Metal pressure cookers offer superior heat conductivity and durability, making them ideal for rapid, high-pressure cooking. Ceramic pressure vessels provide even heat distribution and are less reactive with acidic foods, preserving flavor and nutrients. Choosing between the two depends on the cooking style, with metal excelling in speed and ceramic in gentle, consistent cooking.

Table of Comparison

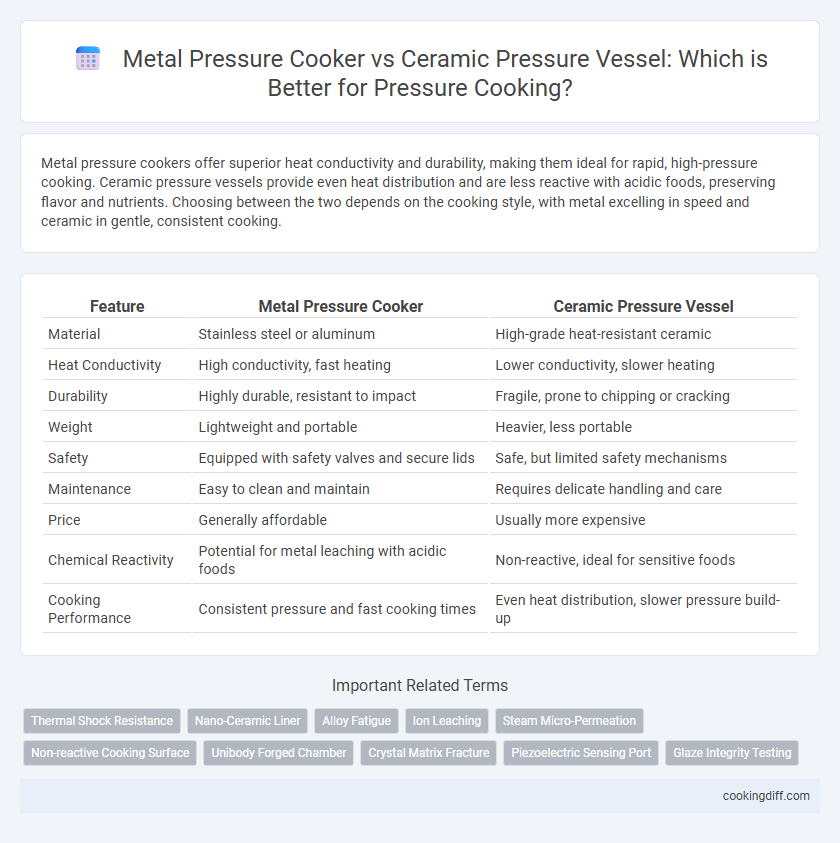

| Feature | Metal Pressure Cooker | Ceramic Pressure Vessel |

|---|---|---|

| Material | Stainless steel or aluminum | High-grade heat-resistant ceramic |

| Heat Conductivity | High conductivity, fast heating | Lower conductivity, slower heating |

| Durability | Highly durable, resistant to impact | Fragile, prone to chipping or cracking |

| Weight | Lightweight and portable | Heavier, less portable |

| Safety | Equipped with safety valves and secure lids | Safe, but limited safety mechanisms |

| Maintenance | Easy to clean and maintain | Requires delicate handling and care |

| Price | Generally affordable | Usually more expensive |

| Chemical Reactivity | Potential for metal leaching with acidic foods | Non-reactive, ideal for sensitive foods |

| Cooking Performance | Consistent pressure and fast cooking times | Even heat distribution, slower pressure build-up |

Introduction to Pressure-Cooking: Metal vs Ceramic Vessels

Metal pressure cookers, typically made from stainless steel or aluminum, offer excellent heat conductivity and durability, making them a popular choice for pressure-cooking. Ceramic pressure vessels provide a non-reactive, chemical-free cooking environment that preserves food flavor and nutrients but often conduct heat less efficiently than metal. Both types require careful pressure management to ensure safety and optimal cooking performance in pressure-cooking applications.

Material Composition: Metal vs Ceramic Pressure Cookers

Metal pressure cookers, typically made from stainless steel or aluminum, offer superior heat conduction and durability compared to ceramic pressure vessels, which are composed of clay or porcelain materials that provide natural non-reactive cooking surfaces. Ceramic pressure cookers are less common but favored for their chemical inertness and aesthetic appeal despite slower heating and potential fragility.

- Metal Composition - Stainless steel and aluminum metals ensure efficient heat distribution and structural strength essential for high-pressure cooking.

- Ceramic Material - Ceramic pressure vessels utilize non-porous clay or porcelain, reducing chemical interactions with food and promoting natural cooking flavors.

- Durability Comparison - Metal vessels withstand repeated high-pressure cycles without cracking, whereas ceramic models require cautious handling due to brittleness.

Heat Conductivity and Efficiency Comparison

Metal pressure cookers exhibit superior heat conductivity due to materials like aluminum and stainless steel, enabling faster and more efficient pressure buildup. Ceramic pressure vessels, while aesthetically pleasing, have lower thermal conductivity, which can result in longer cooking times and uneven heat distribution.

- Metal Heat Conductivity - Metals such as aluminum conduct heat rapidly, improving cooking speed and energy efficiency.

- Ceramic Thermal Properties - Ceramic vessels retain heat well but transfer heat slowly, affecting pressure consistency.

- Energy Efficiency - Metal pressure cookers generally consume less energy by reaching optimal pressure quicker than ceramic alternatives.

Choosing between metal and ceramic pressure cookers depends on prioritizing rapid heating versus heat retention qualities.

Durability and Longevity of Metal vs Ceramic

Which material offers better durability and longevity for pressure-cooking, metal or ceramic pressure vessels? Metal pressure cookers, typically made from stainless steel or aluminum, provide superior strength and resistance to impact, ensuring long-term use without cracking or chipping. Ceramic pressure vessels are more prone to fractures under high pressure but offer excellent heat retention, making them less durable for intense pressure-cooking applications.

Safety Features: Metal Pressure Cookers vs Ceramic Vessels

Metal pressure cookers are equipped with robust safety features such as pressure release valves and locking lids that prevent accidental opening under pressure. Their durable stainless steel or aluminum construction ensures consistent performance and heat resistance, reducing risks of explosion or rupture.

Ceramic pressure vessels offer excellent heat retention and non-reactive surfaces, but often lack integrated pressure indicators and advanced safety locks found in metal cookers. While aesthetically appealing, ceramic vessels require careful handling due to their brittle nature, increasing the potential safety hazards during high-pressure cooking.

Maintenance and Cleaning: Which Is Easier?

Metal pressure cookers typically require less maintenance as their stainless steel or aluminum surfaces resist stains and are dishwasher-safe. Ceramic pressure vessels need careful handling to prevent chipping and often require mild cleaners to maintain their non-stick properties.

Cleaning metal pressure cookers is straightforward since they endure scrubbing and abrasive cleaners, making them convenient for daily use. Ceramic pressure vessels demand gentle cleaning to avoid surface damage and usually cannot withstand harsh detergents or metal scrubbers. Regular upkeep of ceramic cookers also involves monitoring for cracks or discoloration that could affect cooking safety and performance.

Flavor and Nutrient Retention Differences

| Material | Flavor Retention | Nutrient Retention |

| Metal Pressure Cooker | Often imparts a slight metallic taste over time, especially with acidic foods. | High heat conductivity preserves nutrients efficiently but may cause slight degradation of heat-sensitive vitamins. |

| Ceramic Pressure Vessel | Neutral surface prevents flavor alteration, maintaining natural food taste. | Gentle heat distribution enhances retention of vitamins and antioxidants compared to metal. |

Compatibility with Stovetops and Cookers

Metal pressure cookers are compatible with a wide range of stovetops, including gas, electric, induction, and ceramic glass cookers, due to their magnetic properties and durable construction. Their ability to withstand direct flame and rapid temperature changes makes them versatile for various cooking environments.

Ceramic pressure vessels often require careful consideration of stovetop compatibility, as they are generally suited for electric and ceramic glass cookers but may not work efficiently on induction or open flame gas burners. Their fragile nature demands gradual heating to prevent cracking, limiting their flexibility on high-heat stovetops.

Environmental Impact and Sustainability

Metal pressure cookers, typically made from aluminum or stainless steel, offer durability and recyclability but require significant energy and raw materials for production. Ceramic pressure vessels, while less common, provide energy-efficient cooking with potentially lower carbon footprints but pose challenges in terms of lifespan and recyclability.

- Metal Cookers and Energy Use - Metal pressure cookers often consume more energy during manufacturing but last longer, reducing the frequency of replacement.

- Ceramic Vessels and Carbon Footprint - Ceramic pressure vessels have lower thermal conductivity losses, contributing to energy savings during cooking processes.

- Recyclability Considerations - Metals are widely recyclable, whereas ceramic materials are less recyclable, leading to potential waste concerns.

Related Important Terms

Thermal Shock Resistance

Ceramic pressure vessels exhibit superior thermal shock resistance compared to metal pressure cookers, minimizing the risk of cracking or damage during rapid temperature changes. Metal pressure cookers, while generally more durable under high pressure, can experience deformation or warping when exposed to sudden thermal fluctuations.

Nano-Ceramic Liner

Nano-ceramic liners in ceramic pressure cookers provide superior heat retention and even heat distribution compared to traditional metal pressure cookers, enhancing cooking efficiency and food flavor. These nano-ceramic coatings also offer non-toxic, scratch-resistant, and easy-to-clean surfaces that resist corrosion better than metal vessels, making them a healthier and longer-lasting choice for pressure cooking.

Alloy Fatigue

Metal pressure cookers, typically made from stainless steel or aluminum alloys, exhibit higher resistance to alloy fatigue due to their ability to withstand repeated high-pressure cycles without significant deformation. Ceramic pressure vessels, while offering excellent thermal insulation and chemical inertness, are more prone to cracking and structural failure under continuous pressure variations because of their brittle nature and lower tolerance to alloy fatigue.

Ion Leaching

Metal pressure cookers, typically made from stainless steel or aluminum, can leach trace amounts of ions such as aluminum or nickel into food during high-temperature pressure cooking, especially when acidic ingredients are used. Ceramic pressure vessels are generally inert and resistant to ion leaching, offering a safer option for preserving food purity and preventing possible metallic contamination.

Steam Micro-Permeation

Metal pressure cookers exhibit minimal steam micro-permeation due to their dense, non-porous surfaces, ensuring efficient pressure build-up and retention during cooking. In contrast, ceramic pressure vessels may allow slight steam micro-permeation through microscopic pores, potentially affecting pressure consistency and cooking times.

Non-reactive Cooking Surface

Metal pressure cookers with stainless steel interiors provide a non-reactive cooking surface that prevents food from absorbing metallic tastes and resists corrosion during high-pressure cooking. Ceramic pressure vessels offer a naturally non-reactive surface that ensures even heat distribution and maintains flavor purity without leaching chemicals or metals into the food.

Unibody Forged Chamber

Metal pressure cookers with unibody forged chambers offer superior durability and heat conductivity compared to ceramic pressure vessels, ensuring even cooking and enhanced safety under high pressure. The forged construction in metal cookers minimizes potential weak points, delivering consistent performance and longevity ideal for intensive pressure-cooking applications.

Crystal Matrix Fracture

Metal pressure cookers offer superior durability and resistance to Crystal Matrix Fracture due to their homogeneous metallic structure, while ceramic pressure vessels are more prone to micro-cracks and fractures under high pressure because of their brittle, crystalline nature. The inherent toughness and ductility of metals make them safer and more reliable for repeated high-pressure cooking cycles compared to ceramic materials.

Piezoelectric Sensing Port

Metal pressure cookers with piezoelectric sensing ports offer enhanced durability and precise pressure monitoring due to their high thermal conductivity and mechanical strength. In contrast, ceramic pressure vessels provide superior chemical inertness and heat resistance but may face challenges in integrating reliable piezoelectric sensors for accurate pressure detection.

Metal pressure cooker vs Ceramic pressure vessel for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com