulation to achieve a crispy, golden finish.

Rapid Cool Vent Technology

Rapid Cool Vent Technology drastically reduces cooling time in pressure-cooking by quickly releasing steam, enhancing safety and efficiency compared to traditional pressure sealing methods that rely on gradual pressure drop. Unlike traditional pressure sealing, air fryer pressure crisping integrates Rapid Cool Vent Technology to maintain optimal cooking pressure while achieving a crispy texture through controlled rapid cooling and steam release.

Pressure-seal Air Flow

Traditional pressure sealing relies on creating a tight, steam-trapped environment to cook food quickly under high pressure, while air fryer pressure crisping uses a combination of pressurized steam and high-velocity air circulation to achieve a crisp texture. The pressure-seal air flow in air fryer pressure crisping enhances heat transfer and moisture reduction, resulting in faster cooking times and improved surface crispiness compared to conventional pressure cookers.

Traditional pressure sealing vs Air fryer pressure crisping for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com