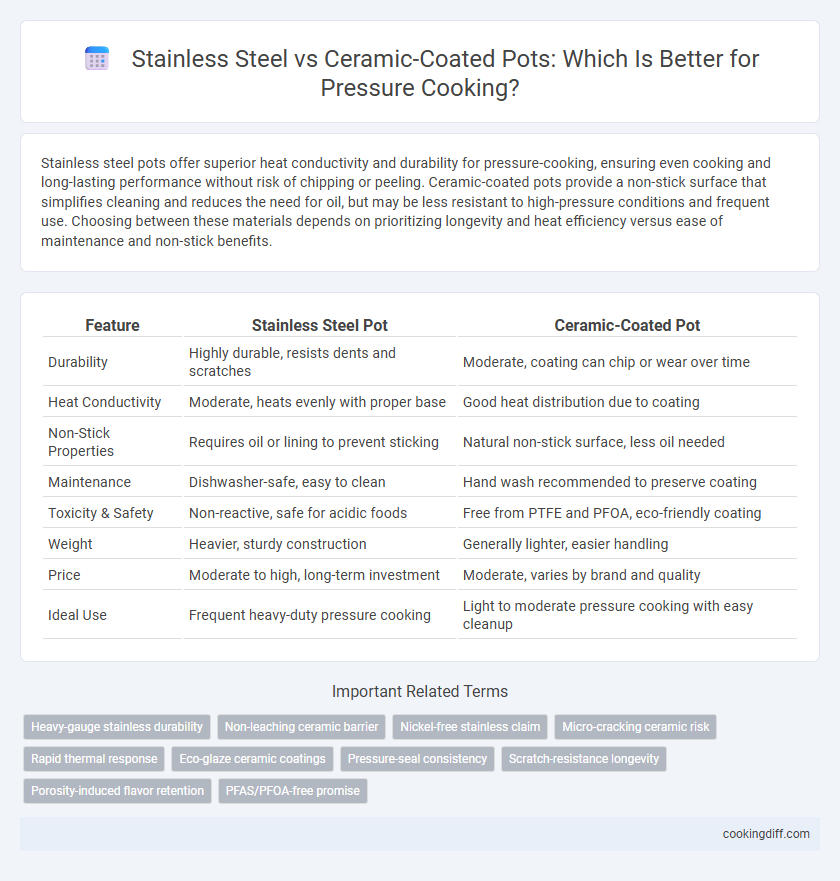

Stainless steel pots offer superior heat conductivity and durability for pressure-cooking, ensuring even cooking and long-lasting performance without risk of chipping or peeling. Ceramic-coated pots provide a non-stick surface that simplifies cleaning and reduces the need for oil, but may be less resistant to high-pressure conditions and frequent use. Choosing between these materials depends on prioritizing longevity and heat efficiency versus ease of maintenance and non-stick benefits.

Table of Comparison

| Feature | Stainless Steel Pot | Ceramic-Coated Pot |

|---|---|---|

| Durability | Highly durable, resists dents and scratches | Moderate, coating can chip or wear over time |

| Heat Conductivity | Moderate, heats evenly with proper base | Good heat distribution due to coating |

| Non-Stick Properties | Requires oil or lining to prevent sticking | Natural non-stick surface, less oil needed |

| Maintenance | Dishwasher-safe, easy to clean | Hand wash recommended to preserve coating |

| Toxicity & Safety | Non-reactive, safe for acidic foods | Free from PTFE and PFOA, eco-friendly coating |

| Weight | Heavier, sturdy construction | Generally lighter, easier handling |

| Price | Moderate to high, long-term investment | Moderate, varies by brand and quality |

| Ideal Use | Frequent heavy-duty pressure cooking | Light to moderate pressure cooking with easy cleanup |

Overview: Stainless Steel vs Ceramic-Coated Pots for Pressure Cooking

Stainless steel pots offer superior durability and resistance to high pressure, making them ideal for pressure cooking due to their non-reactive surface and excellent heat distribution. Ceramic-coated pots provide a non-stick surface that reduces food sticking and is easier to clean, but they may be less durable under constant high pressure and frequent use. Choosing between stainless steel and ceramic-coated pots depends on prioritizing long-term resilience versus ease of maintenance during pressure cooking.

Material Composition and Durability

Stainless steel pots for pressure cooking are made from layered alloys, providing exceptional strength and resistance to warping under high pressure. Ceramic-coated pots feature an aluminum base with a non-metallic ceramic surface, offering good heat distribution but lower durability due to coating wear.

- Material Composition - Stainless steel pots consist of durable metal alloys that withstand high temperatures and pressure without degrading.

- Ceramic-Coated Surface - Ceramic coatings provide a non-stick, chemically inert surface but are prone to chipping and scratches over time.

- Durability - Stainless steel's robust construction ensures long-lasting use, while ceramic coatings require careful handling to maintain integrity.

Heat Conductivity and Distribution

Stainless steel pots for pressure cooking offer moderate heat conductivity, ensuring even and consistent heat distribution across the base, which helps prevent hot spots and uneven cooking. Their durability and resistance to warping maintain efficient heat transfer over prolonged use.

Ceramic-coated pressure cooker pots provide superior heat retention and more uniform heat distribution due to the ceramic layer's excellent thermal properties. However, they may heat up slower initially and require careful handling to avoid damaging the coating, which can affect heat conduction over time.

Safety Features and Toxicity Concerns

Stainless steel pots for pressure cooking are renowned for their non-reactive surfaces, eliminating risks of leaching harmful chemicals into food even under high pressure and heat. Their durable construction ensures resistance to scratching and corrosion, enhancing long-term safety during intense cooking processes.

Ceramic-coated pots offer a non-toxic alternative with coatings free from PTFE and PFOA, reducing concerns about toxic fumes when overheated. However, the ceramic layer can chip or wear over time, potentially exposing the underlying metal and affecting safety if not properly maintained.

Ease of Cleaning and Maintenance

Which pressure-cooking pot is easier to clean and maintain, stainless steel or ceramic-coated? Stainless steel pressure cookers are highly durable and resistant to stains, making them easier to scrub and maintain over time without worrying about surface damage. Ceramic-coated pots require gentle cleaning to preserve the non-stick layer but offer quick cleanup due to food's reduced sticking, though careful handling is essential to avoid chipping.

Compatibility with Pressure Cookers

Stainless steel pots offer excellent compatibility with most pressure cookers due to their durability and ability to withstand high pressure and temperature. Ceramic-coated pots may have limitations with certain pressure cooker models, as their coating can be sensitive to extreme heat and pressure changes.

- Durability - Stainless steel resists warping and corrosion under pressure cooker conditions, ensuring long-term use.

- Heat Resistance - Ceramic coatings can degrade or chip when exposed to the intense heat and pressure found inside many pressure cookers.

- Compatibility - Stainless steel pots are widely compatible with electric and stovetop pressure cookers, while ceramic-coated pots require careful manufacturer guidelines.

Flavor Preservation and Food Reactivity

Stainless steel pots excel in flavor preservation due to their non-reactive surface, ensuring no metallic taste seeps into acidic or aromatic ingredients during pressure cooking. Ceramic-coated pots offer a non-stick surface but may react with highly acidic foods, potentially altering the flavor profile over time. For consistent flavor integrity and minimal food reactivity, stainless steel is the preferred choice in pressure-cooking applications.

Cost Comparison: Investment and Longevity

| Pot Type | Initial Investment | Longevity |

|---|---|---|

| Stainless Steel Pot | Higher upfront cost, typically $70-$150 | Durable with a lifespan over 10 years, highly resistant to rust and corrosion |

| Ceramic-Coated Pot | Lower initial price, usually $40-$90 | Coating may degrade within 3-5 years, requiring replacement sooner |

User Experience: Weight and Handling

Stainless steel pots tend to be heavier, offering a sturdy feel but requiring more effort to handle during pressure cooking. Ceramic-coated pots are lighter, making them easier to maneuver but sometimes less robust in overall durability.

- Weight difference - Stainless steel pots typically weigh 20-30% more than ceramic-coated ones, impacting ease of lifting.

- Handling comfort - Ceramic-coated pots often feature ergonomic handles that enhance grip and reduce strain.

- Balance - The heavier stainless steel base provides stability on induction cooktops, improving user confidence.

Choosing between weight and ease of handling depends on individual strength and cooking habits.

Related Important Terms

Heavy-gauge stainless durability

Heavy-gauge stainless steel pots offer exceptional durability and resistance to warping under high pressure, ensuring long-lasting performance in pressure-cooking. In contrast, ceramic-coated pots provide a non-stick surface but may be more prone to chipping and wear over time, reducing their lifespan under intense cooking conditions.

Non-leaching ceramic barrier

Stainless steel pots are preferred in pressure cooking for their durability and non-reactive surface that prevents leaching, ensuring food safety. Ceramic-coated pots provide a non-leaching ceramic barrier that resists acidic and alkaline foods, maintaining flavor integrity and reducing chemical transfer during high-pressure cooking.

Nickel-free stainless claim

Nickel-free stainless steel pots offer superior durability and corrosion resistance without the risk of nickel allergies, making them a safer choice for pressure-cooking compared to ceramic-coated pots, which may degrade over time. Stainless steel's non-reactive surface ensures even heat distribution and long-lasting performance, while ceramic coatings can chip and expose underlying metals during high-pressure cooking.

Micro-cracking ceramic risk

Stainless steel pots offer superior durability and resistance to micro-cracking compared to ceramic-coated pots, which are prone to developing tiny fractures under high-pressure cooking conditions, potentially leading to coating degradation and reduced lifespan. The absence of ceramic layers in stainless steel pressure cookers ensures consistent heat distribution and long-term performance without the risk of micro-cracking that can compromise ceramic-coated surfaces.

Rapid thermal response

Stainless steel pressure-cooking pots offer rapid thermal response due to their excellent heat conductivity and durability, ensuring even heat distribution and quick temperature adjustments. Ceramic-coated pressure cookers provide a non-stick surface but generally have slower thermal response times, which can result in less efficient heat transfer and longer cooking durations.

Eco-glaze ceramic coatings

Stainless steel pressure cooker pots ensure durability and superior heat conduction, while ceramic-coated pots with eco-glaze provide a non-toxic, eco-friendly surface that resists scratching and chemical leaching. Eco-glaze ceramic coatings enhance pressure-cooking by offering easy cleanup and maintaining food purity, making them ideal for health-conscious and environmentally aware users.

Pressure-seal consistency

Stainless steel pressure cooker pots provide superior pressure-seal consistency due to their rigid construction and precise fitting lids, minimizing steam leaks during cooking. Ceramic-coated pots may offer non-stick benefits but often face challenges maintaining the airtight pressure needed for optimal pressure-cooking performance.

Scratch-resistance longevity

Stainless steel pressure-cooking pots offer superior scratch resistance and long-term durability due to their robust metal construction, maintaining performance over years of use. Ceramic-coated pressure cookers, while providing non-stick benefits, tend to be more prone to chipping and scratching, which can reduce their lifespan and compromise cooking efficiency.

Porosity-induced flavor retention

Stainless steel pots exhibit low porosity, preventing flavor absorption and ensuring pure taste retention during pressure-cooking, while ceramic-coated pots, due to their slightly porous surfaces, can retain some flavors over time, potentially influencing the taste of subsequent dishes. The non-porous nature of stainless steel also enhances durability and ease of cleaning, making it preferable for maintaining consistent flavor profiles in pressure-cooked meals.

Stainless steel pot vs Ceramic-coated pot for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com