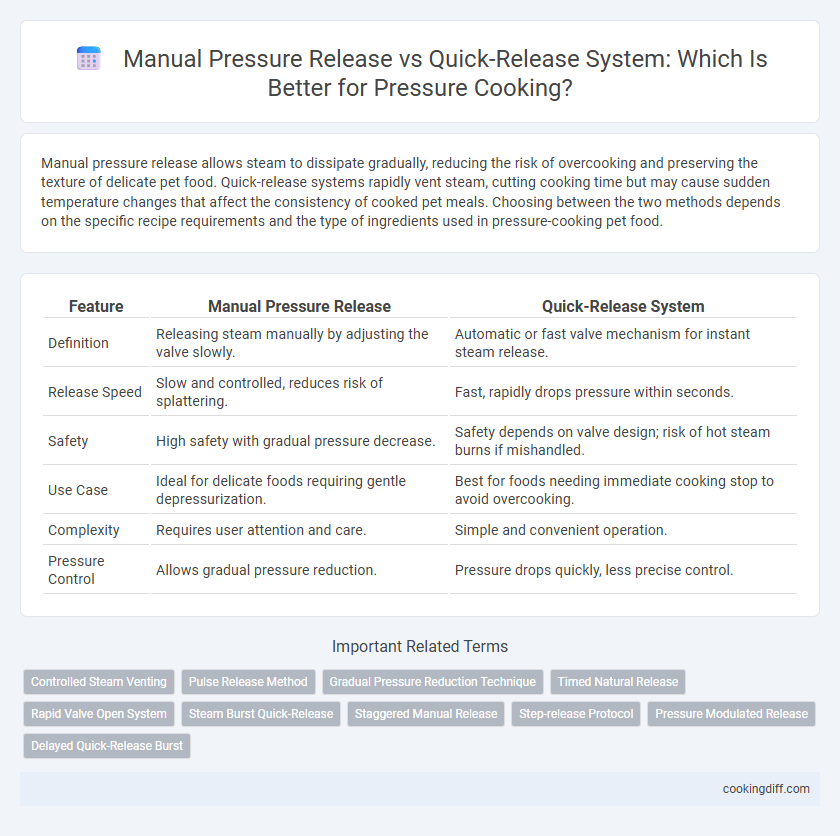

Manual pressure release allows steam to dissipate gradually, reducing the risk of overcooking and preserving the texture of delicate pet food. Quick-release systems rapidly vent steam, cutting cooking time but may cause sudden temperature changes that affect the consistency of cooked pet meals. Choosing between the two methods depends on the specific recipe requirements and the type of ingredients used in pressure-cooking pet food.

Table of Comparison

| Feature | Manual Pressure Release | Quick-Release System |

|---|---|---|

| Definition | Releasing steam manually by adjusting the valve slowly. | Automatic or fast valve mechanism for instant steam release. |

| Release Speed | Slow and controlled, reduces risk of splattering. | Fast, rapidly drops pressure within seconds. |

| Safety | High safety with gradual pressure decrease. | Safety depends on valve design; risk of hot steam burns if mishandled. |

| Use Case | Ideal for delicate foods requiring gentle depressurization. | Best for foods needing immediate cooking stop to avoid overcooking. |

| Complexity | Requires user attention and care. | Simple and convenient operation. |

| Pressure Control | Allows gradual pressure reduction. | Pressure drops quickly, less precise control. |

Introduction to Pressure-Cooking Release Methods

Manual pressure release involves allowing the pressure to decrease slowly and naturally inside the cooker, which helps preserve the texture and moisture of delicate ingredients. This method is ideal for stews, soups, and large cuts of meat that benefit from gradual cooling.

Quick-release systems rapidly vent steam through a valve, significantly reducing cooking time by immediately lowering the pressure. This technique is suitable for vegetables and seafood that require precise, short cooking to prevent overcooking.

Defining Manual Pressure Release

| Manual Pressure Release: A method for reducing pressure inside a pressure cooker by carefully turning the venting knob or valve to allow steam to escape slowly and safely. |

| This technique provides gradual depressurization, minimizing risks of food splattering or overcooking delicate ingredients. |

| Manual pressure release is essential for recipes requiring controlled pressure reduction to preserve texture and flavor integrity. |

Understanding Quick-Release System

The quick-release system in pressure cookers rapidly vents steam to reduce internal pressure quickly, allowing for immediate lid removal. This method is ideal for delicate foods that require precise cooking times to avoid overcooking or loss of texture.

- Rapid steam release - The mechanism quickly expels pressure by opening a valve, preventing prolonged cooking.

- Safety feature - Designed to prevent accidents by controlling steam release in a manageable way.

- Controlled pressure drop - Allows users to stop cooking immediately, helping preserve flavor and nutrients.

Using the quick-release system effectively enhances cooking control and food quality in pressure-cooking.

Key Differences Between Manual and Quick-Release

Manual pressure release gradually lowers the pressure by letting steam escape slowly, preserving food texture and preventing splatter. Quick-release rapidly vents steam through a valve, drastically reducing cooking time but can cause foaming in some dishes.

- Pressure Reduction Speed - Manual release takes several minutes, while quick-release happens in seconds.

- Food Texture Impact - Manual release better maintains delicate textures; quick-release may cause tougher or overcooked results.

- Safety and Handling - Manual release minimizes hot steam bursts; quick-release requires cautious handling to avoid burns.

Safety Considerations for Both Techniques

Manual pressure release requires careful handling to avoid steam burns by slowly turning the valve and keeping hands away from the steam vent. Quick-release systems eject steam rapidly, increasing the risk of splattering hot liquid if not directed safely.

- Steam Burns Risk - Manual release minimizes sudden steam exposure, reducing burn hazards compared to quick-release methods.

- Pressure Stability - Quick-release can cause rapid pressure drops that may affect food texture or cause safety valve triggers.

- User Precautions - Both methods necessitate using protective tools and maintaining distance from the steam outlet to prevent injuries.

Cooking Outcomes: Flavor and Texture Impact

Manual pressure release allows gradual depressurization, which helps preserve moisture and results in more tender textures, ideal for delicate ingredients like fish or vegetables. Quick-release systems rapidly drop pressure, often causing tougher textures and less infused flavors due to abrupt cooking interruptions.

Slow pressure release enhances flavor development by letting ingredients rest and continue cooking gently, deepening aromatic profiles. Quick-release can lead to uneven cooking and moisture loss, negatively impacting both taste and texture. Chefs often prefer manual release for recipes requiring precise texture and richer flavor retention.

Suitable Recipes for Manual vs Quick-Release

Manual pressure release suits recipes requiring gentle steam release to prevent overcooking, such as soups, stews, and tough cuts of meat. This method retains moisture and enhances flavor by allowing gradual pressure decrease.

Quick-release systems are ideal for delicate foods like vegetables, seafood, and pasta that benefit from immediate pressure drop to preserve texture and color. Rapid steam expulsion prevents overcooking and maintains firmness in these quick-cooking recipes.

Time Efficiency and Convenience Comparison

Manual pressure release requires gradually turning the valve to slowly reduce pressure, typically taking 10 to 20 minutes, which preserves food texture but consumes more time. Quick-release systems rapidly vent steam within seconds, significantly reducing cooking downtime and enhancing convenience for busy cooks. Choosing between the two depends on balancing desired texture retention with the need for time-efficient meal preparation.

Tips for Choosing the Best Release Technique

Which pressure release method ensures optimal cooking results and safety in a pressure cooker? Manual pressure release allows gradual depressurization, preserving texture and flavor in delicate foods, while quick-release rapidly vents steam, ideal for preventing overcooking and reducing wait time. Consider the specific recipe and ingredient sensitivity when selecting between manual and quick-release systems for the best outcome.

Related Important Terms

Controlled Steam Venting

Manual pressure release allows for precise control over steam venting by gradually releasing pressure, reducing the risk of food splattering or overcooking. Quick-release systems rapidly vent steam through a valve, providing speed but less control, which may cause sudden temperature drops and affect texture-sensitive dishes.

Pulse Release Method

The Pulse Release Method in pressure cooking involves intermittently releasing pressure in short bursts, balancing the benefits of manual pressure release and quick-release systems by preventing overcooking and avoiding sudden steam bursts. This technique optimizes texture and flavor retention, especially for delicate ingredients like vegetables and seafood.

Gradual Pressure Reduction Technique

The Gradual Pressure Reduction Technique in manual pressure release allows steam to escape slowly, preventing overcooking and preserving texture and flavor. This method enhances control over the cooking process compared to the rapid depressurization of quick-release systems, which can cause food to become dry or tough.

Timed Natural Release

Timed natural release in pressure-cooking allows the pressure to drop gradually without venting steam, preserving moisture and enhancing the texture of delicate foods. This method reduces the risk of overcooking and prevents splattering that can occur with quick-release systems, making it ideal for recipes requiring gentle finishes.

Rapid Valve Open System

The Rapid Valve Open System in pressure cookers enables quick-release of steam by allowing immediate valve opening, reducing cooking time and preventing overcooking of delicate ingredients. This manual pressure release method enhances safety by controlling steam flow while preserving food texture and nutrients, making it ideal for recipes requiring swift pressure drops.

Steam Burst Quick-Release

Steam burst quick-release in pressure cooking rapidly expels steam through a targeted vent, minimizing cooking time and preventing food overcooking or mushiness. This system contrasts with manual pressure release, which requires careful monitoring and gradual depressurization to avoid burns and maintain texture integrity.

Staggered Manual Release

Staggered manual release in pressure cooking involves gradually opening the valve over time to safely reduce pressure, minimizing food splatter and preserving texture. This method combines the controlled safety of manual release with the efficiency of quick-release systems, enhancing cooking precision and preventing overcooking.

Step-release Protocol

The step-release protocol combines manual pressure release and quick-release methods to gradually reduce pressure, minimizing food splatter and preserving texture. This technique ensures safer handling by allowing steam to escape in controlled increments, making it ideal for delicate ingredients.

Pressure Modulated Release

Pressure Modulated Release (PMR) offers a balanced approach between manual pressure release and quick-release systems by gradually reducing pressure to prevent food overcooking and minimize splattering. This method optimizes cooking efficiency and safety by allowing controlled pressure adjustment, enhancing texture retention and reducing nutrient loss in pressure-cooked meals.

Manual pressure release vs Quick-release system for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com