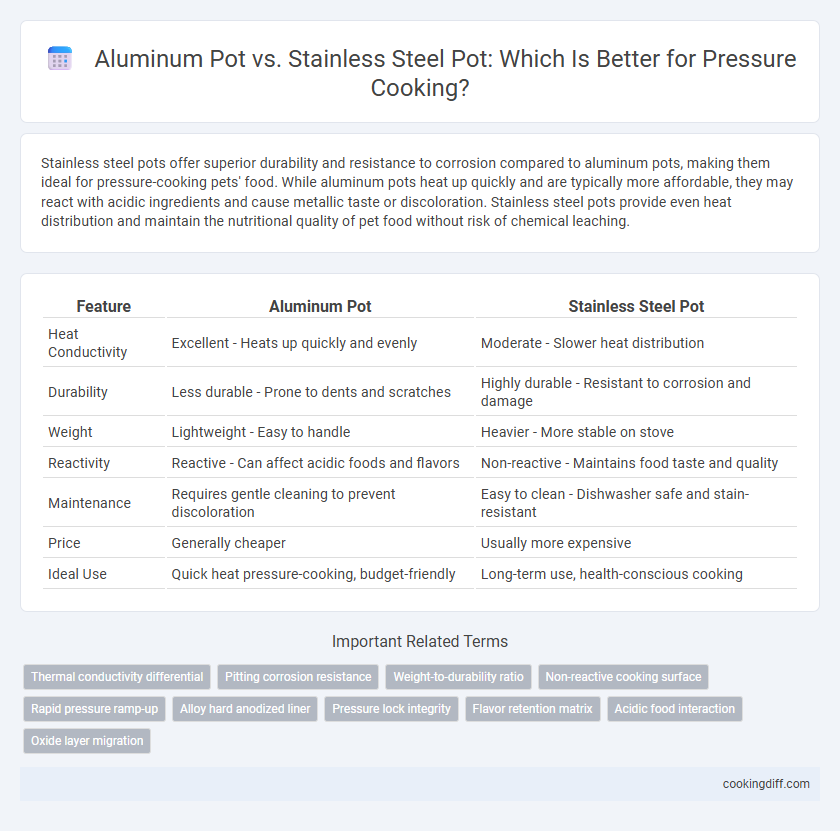

Stainless steel pots offer superior durability and resistance to corrosion compared to aluminum pots, making them ideal for pressure-cooking pets' food. While aluminum pots heat up quickly and are typically more affordable, they may react with acidic ingredients and cause metallic taste or discoloration. Stainless steel pots provide even heat distribution and maintain the nutritional quality of pet food without risk of chemical leaching.

Table of Comparison

| Feature | Aluminum Pot | Stainless Steel Pot |

|---|---|---|

| Heat Conductivity | Excellent - Heats up quickly and evenly | Moderate - Slower heat distribution |

| Durability | Less durable - Prone to dents and scratches | Highly durable - Resistant to corrosion and damage |

| Weight | Lightweight - Easy to handle | Heavier - More stable on stove |

| Reactivity | Reactive - Can affect acidic foods and flavors | Non-reactive - Maintains food taste and quality |

| Maintenance | Requires gentle cleaning to prevent discoloration | Easy to clean - Dishwasher safe and stain-resistant |

| Price | Generally cheaper | Usually more expensive |

| Ideal Use | Quick heat pressure-cooking, budget-friendly | Long-term use, health-conscious cooking |

Introduction: Aluminum vs Stainless Steel Pots for Pressure-Cooking

Aluminum pots heat up quickly and offer excellent thermal conductivity, making them efficient for pressure-cooking. Stainless steel pots provide superior durability and resistance to corrosion, ensuring long-term use and safety.

- Thermal Conductivity - Aluminum conducts heat faster than stainless steel, reducing cooking times.

- Durability - Stainless steel resists dents and scratches better than aluminum, enhancing lifespan.

- Maintenance - Aluminum may discolor or react with acidic foods, while stainless steel remains non-reactive and easier to clean.

Heat Conductivity: Which Material Cooks Faster?

| Material | Heat Conductivity (W/m*K) | Cooking Speed |

|---|---|---|

| Aluminum | 205 | Faster heat transfer, resulting in quicker pressure buildup and shorter cooking time. |

| Stainless Steel | 16 | Lower heat conductivity causes slower heat transfer, extending cooking duration compared to aluminum. |

Durability and Longevity: Aluminum or Stainless Steel?

Stainless steel pots offer superior durability and resistance to warping under high pressure compared to aluminum pots. Aluminum pots, while lightweight and excellent for heat conduction, tend to degrade faster over time due to corrosion and wear.

- Stainless steel resists corrosion - It maintains strength and appearance even after prolonged use in pressure cooking.

- Aluminum is prone to oxidation - This can weaken the pot's structure and reduce its lifespan.

- Stainless steel endures high pressure - Ideal for long-term use in pressure cookers without deformation.

Choosing stainless steel ensures a longer-lasting pressure cooker pot with consistent performance.

Safety Concerns: Health Implications of Each Material

Aluminum pots, commonly used in pressure cooking, may pose health concerns due to aluminum leaching into food, especially with acidic ingredients, which can pose risks for neurological health over prolonged exposure. Stainless steel pots are favored for their non-reactive properties and durability, significantly reducing the risk of metal contamination during high-pressure cooking.

Stainless steel pressure cookers are generally considered safer, as they do not release harmful substances when heated or scratched. While aluminum pots offer excellent heat conduction, their potential for corrosion and aluminum leaching raises safety concerns. Choosing stainless steel minimizes health risks, providing a safer cooking environment for pressure-cooking applications.

Maintenance and Cleaning: Effort Required for Each Type

Which type of pot requires less effort for cleaning after pressure-cooking, aluminum or stainless steel? Aluminum pots tend to stain and discolor more easily, demanding more frequent and careful cleaning to maintain their appearance. Stainless steel pots resist staining and corrosion, allowing for easier maintenance and simpler cleaning routines.

Weight and Handling: User Experience in the Kitchen

Aluminum pots for pressure-cooking are significantly lighter, enhancing ease of handling and reducing fatigue during kitchen tasks. Stainless steel pots offer greater durability but are heavier, which can impact maneuverability and comfort when lifting or moving. Choosing between aluminum and stainless steel depends on the user's preference for lightweight convenience versus robust construction in pressure-cooking.

Affordability: Cost Comparison for Pressure-Cookers

Aluminum pressure cookers are generally more affordable, making them a popular choice for budget-conscious buyers. Stainless steel pots tend to have a higher upfront cost but offer greater durability and resistance to corrosion. Over time, the longevity of stainless steel can provide better value despite the initial price difference.

Compatibility with Stovetops: Gas, Electric, Induction

Aluminum pots excel in heat conductivity, making them efficient for gas and electric stovetops but generally incompatible with induction cooktops due to their non-magnetic nature. Stainless steel pots, often with a magnetic base, offer broad compatibility across gas, electric, and induction stovetops, providing versatility for pressure-cooking.

Gas stovetops benefit from aluminum's quick heating properties, while stainless steel's durability suits longer cooking times on electric and induction surfaces. Choosing stainless steel pots with a ferromagnetic base ensures optimal performance on all stovetop types, including induction, enhancing pressure-cooking efficiency.

Flavor Impact: Influence of Pot Material on Food Taste

Aluminum pots tend to react with acidic foods, subtly altering the taste during pressure cooking. Stainless steel pots maintain a neutral flavor profile, preserving the original taste of ingredients more effectively.

- Aluminum Reactivity - Aluminum can impart a metallic taste when cooking highly acidic dishes such as tomato-based stews.

- Flavor Preservation - Stainless steel does not react with food, ensuring the flavors remain true to the recipe.

- Food Safety - Stainless steel is less likely to leach materials into food, enhancing flavor safety and consistency.

Related Important Terms

Thermal conductivity differential

Aluminum pots exhibit higher thermal conductivity, allowing faster and more even heat distribution during pressure cooking compared to stainless steel pots, which have lower thermal conductivity and may heat less uniformly. This difference significantly affects cooking efficiency and temperature control, with aluminum facilitating quicker pressure buildup and consistent cooking results.

Pitting corrosion resistance

Stainless steel pots offer superior resistance to pitting corrosion compared to aluminum pots, making them more durable under the high-pressure and moisture conditions of pressure cooking. Aluminum pots are prone to pitting corrosion due to their reactive nature, which can compromise safety and cookware longevity.

Weight-to-durability ratio

Aluminum pressure cooker pots offer a lightweight advantage making them easier to handle and ideal for frequent use but tend to be less durable and prone to warping over time compared to stainless steel pots. Stainless steel pressure cookers provide a superior weight-to-durability ratio with heavier construction that resists corrosion and deformation, ensuring long-term reliability despite their increased weight.

Non-reactive cooking surface

Stainless steel pots offer a non-reactive cooking surface ideal for pressure cooking, preventing metallic taste transfer and preserving food flavor. Aluminum pots, while excellent heat conductors, can react with acidic or alkaline ingredients, potentially causing discoloration and off-flavors.

Rapid pressure ramp-up

Aluminum pots heat up quickly due to their excellent thermal conductivity, enabling a rapid pressure ramp-up in pressure-cooking. Stainless steel pots, while slower to heat, offer superior durability and resistance to corrosion, which may influence the overall cooking efficiency depending on the specific model and thickness.

Alloy hard anodized liner

Alloy hard anodized liners in pressure cookers provide superior durability and corrosion resistance compared to traditional aluminum and stainless steel pots, enhancing heat conductivity and ensuring even cooking. These liners offer a non-reactive surface, preventing food contamination while maintaining structural integrity under high pressure and temperature.

Pressure lock integrity

Aluminum pots offer excellent heat conductivity but may warp over time, compromising the pressure lock integrity in pressure cooking. Stainless steel pots maintain superior durability and consistent sealing performance, ensuring reliable pressure lock integrity throughout extended use.

Flavor retention matrix

Aluminum pots conduct heat quickly and evenly, which can enhance flavor retention by maintaining consistent pressure and temperature throughout the cooking process. Stainless steel pots, while slower to heat, resist flavor transfer and corrosion, preserving the purity of the ingredients' taste under high-pressure conditions.

Acidic food interaction

Aluminum pots react with acidic foods during pressure cooking, often causing metallic taste transfer and potential discoloration, which can affect dish quality and pot longevity. Stainless steel pots resist acid corrosion, maintaining flavor integrity and ensuring durability for cooking acidic ingredients under pressure.

Aluminum pot vs Stainless steel pot for pressure-cooking. Infographic

cookingdiff.com

cookingdiff.com