Conventional pressure cookers require manual monitoring and release of steam, demanding close attention to prevent overcooking or accidents. Instant pressure cookers offer programmable settings and automatic pressure control, making pressure-cooking more convenient and safer. Both types efficiently tenderize pet food, but instant models provide greater precision and time-saving benefits.

Table of Comparison

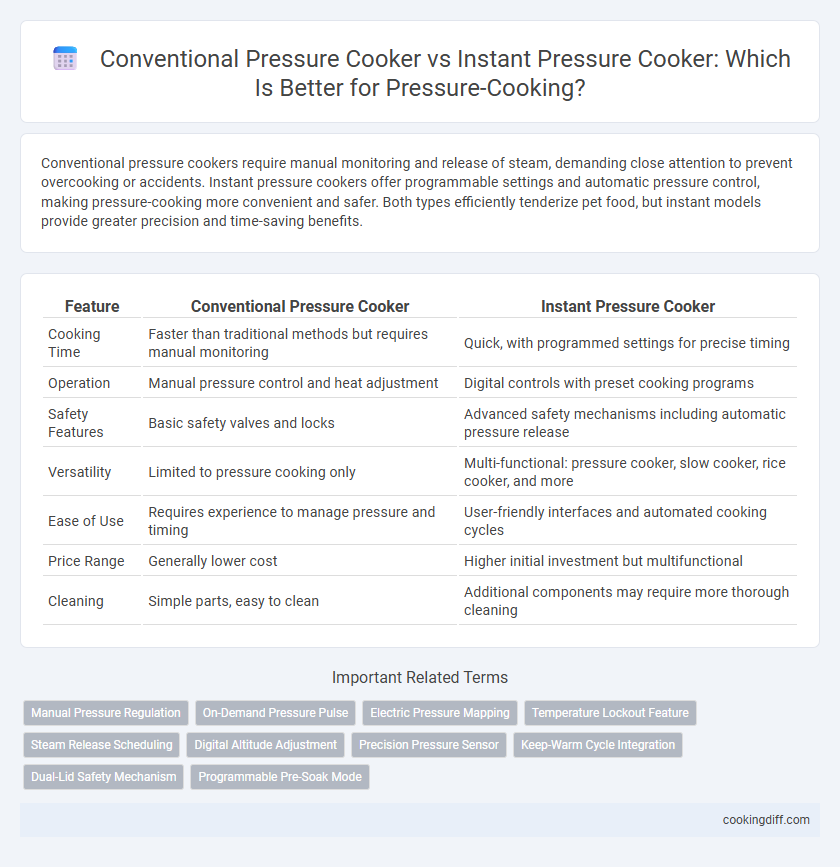

| Feature | Conventional Pressure Cooker | Instant Pressure Cooker |

|---|---|---|

| Cooking Time | Faster than traditional methods but requires manual monitoring | Quick, with programmed settings for precise timing |

| Operation | Manual pressure control and heat adjustment | Digital controls with preset cooking programs |

| Safety Features | Basic safety valves and locks | Advanced safety mechanisms including automatic pressure release |

| Versatility | Limited to pressure cooking only | Multi-functional: pressure cooker, slow cooker, rice cooker, and more |

| Ease of Use | Requires experience to manage pressure and timing | User-friendly interfaces and automated cooking cycles |

| Price Range | Generally lower cost | Higher initial investment but multifunctional |

| Cleaning | Simple parts, easy to clean | Additional components may require more thorough cleaning |

Introduction to Pressure Cooking: Conventional vs. Instant Pressure Cookers

Conventional pressure cookers use a stovetop heat source to build pressure, requiring manual monitoring and adjustment of heat levels. Instant pressure cookers, often electric, feature programmable settings and automatic pressure control for convenience and precision. Both types reduce cooking time significantly by raising the boiling point of water, but instant pressure cookers offer enhanced safety and versatility.

How Conventional Pressure Cookers Work

Conventional pressure cookers cook food by trapping steam under a sealed lid, building pressure to raise the boiling point of water and cook food faster. They rely on manual heat control and often require monitoring to maintain appropriate pressure levels.

- Steam Pressure Creation - Steam forms from boiling water, increasing pressure inside the sealed pot to cook food efficiently.

- Manual Temperature Regulation - Users adjust stove heat to maintain pressure, requiring attention during cooking.

- Simple Mechanical Design - Conventional cookers use a weighted valve or spring mechanism to regulate pressure and release steam.

How Instant Pressure Cookers Operate

How do instant pressure cookers operate differently from conventional pressure cookers? Instant pressure cookers use computerized microprocessors to precisely control cooking temperature and pressure levels, ensuring consistent results. Conventional pressure cookers rely on manual adjustments and a weighted valve system to regulate pressure, which requires more user attention and experience.

Cooking Performance Comparison

Conventional pressure cookers provide consistent high-pressure cooking, ideal for slow-cooking tough meats and stews, but require manual monitoring and timing adjustments. Instant pressure cookers offer precise digital controls with multiple cooking modes, resulting in faster cooking times and greater versatility. Both types maintain optimal pressure levels for efficient heat transfer, but instant pressure cookers enhance convenience with automated safety features and preset programs.

Safety Features: Conventional vs. Instant Models

Conventional pressure cookers rely on basic safety mechanisms such as pressure release valves and locking lids to prevent accidents. These models require manual monitoring to maintain safe cooking pressure levels.

Instant pressure cookers incorporate advanced safety features including multiple pressure sensors, automatic pressure control, and fail-safe locking systems. These digital models reduce the risk of user error by regulating pressure and temperature precisely. Enhanced seals and overpressure protection ensure safer operation compared to traditional cookers.

Ease of Use and Convenience

Instant pressure cookers offer superior ease of use with programmable settings and digital controls that simplify the cooking process. Conventional pressure cookers rely on manual pressure monitoring, requiring more attention and experience to operate safely and effectively.

- Programmable Controls - Instant pressure cookers feature presets for various recipes, reducing guesswork and cooking time.

- Manual Operation - Conventional cookers require users to manually adjust heat and monitor pressure levels.

- Safety Mechanisms - Instant cookers include built-in safety features that automatically regulate pressure and temperature.

Instant pressure cookers provide a more convenient and user-friendly experience, making pressure-cooking accessible to all skill levels.

Versatility and Pre-set Functions

Conventional pressure cookers offer straightforward functionality with manual control over cooking time and pressure, providing reliable results but limited versatility. They require constant monitoring to adjust heat and prevent overcooking, lacking pre-set programs.

Instant pressure cookers feature multiple pre-set cooking functions tailored for specific dishes like rice, meat, and desserts, enhancing versatility and ease of use. Digital controls and timers automate the cooking process, reducing the need for user intervention and increasing consistency.

Energy Efficiency and Cooking Time

| Pressure Cooker Type | Energy Efficiency | Cooking Time |

|---|---|---|

| Conventional Pressure Cooker | Uses more energy due to longer heat-up and pressure release phases, resulting in higher fuel consumption. | Typically takes 10-15 minutes longer as it relies on stovetop temperature control and slower pressure build-up. |

| Instant Pressure Cooker | More energy-efficient by maintaining precise pressure levels electronically, reducing energy waste. | Cooks meals 20-30% faster with automated pressure and temperature adjustments. |

Maintenance and Durability

Conventional pressure cookers are typically constructed with thicker stainless steel or aluminum, offering robust durability and resistance to wear over time. Maintenance is straightforward, involving regular gasket and valve checks to ensure proper sealing and safety.

Instant pressure cookers incorporate electronic components and multiple safety features, requiring more careful cleaning and occasional software updates to maintain optimal performance. Their advanced design offers convenience but may have a shorter lifespan compared to traditional models due to electronic part sensitivity.

Related Important Terms

Manual Pressure Regulation

Conventional pressure cookers require manual pressure regulation by adjusting the heat source and monitoring the pressure release valve to maintain the desired cooking pressure. Instant pressure cookers feature automated pressure control systems that precisely regulate internal pressure and cooking time, eliminating the need for manual adjustments.

On-Demand Pressure Pulse

Conventional pressure cookers rely on a steady build-up of steam pressure to cook food, while instant pressure cookers use On-Demand Pressure Pulse technology to rapidly adjust pressure levels for precise, efficient cooking. This pulse mechanism enhances flavor infusion and texture consistency by dynamically controlling pressure cycles throughout the cooking process.

Electric Pressure Mapping

Electric pressure cookers offer precise pressure mapping through integrated sensors that continuously monitor temperature and pressure, ensuring consistent cooking conditions compared to conventional stovetop pressure cookers. Conventional pressure cookers rely on manual adjustments and pressure indicators, resulting in less accurate pressure control and variable cooking outcomes.

Temperature Lockout Feature

Conventional pressure cookers rely on manual pressure regulation without a temperature lockout feature, which can lead to overheating or undercooking if not closely monitored. Instant pressure cookers incorporate an advanced temperature lockout system that maintains optimal cooking temperature, ensuring consistent pressure and enhanced safety throughout the cooking process.

Steam Release Scheduling

Conventional pressure cookers typically feature a manual steam release valve that requires constant attention to regulate pressure and release steam gradually, enhancing safety and control in cooking. Instant pressure cookers offer automated steam release scheduling with programmable settings, enabling precise management of pressure cycles for consistent cooking results and convenience.

Digital Altitude Adjustment

Conventional pressure cookers rely on manual pressure control using weighted valves or dial settings, which limits precise altitude adjustments and can affect cooking times and safety at different elevations. Instant pressure cookers feature digital altitude adjustment capabilities, automatically calibrating pressure levels to ensure consistent cooking performance and optimal safety regardless of elevation changes.

Precision Pressure Sensor

Conventional pressure cookers rely on simple weighted valves to regulate pressure, leading to less precise pressure control and potential overcooking. Instant pressure cookers utilize advanced precision pressure sensors that continuously monitor and adjust internal pressure for consistent and accurate cooking results.

Keep-Warm Cycle Integration

Conventional pressure cookers lack automatic Keep-Warm cycle integration, requiring manual timing and monitoring to prevent food overcooking. Instant pressure cookers feature built-in Keep-Warm functions that maintain optimal serving temperature for extended periods without additional supervision.

Dual-Lid Safety Mechanism

Conventional pressure cookers typically feature a single lid safety lock, while Instant pressure cookers incorporate a dual-lid safety mechanism that enhances user protection by preventing lid removal under high pressure. This advanced design in Instant pressure cookers reduces the risk of accidents, ensuring safer pressure-cooking experiences.

Conventional pressure cooker vs instant pressure cooker for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com